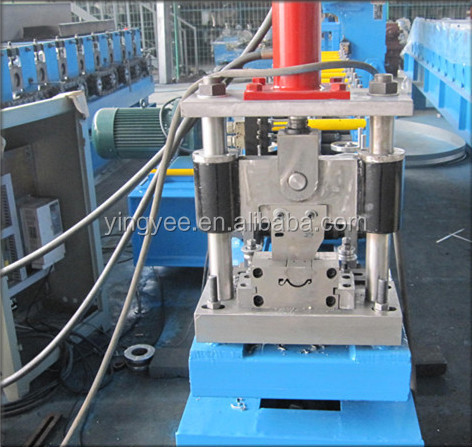

Best Selling Roller Shutter Slat Forming Machine / Roller Shutter Door Making Machine

- $5000.00 /set

- 1 set

- Shijiazhuang Yingyee Import And Export Co., Ltd.

- Hebei, China

- Ms Tania Tian

| Marketing Type: | normal product | Core components: | alarm lock |

| payment terms: | T/T, Western Union | Control System: | Programmable Controllers |

| Showroom location: | not any | Packaging Details: | film and plastic, steel wire |

| Applicable industries: | construction project | Forming speed: | 10-15m/min |

| Health status: | new | Roller material: | #45 Steel, Chrome Plated |

| Supply capacity: | 100 sets per year | Cold rolling mill: | Roller Blind Roller Blind Forming Machine |

| Origin: | Hebei china | Core component warranty: | 1 year |

| Local service location: | not any | Dimensions (L*W*H): | 10000*1200*800 |

| After warranty service: | Video technical support, online support, spare parts, on-site maintenance and repair services | After-sales service provided: | On-site service by overseas engineers, online support, free spare parts, on-site installation and commissioning training, on-site maintenance and repair services, video technical support |

| Voltage: | 380v 3 phase 60Hz or as buyer's request | Warranty: | 1 year |

| Power (watts): | 15KW | Video shipment inspection: | if |

| Material Thickness: | 0.8-1.5mm | type: | cold rolling mill |

| port: | Tianjin Xingang | brand: | Yingyi |

| Mechanical test report: | if |

The main technical parameters:

1. Material thickness: 0.8-1.5mm

2. Forming steps: 13 groups

3. Forming speed: 10-15m/min

4. Shaft material: #45 steel

5. Shaft diameter: ¢48

6. Roller material: #45 steel, chrome plated

7. Molding power: 3.0KW

8. Cutting power: 1.5KW

9. Tool type: hydraulic flying saw

10. Control system: PLC (Omron brand)

11. Machine size (length x width x height): 6 x 0.8 x 1 M

12. Total weight: 2T

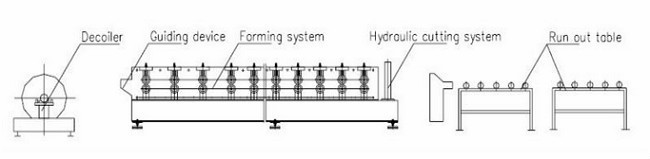

production process:

Uncoiler---straightening machine---punching machine---forming machine---hydraulic cutting device---discharging frame

This is an efficient die-changing model machine for sheet metal. This machine is widely used in all walks of life, especially suitable for small and medium batches of metal sheet production lines, and various punching and forming.

Profile Profile Metal Roof Sheet Roll Forming Machine:

Roll forming machine production process:

Load container: