Asphalt Mixing Plant 40-320tph Asphalt Mixers Factory Price

- $100000.00 /set

- 1 set

- Henan ZOOMLINE Machinery Co., Ltd.

- Henan, China

- Mr ZOOMLINE MACHINERY

| Dimensions (L*W*H): | According to the asphalt plant model | Supply capacity: | 20 sets per month |

| Showroom location: | Egypt, Indonesia, Pakistan, India, Russia, Thailand, Bangladesh, Kazakhstan, Ukraine, Kyrgyzstan, Uzbekistan, None | color: | customer request |

| Package preview: | Control System: | PLC+color touch screen | |

| Warranty: | 1 year | Packaging Details: | Asphalt mixing plant 40-320tph asphalt mixer needs: 40HQ container |

| port: | Qingdao/Shanghai/Tianjin; Inland ports: Alashankou/Erlianluote/Manzhouli/Hekou | Voltage: | 220V/380V-50Hz |

| brand: | Amplifying line | Blender capacity: | 500-4000kg/batch |

| weight: | 50000 kg | payment terms: | L/C, Western Union, D/P, D/A, T/T, Moneygram, Installment payment |

| product name: | Asphalt mixing plant 40-320tph asphalt mixer factory price | strength: | According to the asphalt plant model |

| Mechanical test report: | if | Applicable industries: | Manufacturing plants, construction projects, road construction machinery |

| Core component warranty: | 1 year | Model: | ZAP-S40-320 |

| place of origin; place of origin: | Henan, China | Unique selling point: | reliable quality |

| Marketing Type: | normal product | Dust removal method: | Gravity Dust Collector + Pocket Dust Collector |

| Weighing system: | METTLER TOLEDO | Serve: | Technical Services |

| Core components: | PLC, engine, bearing, gearbox, motor, pressure vessel, gear, pump | State of health: | new |

| Video shipment inspection: | if |

Asphalt mixing plant 40-320tph asphalt mixer factory price

Main Features of ZAP-S Series 40-320tphAsphalt mixing plant:

1. ZAP-S series stationary asphalt mixing equipment is a product that combines various advantages of western models. It adopts modular design, compact structure, and is easy to assemble and transport.

2. The components adopt international famous brands, keep pace with international advanced technology, and can ensure the high reliability and safety of long-term operation of the equipment.

3. Each piece of equipment has undergone strict trial assembly and test machine before leaving the factory to ensure stable product quality and high standards.

4. Adopt human-machine interface and PLC control system, perfect human-computer interaction function, easy to operate; have manual, semi-automatic, automatic control functions; have remote fault detection and maintenance functions, and can solve problems in the first time.

5. Reasonable and diverse layout methods can be changed according to different requirements to better adapt to actual construction requirements.

6. Excellent expandability, ZAP-S series asphalt batch mixing plant can add RAP, wood fiber adding equipment, etc., to meet more requirements.

7. Large and solid installation base makes installation easier.

8. Low consumption, high efficiency and environmental protection design, it is an ideal choice for various roads.

ZAP-S series asphalt mixing plant technical parameters:

| project | ZAP-S40 | ZAP-S60 | ZAP-S80 | ZAP-S100 | ZAP-S120 | ZAP-S160 | ZAP-S200 | ZAP-S240 | ZAP-S320 |

| Factory capacity | 40 tons/hour | 60 tons/hour | 80 tons/hour | 100 tons/hour | 120 tons/hour | 160 tons/hour | 200 tons/hour | 240 tons/hour | 320 tons/hour |

| Cold Aggregate Feeding System | |||||||||

| Hopper capacity | 4×4.5 cubic meters | 4×4.5 cubic meters | 4×6.5 cubic meters | 4×6.5 cubic meters | 4×8 cubic meters | 5×8 cubic meters | 5×15 cubic meters | 5×15 cubic meters | 6×15 cubic meters |

| belt capacity | 60 tons/hour | 80 tons/hour | 100 tons/hour | 120 tons/hour | 140 tons/hour | 180 tons/hour | 220 tons/hour | 280 tons/hour | 360 tons/hour |

| drying system | |||||||||

|

Drying drum size (mm) |

1200x5200 | 1200x5500 | 1500x6600 | 1500x6600 | 1800x8000 | 1900x9000 | 2200x9000 | 2600x9500 | 2800x10200 |

| drying capacity | 40-60 tons/hour | 60-70 tons/hour | 80-100 tons/hour | 100-120 tons/hour | 120-140 tons/hour | 160-180 tons/hour | 200-220 tons/hour | 240-260 tons/hour | 320-360 tons/hour |

| burner (oil) | 70-300kg/hour | 100-400kg/hour | 60-600kg/hour | 100-1000kg/hour | 100-1000kg/hour | 140-1400 kg/h | 180-1800 kg/h | 180-1800 kg/h | 250-2500 kg/h |

| Fuel Consumption (Oil) | 6.5-7kg/ton | 6.5-7kg/ton | 6.5-7kg/ton | 6.5-7kg/ton | 6.5-7kg/ton | 6.5-7kg/ton | 6.5-7kg/ton | 6.5-7kg/ton | 6.5-7kg/ton |

| stirring tower | |||||||||

| Screen | 4th floor | 4th floor | 4th floor | 4th floor | 4th floor | 4/5 floors | 5th floor | 5th floor | layer 6 |

| Aggregate weighing | 3x500kg | 3x1000kg | 3x1000kg | 3x1500kg | 3x1500kg | 3x2000kg | 3x3000kg | 3x3000kg | 3x5000kg |

