CRNGO grain oriented electric rotor silicon steel sheet coil, metal belt motor transformer core pure grade 15-520mm

- $2.00 / 300 - 299999 kilograms

$0.60 / >=300000 kilograms - 300 kilograms

- Shanghai Lulu Technology Co., Ltd.

- Shanghai, China

- Ms Violet Zhuang

PRODUCT DETAIL

| port: | Ningbo, Shanghai | technology: | cold rolled |

| application: | engine | width: | 50-1250mm |

| Packaging Details: | Standard international heavy cargo packaging | tolerant: | ±1% |

| delivery time: | 15-21 days | standard: | GB, DIN, AiSi, ASTM, JIS |

| thickness: | 0.35mm, 0.5mm, 0.65mm | Surface treatment: | insulating paint |

| grade: | Silicon steel | port: | Shanghai, Ningbo port |

| Steel shape: | Coil | product name: | Non-oriented silicon steel |

| payment terms: | L/C, T/T | Surface treatment: | coating |

| Origin: | China | process: | cold rolled |

| Processing services: | bending, cutting | thickness: | 0.35 - 0.65mm |

| standard: | ASTM | Supply capacity: | 50000 tons per month |

| expiration of pay: | T/T or L/C | type: | Non-oriented silicon steel |

| Package preview: | shape: | steel coil |

Product Description

The difference between oriented silicon steel and non-oriented silicon steel

Non-oriented silicon steel: ferrosilicon alloy with extremely low carbon content. In the deformed annealed steel sheet, the grains are randomly distributed. The silicon content of the alloy is 1.5%-3.0%, or the sum of silicon and aluminum content is 1.8%-4.0%. The product is usually cold-rolled plate or strip and is mainly used in the manufacture of electric motors and generators.

Grain-oriented silicon steel: strong directionality, the lowest iron loss value in the rolling direction, and the highest magnetic properties

Magnetic permeability, under a certain magnetic field, has a higher magnetic induction value. The silicon content of grain-oriented silicon steel is about 3%. It also requires the steel to be low in oxide inclusions and must contain certain inhibitors (MnS, A1N)..

Non-oriented silicon steel: ferrosilicon alloy with extremely low carbon content. In the deformed annealed steel sheet, the grains are randomly distributed. The silicon content of the alloy is 1.5%-3.0%, or the sum of silicon and aluminum content is 1.8%-4.0%. The product is usually cold-rolled plate or strip and is mainly used in the manufacture of electric motors and generators.

Grain-oriented silicon steel: strong directionality, the lowest iron loss value in the rolling direction, and the highest magnetic properties

Magnetic permeability, under a certain magnetic field, has a higher magnetic induction value. The silicon content of grain-oriented silicon steel is about 3%. It also requires the steel to be low in oxide inclusions and must contain certain inhibitors (MnS, A1N)..

Product advantages

1. Stable performance

2. Excellent processing performance: high-precision size and excellent mechanical properties make it easy to be cut, stamped and stacked by high-speed punching machines. It also has good welding properties.

3. Excellent performance of insulating coating: uniform color, good insulation, high adhesion, good heat resistance,

Excellent processing performance

1. Stable performance

2. Excellent processing performance: high-precision size and excellent mechanical properties make it easy to be cut, stamped and stacked by high-speed punching machines. It also has good welding properties.

3. Excellent performance of insulating coating: uniform color, good insulation, high adhesion, good heat resistance,

Excellent processing performance

Specification

product name | Electrical steel, silicon steel, motor steel |

category | Oriented electrical steel; Non-oriented electrical steel |

standard | AISI, ASTM, DIN, GB, JIS, EN |

thickness | 0.35mm, 0.50mm, 0.65mm |

width | 50-1250mm |

grade | Yield strength (N/mm2) | Super tensile strength (N/mm2) | Ductility (%) | hardness |

M35W230 | 430 | 560 | 20 | 225 |

M35W250 | 415 | 550 | 20.5 | 220 |

M35W270 | 400 | 515 | 20.5 | 215 |

M35W300 | 360 | 480 | 21.5 | 195 |

M35W360 | 350 | 480 | 23.5 | 190 |

M35W440 | 275 | 420 | 27.5 | 165 |

M35W550 | 265 | 415 | 33.5 | 160 |

M50W250 | 430 | 560 | 19 | 230 |

M50W270 | 410 | 550 | 21.5 | 225 |

M50W290 | 395 | 545 | 22.5 | 220 |

M50W310 | 385 | 510 | 24.5 | 210 |

M50W350 | 350 | 475 | 26.5 | 190 |

M50W400 | 320 | 460 | 36 | 170 |

M50W470 | 295 | 425 | 35 | 160 |

M50W600 | 280 | 410 | 37 | 140 |

M50W800 | 285 | 405 | 38.5 | 135 |

M50W1300(D) | 250 | 360 | 40 | 115 |

insulating paint | ||||

coating type | M11 | M21 | ||

Element | Chromium-containing semi-organic coating | Chrome-free, semi-organic coating | ||

Coating thickness (μm) | 0.7~1.5 | 0.8~5.0 | ||

Interlayer resistance (Ω•mm2 /sheet) | ≥100 | ≥100 | ||

Adhesive properties | Class A or Class B | Class A or Class B | ||

Stamping performance | Excellent | Excellent | ||

Anti-rust performance | Excellent | Excellent | ||

heat resistance | 750°C annealing resistance, N2 protection, 2h | General annealing resistance | ||

Workshop

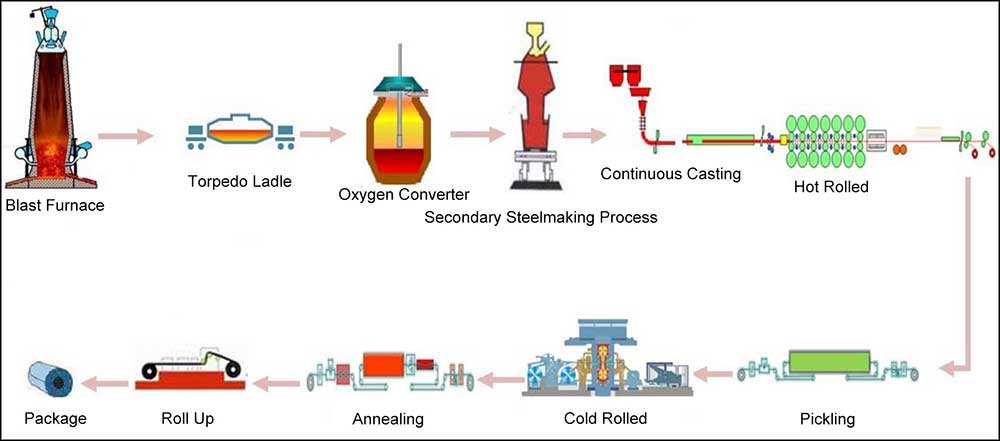

Manufacturing process

VIEW MORE

YOU MAY LIKE