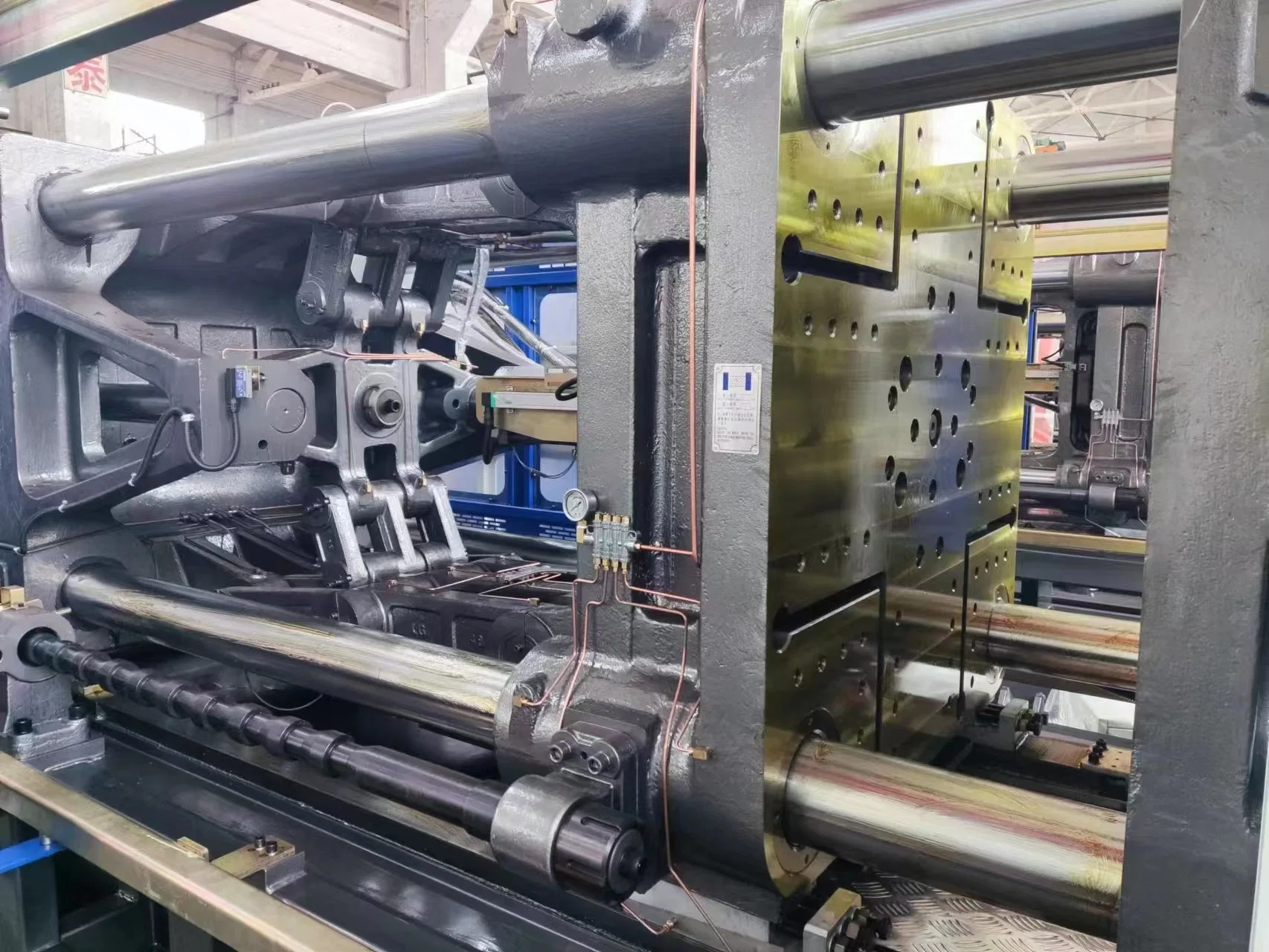

Fully automatic new horizontal PPR electric EPS polystyrene chair PC PVC PP PET preform plastic injection molding machine

- $15000.00 /set

- 1 set

- Taizhou Fupusi Machinery Co., Ltd.

