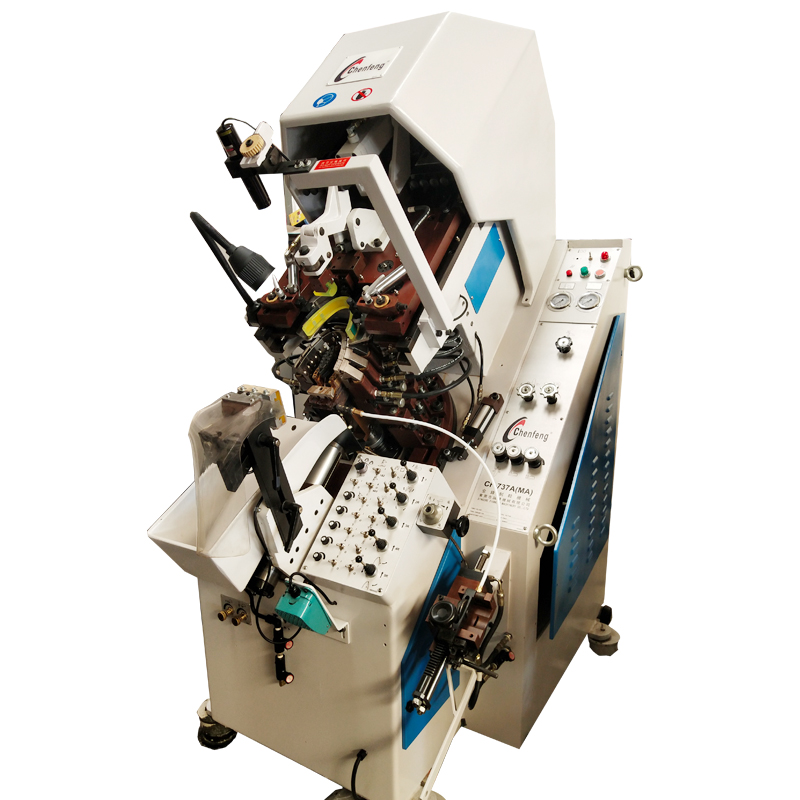

Chenfeng automatic glue toe cap lasting glue machine 9 clips CF737MA shoe making machine

- $6600.00 / 1 - 1 sets

$6000.00 / >=2 sets - 1 set

- Dongguan Yonghui Leather Machinery Co., Ltd.

- Guangdong, China

- Mr Li

| strength: | 2.2KW | Mechanical test report: | Not available |

| Warranty: | 3 months | Health status: | used |

| Production capacity: | 800p/d | Voltage: | 380/220V |

| Packaging Preview: | Core components: | motor | |

| type: | pneumatic | weight: | 1600 |

| Auto grade: | semi-automatic | Supply capacity: | 100 sets per month |

| port: | Shenzhen or Guangzhou | payment terms: | Western Union, T/T, MoneyGram |

| Video external inspection: | if | application: | Footwear industry |

| feature: | 9 pliers | After-sales service provided: | Provide overseas third-party support |

| Marketing Type: | normal product | place of origin; place of origin: | Taiwan, China |

| Applicable industries: | manufacturing plant | Function: | shoemaking |

| Showroom location: | not any | brand: | Morrowind |

| Dimensions (L*W*H): | 165*100*205cm | Packaging Details: | wooden base |

| Core Components Warranty: | 1 year | After Warranty Service: | Video technical support |

