HSS DIN5482 Modulus Internal Tooth Spline Broach, PA30 Degree

- $35.00 / >=2 pieces

- 2 pieces

- Chongqing Yuqing Machine Tools Co., Ltd.

- Chongqing, China

- Ms Sabrina Tang

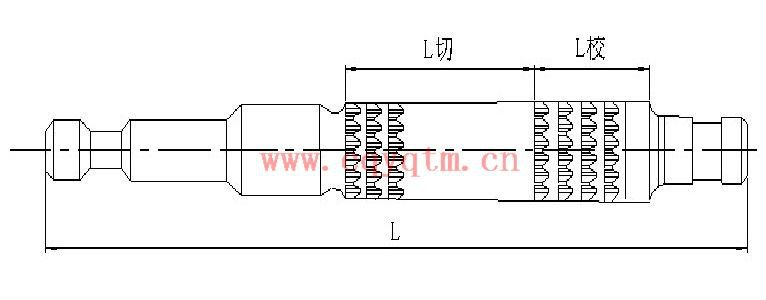

| Broaching length: | 10~120mm | Type of machine: | broaching bed |

| module: | m1~m5 | Packaging Details: | Internal involute spline broaches PA30 Packing: oiled + wooden box or as required |

| Shipping Details: | within 25 days | place of origin; place of origin: | Chongqing, China |

| Material: | M2/M35/M42 | Supply capacity: | 3000 pieces per month |

| payment terms: | L/C, D/P, T/T, Western Union, MoneyGram, PayPal | port: | Shenzhen |

| brand: | Q | standard: | DIN5482 |

| pressure angle: | 30/45 degrees | model: | custom made |

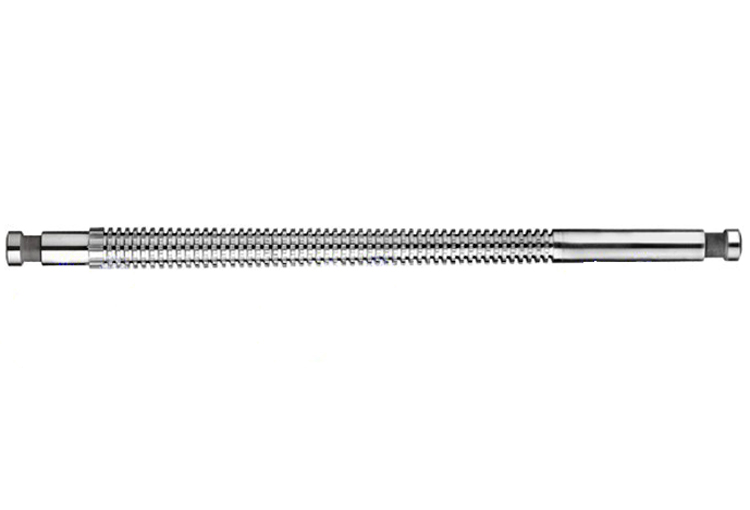

HSS DIN5482 modulus internal tooth spline broach PA30 degree internal tooth broach square broach

Specification table of internal spline broach:

module | Base slot width | Number of teeth | overall length | Broaching length |

1 | 1.571 | 12~40 years old | 430~1000 | 10~120 |

1.25 | 1.963 | 550~1120 | 18~120 | |

1.5 | 2.356 | 570~1140 | ||

2 | 3.142 | 650~1390 | ||

2.5 | 3.927 | 740~1600 | ||

3 | 4.712 | 12~30 | 820~1580 | |

3.5 | 5.498 | 12~26 years old | 850~1670 | |

4 | 6.283 | 12~22 | 920~1520 | |

5 | 7.854 | 12~18 years old | 1120~1620 |

notes:

1. Standard pressure angle 30° involute spline broaches

2. Fine-pitch involute spline broaches with m0.5~m0.8 base circle diameter ≥ 6mm can be customized

3. Standard PA45° involute serrated broaches, m0.5~m2.5 can also be customized.

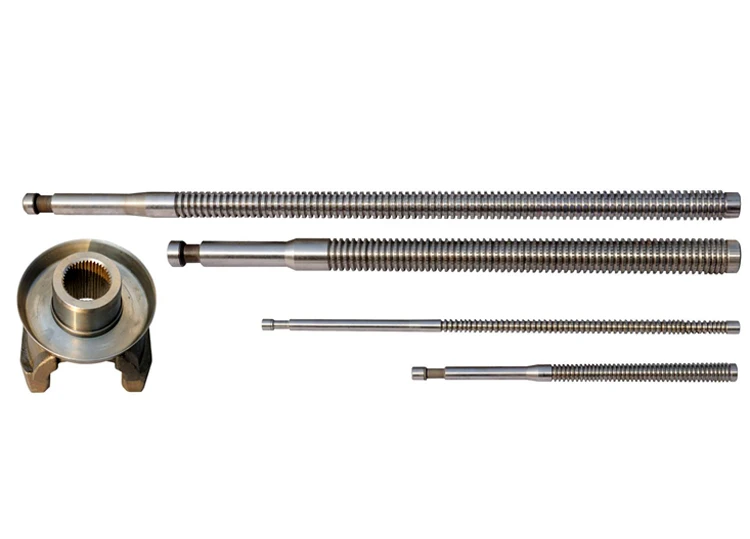

Broaches series: round broaches, parallel spline broaches, involute spline broaches, hexagonal broaches, square broaches, keyway broaches, triangular spline broaches, etc.

Material introduction:

A. W6Mo5Cr4V2 (national standard) M2 (ASTM), S6-5-2 (DIN), SKH51 (JIS)

Chemical composition: C 0.85, Si 0.38, Mn 0.35, P≤0.030, S≤0.030, Cr 4.10, W 6.00, Mo 4.80 V 1.85

Main application: Widely used to make various cutting tools and durable cold working molds

B. W6Mo5Cr4V2Co5 (national standard), M35 (ASTM), 1.3243 (DIN), SKH55 (JIS)

Chemical composition: C 0.93, Si 0.38, Mn 0.35, P≤0.030, S≤0.030, Cr 4.10, W 6.30, Mo 4.80 V 1.85, Co 5.00

Main application: Good wear resistance, often used to make high-speed, difficult-to-cut blades

W6Mo5Cr4V2(M2), W9Mo3Cr4V(W9), W18Cr4V(W18), W6Mo5Cr4V2Al(M2Al), W6Mo5Cr4V2Co5(M35), W2Mo9Cr4VCo8(M42), W4Mo3Cr4VSi(4341), W4Mo2Cr4VSi(4241)