- Zhejiang, China

- Mr John Tao

| Package preview: | Material: | PPR electric EPS polystyrene chair PC PVC PP PET | |

| structure: | Horizontal injection molding machine | Weight (kg): | 10000kg |

| application: | Thin wall packaging product production | Health status: | new |

| Tie rod spacing (width) (mm): | 820mm | Screw aspect ratio: | 18 |

| After-sales service provided: | Video technical support | Plastic processing: | PP, PC, ABS, PET, PVC, FRPP/PVC, PPR, EVA, HDPE, MLLDPE, EPS, PA, polystyrene, PE, LDPE, EVOH, HDPE/PP, ABS/PP, PE/PP, polylactic acid |

| Power (kW): | 4kW | Tie rod spacing (height) (mm): | 800mm |

| Video outbound inspection: | if | Plastic type: | ABS.AS.PS.HIPSPP.LDPE.HDPE.PMMD.PA6.POM.PCPVC.PET.PBT. Thermoplastic elastomer (PE) |

| product name: | Plastic injection molding machine | Core component warranty: | 1 year |

| Plasticizing capacity (g/s): | 600 | Packaging details: | Each machine in the container injection molding machine is well packaged and suitable for long-term transportation. |

| Screw speed (rpm): | 1 - 182 rpm | Key words: | PC.ABS.LCP.PP.PVC injection molding machine |

| Function: | Plastic injection molding machine | Supply capacity: | 300 sets per year |

| feature: | PET molding injection molding machine | Injection weight (grams): | 2580g |

| Applicable industries: | Hotels, clothing stores, building materials stores, manufacturing plants, machinery repair shops, food and beverage factories, farms, restaurants, household, retail, food stores, print shops, construction projects, energy and mining, food and beverage stores, advertising agencies, others | Core components: | Bearings, motors, pumps, gears, PLC, pressure vessels, engines, gearboxes, screws, others |

| brand: | Haiti | Place of origin: | Zhejiang, China |

| port: | Ningbo Port | Ejection force (kN): | 110kN |

| Showroom location: | not any | Injection rate (g/sec): | 536 g/s |

| Theoretical injection volume (cm3): | 3140 cubic centimeters | Type of machine: | Hybrid, hydraulic, electric, mechanical, other |

| payment terms: | Western Union, L/C, D/P, T/T | Main selling points: | Using servo motor, high speed, fully automatic, |

| Screw diameter (mm): | 85mm | Warranty: | 1 year |

| Opening stroke (mm): | 790mm | Used for: | PP PE PET plastic bottle preform second-hand molding machine |

| Distance between tie rods: | 110*110 | model: | N9856 |

| style: | horizontal | Mechanical test report: | not available |

| Ejection stroke (mm): | 200mm | type: | Pipe shoulder injection, preform injection, pipe head injection |