| asphalt weighing | 3x100kg | 3x100kg | 3x100kg | 3x200kg | 3x200kg | 3x200kg | 3x500kg | 3x500kg | 3x500kg |

| Filling weighing | 3x100kg | 3x100kg | 3x100kg | 3x200kg | 3x200kg | 3x200kg | 3x500kg | 3x500kg | 3x500kg |

| Blender capacity | 500 kg | 800 kg | 1000 kg | 1300 kg | 1500 kg | 2000 kg | 2500 kg | 3000 kg | 4000 kg |

| stirring cycle | 45s | 45s | 45s | 45s | 45s | 45s | 45s | 45s | 45s |

| Dust removal system | |||||||||

| Baghouse Filtration | 200 square meters | 300 square meters | 430 square meters | 480 square meters | 550 square meters | 650 square meters | 700 square meters | 1050 square meters | 1350 square meters |

| Exhaust fan power | 18.5/22kw | 30/37 kW | 45kw | 55 kW | 2x45 kW | 2x55 kW | 2x75 kW | 2×90kw | 2×110kw |

| asphalt temperature | 140-180℃ | 140-180℃ | 140-180℃ | 140-180℃ | 140-180℃ | 140-180℃ | 140-180℃ | 140-180℃ | 140-180℃ |

| Finished asphalt silo (optional) | 30 tons | 30 tons | 30 tons | 60 tons | 100 tons | 100 tons | 100/200 tons | ||

| total power | -150kw | -180kw | -270kw | -300kw | -390kw | -500kw | -570kw | -640kw | -800kw |

40-320TPH asphalt mixer main components

The asphalt batching and mixing plant mainly includes cold material system, drying system, combustion system, hot material lifting, vibrating screen, hot material storage silo, weighing and mixing system, asphalt supply system, powder supply system, dust removal system, finished product silo, control system etc.

Henan Zhonglian Machinery Co., Ltd. is located in Longsheng Industrial Park, Nanyang City, Henan Province, China. To be a professional supplier of asphalt mixing plants, recycled asphalt plants, and asphalt equipment, we have a R&D and manufacturing center covering an area of about 50,000 square meters. The leading products include stationary asphalt mixing plants, mobile asphalt mixing plants, continuous drum type asphalt mixing plants, which are widely used in highways, urban roads, bridges and airports.

ZOOMLINE has always aimed at the latest, highest and best goal, and put forward in the financial crisis - "new form, new idea, new measure, new height, new image, new world". After strict training, ZOOMLINE employees combine unique management and manufacturing technology, qualified process verification, rich manufacturing experience and customer-oriented service spirit to produce advanced level products.

Our main products include:

Asphalt mixing plant: intermittent asphalt mixing plant (fixed and mobile), continuous asphalt mixing plant (fixed and mobile), recycled asphalt mixing plant and environmentally friendly asphalt mixing plant.

Burners: pulverized coal burners (for asphalt plants, boilers and other industries), oil burners (heavy oil and diesel type) and gas burners for asphalt plants.

We can also provide other supporting equipment, such as asphalt melting equipment, emulsified asphalt equipment, polymer modified asphalt equipment, additive systems, generators and road repairing machines, etc.

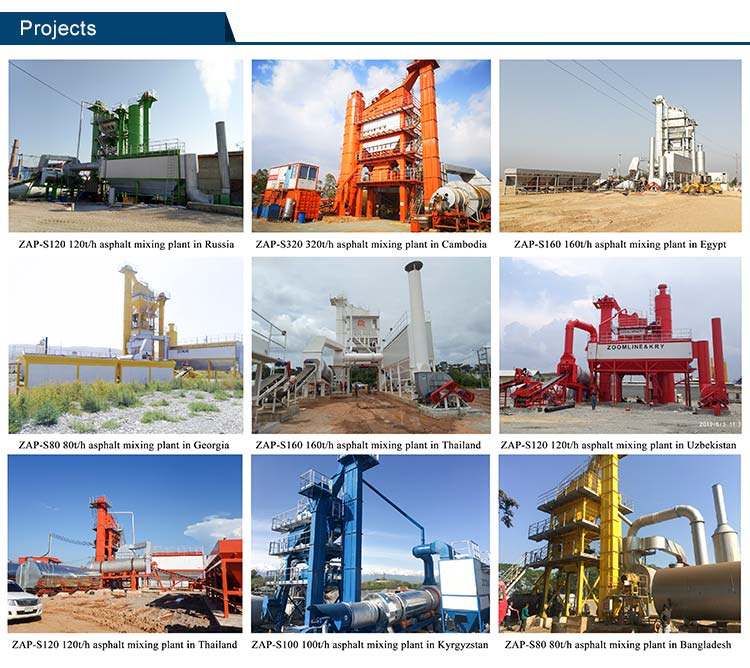

Since the establishment of ZOOMLINE, through continuous technical investment, we have become one of the most reliable construction project partners in China. Our asphalt mixing plants are renowned for their excellent performance. Today, our asphalt mixing plant products have been sold to countries such as Russia, Cambodia, Bangladesh, Egypt, Pakistan, Uzbekistan, Kazakhstan, Kyrgyzstan, Ukraine, Georgia, Indonesia, Belgium and Thailand. Our asphalt mixing plants have obtained CE, ISO, EAC certificates.

|

|

| Mobile Asphalt Mixing Plant | recycled asphalt plant |

|

|

| Drun Mixed Asphalt Plant | A trailer type continuous asphalt mixing plant |

2. All parts of this asphalt station can be put into the container, which can greatly reduce the transportation cost.