Hydraulic automatic toe gluer CF-738MA shoe making machine

Product Description

Taiwan original toe machine

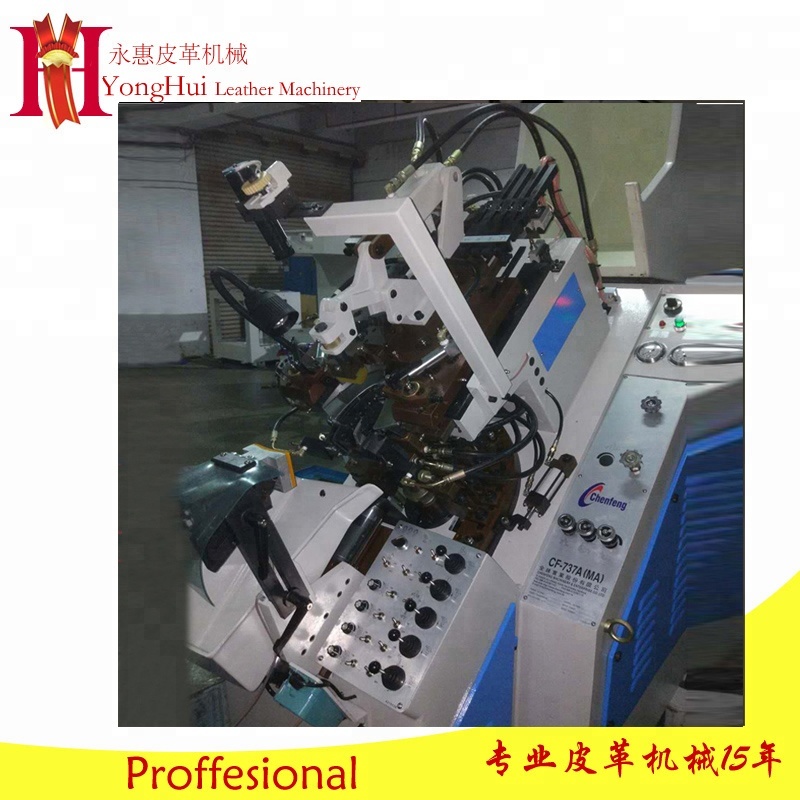

Model: CF-737A(MA)

Brand: Chen Feng

Widely used for long-lasting toe caps of all kinds of sports shoes

1. Computerized, can save 100 sets of shoe types

2. Automatic cementing

3. The middle clip opens quickly

4. The inner support rising speed is adjustable

5. Indenter floating adjustable

6. Full-function tensioner and wiper with special traces ensure that the vamp is close to the shoe last without any angle after bonding, which increases the appearance and improves the bonding quality.

7. The toe toe pressing mechanism adopts adjustable two-stage pressure, and the master-slave cylinder design makes the toe cap and wiper toe cap fit during the process, and the indenter is finally pressed, and the toe cap can be completed with one press. The process went smoothly. When positioned, it is less prone to extended lasting distances and front bumper pull-downs compared to soft leather materials

8. Each group of claws has an independent automatic pull-down function. According to the tightness of the upper, the desired claw can be selected for automatic pull-down action, and the pull-down depth can be adjusted if necessary

9. Nine claws are independently designed, which can be adapted to any form of Baotou Baotou. The principle of automatic balancing and automatic lowering when the wiper moves forward is also a feature to improve product quality and increase production.

10. The inner and outer brackets have two-stage ascending functions, which cooperate with the operation of the heel bracket to prevent the shoe last from sliding.