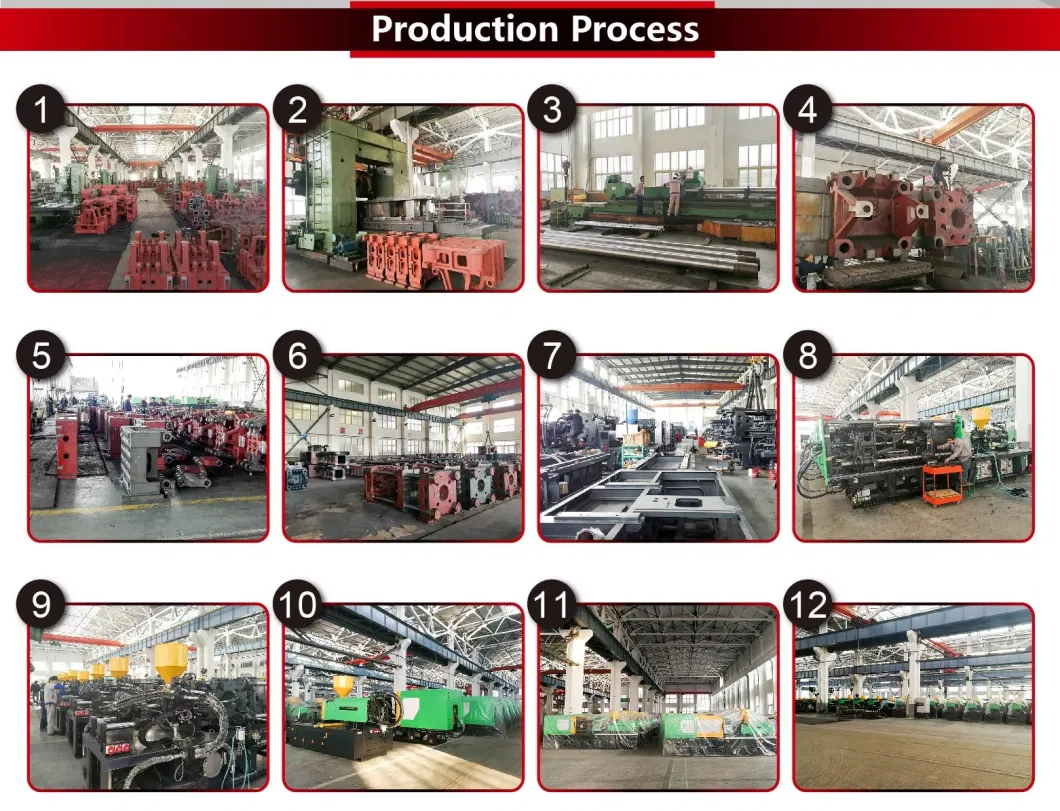

The supplier makes the following technical and after-sales service commitments

1) Provide English technical documents.

2) The machine is tested before delivery.

3) Provide technical support online services.

4) Reasonable prices when replacing consumables.

5) Spare parts are provided for every new machine

The equipment is implemented according to enterprise standards. The company has rich experience in the field of injection molding machines.

1) High torque oil motor pre-plasticizing drive

2) Five-fulcrum double crankshaft mold clamping

3) Oil motor drive gear adjustment mold

4) Automatic lubrication system

5) Accurate operation of pressure and flow

6) High quality oil pump

7) Injection multi-level pressure and speed adjustment

8) Chinese and English computer control

9) Mold group data memory function

This injection molding machine is well received by customers and has the following advantages:

1) Accuracy: Optimize the mechanical structure and adopt famous brand controllers to greatly improve machine accuracy.

|

Screw diameter |

mm |

60 |

65 |

70 |

|

Screw aspect ratio |

aspect ratio |

22.7 |

twenty one |

19.5 |

|

Injection weight |

Duke |

Chapter 772 |

905 |

10.5 |

|

Injection volume |

cubic centimeters |

Chapter 848 |

995 |

Chapter 1154 |

|

Injection pressure |

MPa |

207 |

176 |

152 |

|

Theoretical injection volume |

grams/second |

Chapter 241 |

Chapter 281 |

328 |

|

plastic capacity |

mm |

35.2 |

43.3 |

51.8 |

|

Injection stroke |

nanometer |

300 |

||

|

Screw torque |

RPM |

25300 |

||

|

Maximum screw speed |

Ton |

150 |

||

|

clamping force |

mm |

300 |

||

|

Mold height |

mm |

220-630 |

||

|

maximum daylight |

mm |

1220 |

||

|

Pushing force |

Ton |

7.06 |

||

|

Ejection stroke |

mm |

150 |

||

|

Number of injectors |

|

9 |

||

|

Oil pump motor |

kilowatt |

30 |

||

|

Pump pressure |

MPa |

16 |

||

|

heating power |

kilowatt |

twenty two |

||

|

Machine size |

rice |

6.2*1.6*2.1 |

||

|

Machine weight |

Ton |

11 |

||

|

Fuel tank capacity |

L |

Chapter 560 |

||

|

International designation |

|

3000-1750 |

||

2) Stable: dual-cylinder injection, stable and reliable performance.

3) Durable: The deck adopts DFA design to help strengthen rigidity

4) Energy saving: Compared with traditional fixed pumps or variable pumps, it saves energy significantly.

Servo motor control:

» The energy-saving effect is excellent. Compared with traditional fixed-pump injection molding machines, it saves 20%-80% of energy under the same working conditions.

» Excellent injection molding stability

" fast reaction

» Low noise and quiet operation

» Constant oil temperature

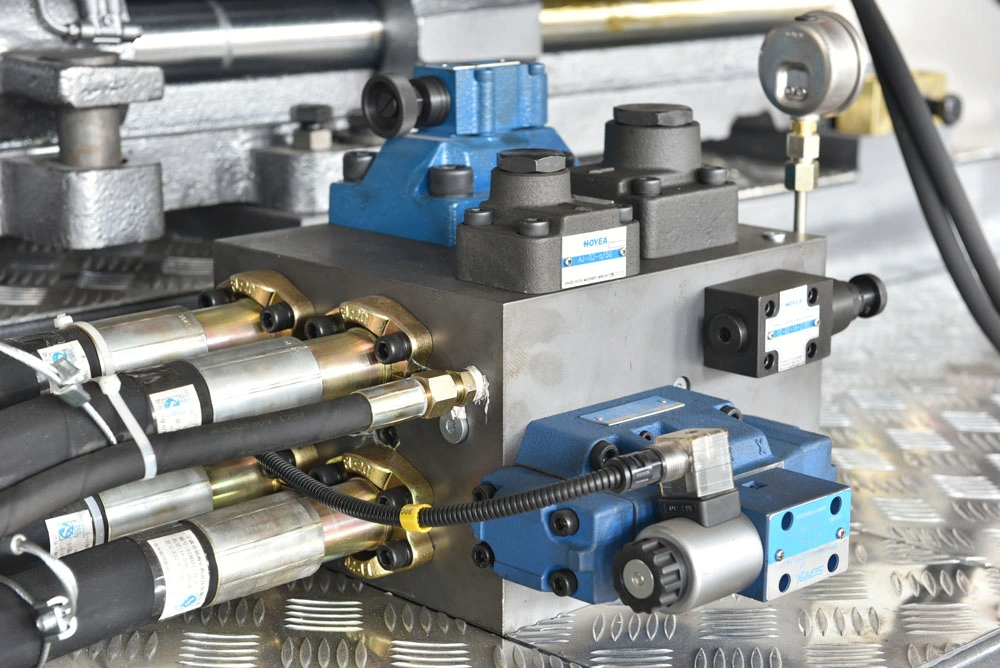

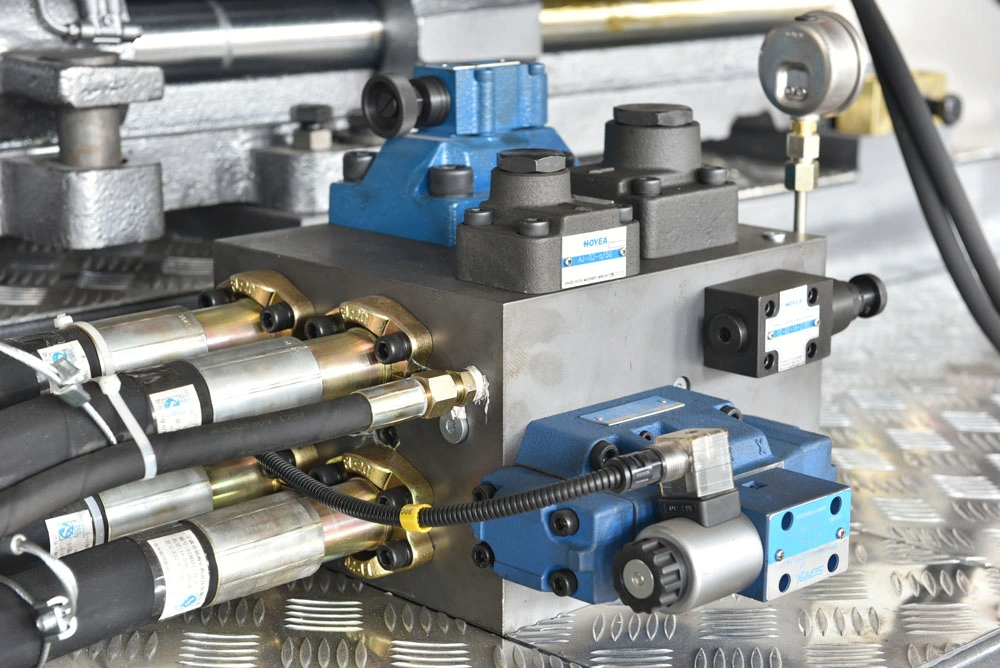

control:

» TFT LCD color display

» Using high-speed DSP processor, the time control accuracy reaches

» High-precision displacement sensor system for precise control

» Using fuzzy prediction technology, precise temperature control

» Multiple input/output interfaces, interface functions can be set as needed.