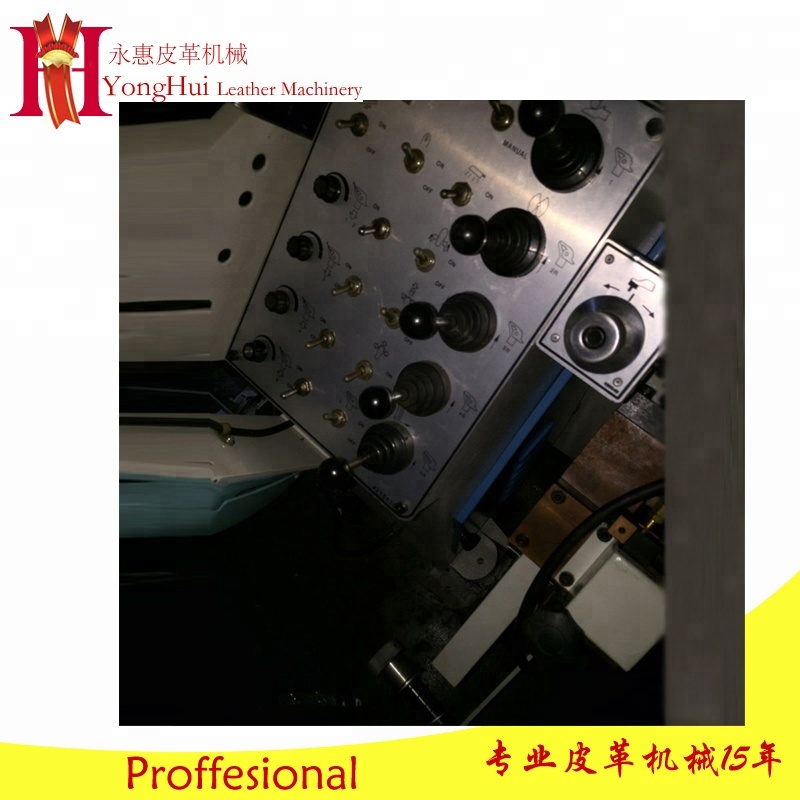

11. No tools required to adjust long-lasting action. It has scale and position rule indications.

12. Selection switches for various actions are necessary for operation and can be switched quickly

13. The auxiliary wiper is matched with the nine-claw toe cap to lengthen the toe cap length to the front center corner. After wrapping, the toe cap and upper can be more tightly fitted to the last

14. Automatic gluing function, durable.

15. Nine claws can adjust the pressure independently, and can be adjusted according to the tensile strength of the upper, which is not easy to damage the upper. The pressure of the whole machine can also be adjusted on the outer surface of the machine.

16. The claw plate has a two-stage adjustment function, and the two stages can be automatically switched according to the position of the shoe.

Packaging and Shipping

a. Standard wooden boxes will be used for packaging to ensure items will not be damaged.

b. Ships after order confirmation.

company information

Dongguan Yonghui Leather Machinery Co., Ltd. was established in 2005 and registered as a limited company in 2016. It is located in the world famous shoe manufacturing base - Houjie Town, Dongguan City, Guangdong Province, China.

We specialize in the production of various computerized sewing machines, refurbished Italian Atom

Leather cutting machines, as well as other brands such as Camoga and Fortuna leather machines, embossing machines and other related shoe-making machines. We have a professional production team, high-quality suppliers, experienced repair and refurbishment

staff. We have our own warehouse, covering an area of about 1200 square meters. we have a physics

The store covers an area of about 200 square meters. We provide high-quality machinery with reasonable prices and perfect after-sales service.

touch:

Dongguan Yonghui Leather Machinery Co., Ltd.

International Department:

feature:

1.Hydraulic operating system.

2. Each group of pliers can be set to automatically pull out or operate manually.

3. This machine is suitable for shoe uppers whose midsole is general, soft and whose heel is less than 180mm.

4.This machine is equipped with a constant height micro switch, which is easy to adjust and accurate in positioning.

We can provide all equipment for shoe factory. No matter what machine you want to make shoes, please contact us.

All machines are refurbished and in very good working condition

application:

shoe factory

Packaging and Shipping:

standard packaging

Dongguan Yonghui Leather Machinery Co., Ltd.Established in 2002 and registered as a limited company in 2016. It is located in the world famous shoe manufacturing base - Houjie Town, Dongguan City, Guangdong Province, China.

We mainly supply shoe making machines and bag making machines. We have our warehouse and sales team in China. Our warehouse covers an area of about 1200 square meters. We have a physical store that covers an area of about 200 square meters. Our main products are leather cutting machines, sewing machines and various shoe-making machines. We also represent new JUKI sewing machines and refurbished Italian Atom leather cutting machines, embossing machines, oil edge machines, scraping, splitting and hammer punching machines, with other brands such as Camoga and Fortuna leather machines, embossing machines and Other related shoe-making machinery. We can supply a complete set of machines for shoe factories and luggage and luggage manufacturers.

Our company has always adhered to the principle of "customer first, quality first, reputation first, service first"

Other Products

-

Dongguan efficient professional automatic eyelet punching machine$1049.00 / set

Dongguan efficient professional automatic eyelet punching machine$1049.00 / set -

Shoe making machine single head pneumatic single station manual sole pressing machine$338.00 - $371.00 / set

Shoe making machine single head pneumatic single station manual sole pressing machine$338.00 - $371.00 / set