» With output programmable function

» Support USB and network interface (optional)

» Parameter data lock protection, with automatic saving function in case of unexpected power outage

» Big data storage capabilities

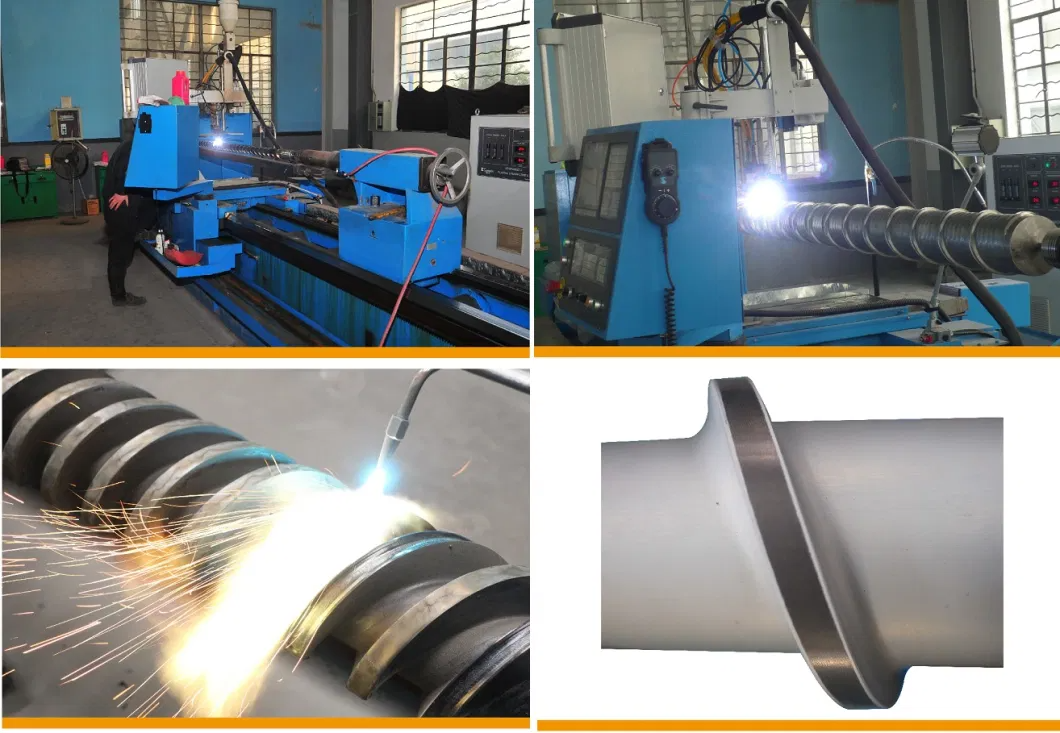

injection:

» The injection device is supported by double guide pillars and equipped with a fast and powerful double-cylinder balanced injection structure.

» Optimized design of screw group to achieve excellent plasticizing effect.

» Use high-quality nitrided alloy or chromium-plated screw and nitrided barrel.

Fully automatic new horizontal PPR electric EPS polystyrene chair PC PVC PP PET preform plastic injection molding machine

Automatic plastic injection molding machine for Haitian mini small pet PP preform vertical price chair manufacturing PVC

New horizontal ppr electric eps polystyrene pc molding plastic injection molding machine

Fully automatic new horizontal PPR electric EPS polystyrene chair PC PVC PP PET preform plastic injection molding machine

Second hand molding machine

feature:

» Injection slide linear guide reduces wear and ensures precise and stable injection control. (Elective)

» T-slot mold pressure plate

» Use internationally renowned brands of electrical and hydraulic components.

» The injection base is modular and different matching types can be selected according to the injection volume.

» Smooth mold opening speed curve design and increased speed command to reduce machine vibration.

» Excellent precision control, the finished product weight error is about 0.7% to 0.4%.

» Using servo energy-saving system can reduce energy consumption by 40%-70%.

clamp:

» Hydraulic (optional), mechanical and electric triple interlocking safety device, the mold cannot be closed when any safety door is opened.

» Low-pressure mold protection device protects the mold from damage by foreign objects.

» The hydraulic ejector pin is used to adjust the stroke, front and rear ejection pressure and speed to achieve a variety of actions.

» Use high-precision linear sensors for position detection, multi-region control of mold opening stroke speed and position, and accurate positioning.

» Strengthen the wear-resistant guide rail of the moving template.

» Centralized lubrication system ensures uniform oil supply to each lubrication point.

feature:

» Injection slide linear guide reduces wear and ensures precise and stable injection control. (Elective)

» T-slot mold pressure plate

» Use internationally renowned brands of electrical and hydraulic components.

» The injection base is modular and different matching types can be selected according to the injection volume.

» Smooth mold opening speed curve design and increased speed command to reduce machine vibration.

» Excellent precision control, the finished product weight error is about 0.7% to 0.4%.

» Using servo energy-saving system can reduce energy consumption by 40%-70%.