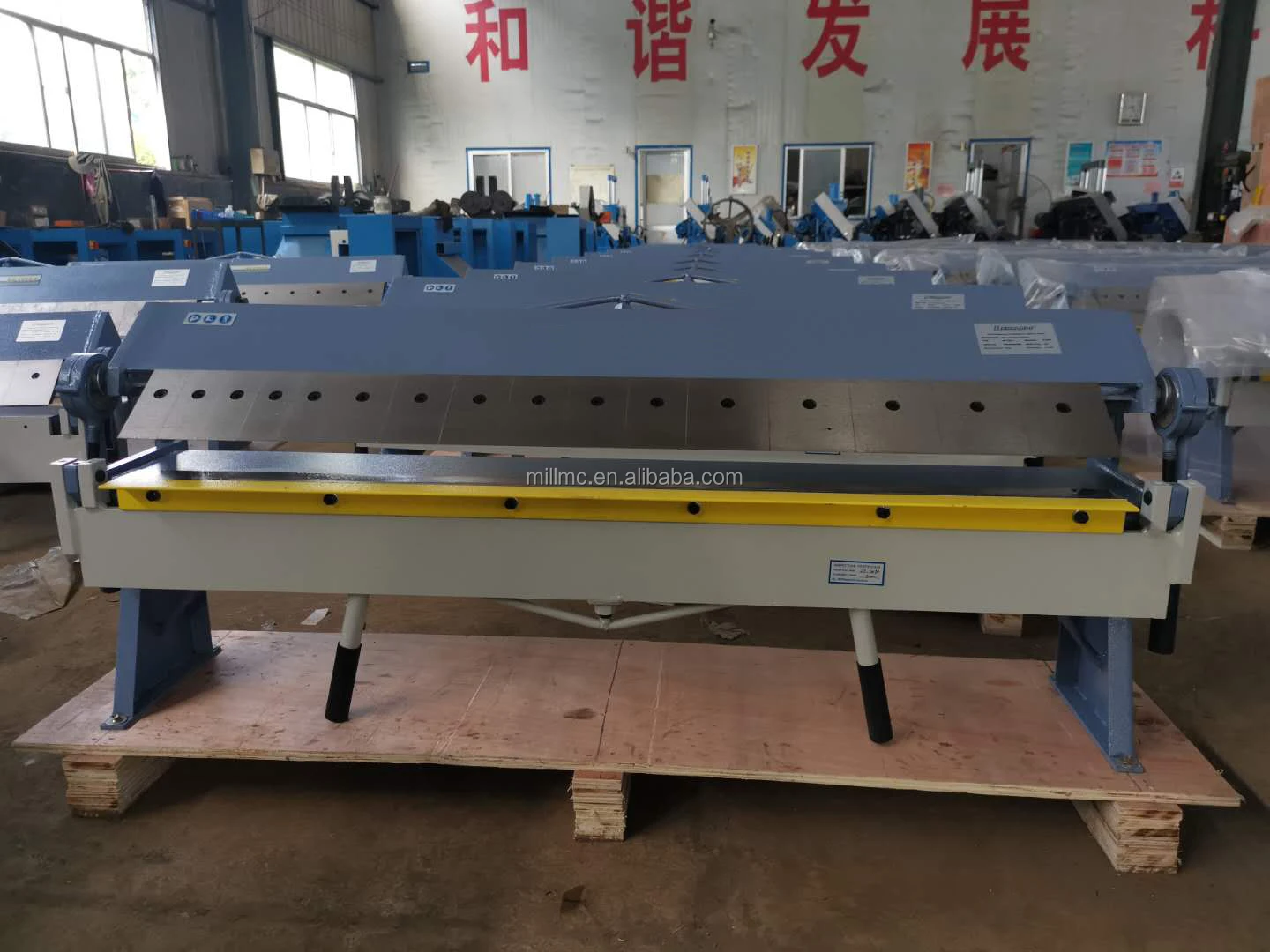

Hand Brake Manual Sheet Metal Bending Machine W2.0x2040/W2.5 Series

- $230.00 / 1 - 4 sets

$220.00 / 5 - 9 sets

$200.00 / >=10 sets - 1 set

- Shandong Miller Machine Tool Co., Ltd.

- Shandong, China

- Mr Jason Ma

PRODUCT DETAIL

| Motor Power (kw): | 0 kw; | Material / Metal Processed: | Brass / Copper,stainless steel,ALLOY,Carbon Steel,Aluminum,Plastic,PVC; |

| Payment Terms: | T/T,Western Union; | Nominal Pressure (kN): | 1300; |

| Port: | qingdao, shanghai; | Video outgoing-inspection: | Provided; |

| Place of Origin: | China; | Extra Services: | End Forming; |

| Throat Depth (mm): | 80; | After Warranty Service: | Video technical support,Online support,Spare parts,Field maintenance and repair service; |

| Control: | manual; | Package Preview: | ; |

| Weight (KG): | 770; | Condition: | New; |

| Applicable Industries: | Garment Shops,Building Material Shops,Machinery Repair Shops,Manufacturing Plant,Farms,Home Use,Retail,Construction works ,Energy & Mining; | Marketing Type: | Ordinary Product; |

| Machinery Test Report: | Provided; | Warranty: | 1 Year; |

| Packaging Detail: | PLYWOOD CASE; | Local Service Location: | None; |

| Automation: | Manual; | Warranty of core components: | 1 Year; |

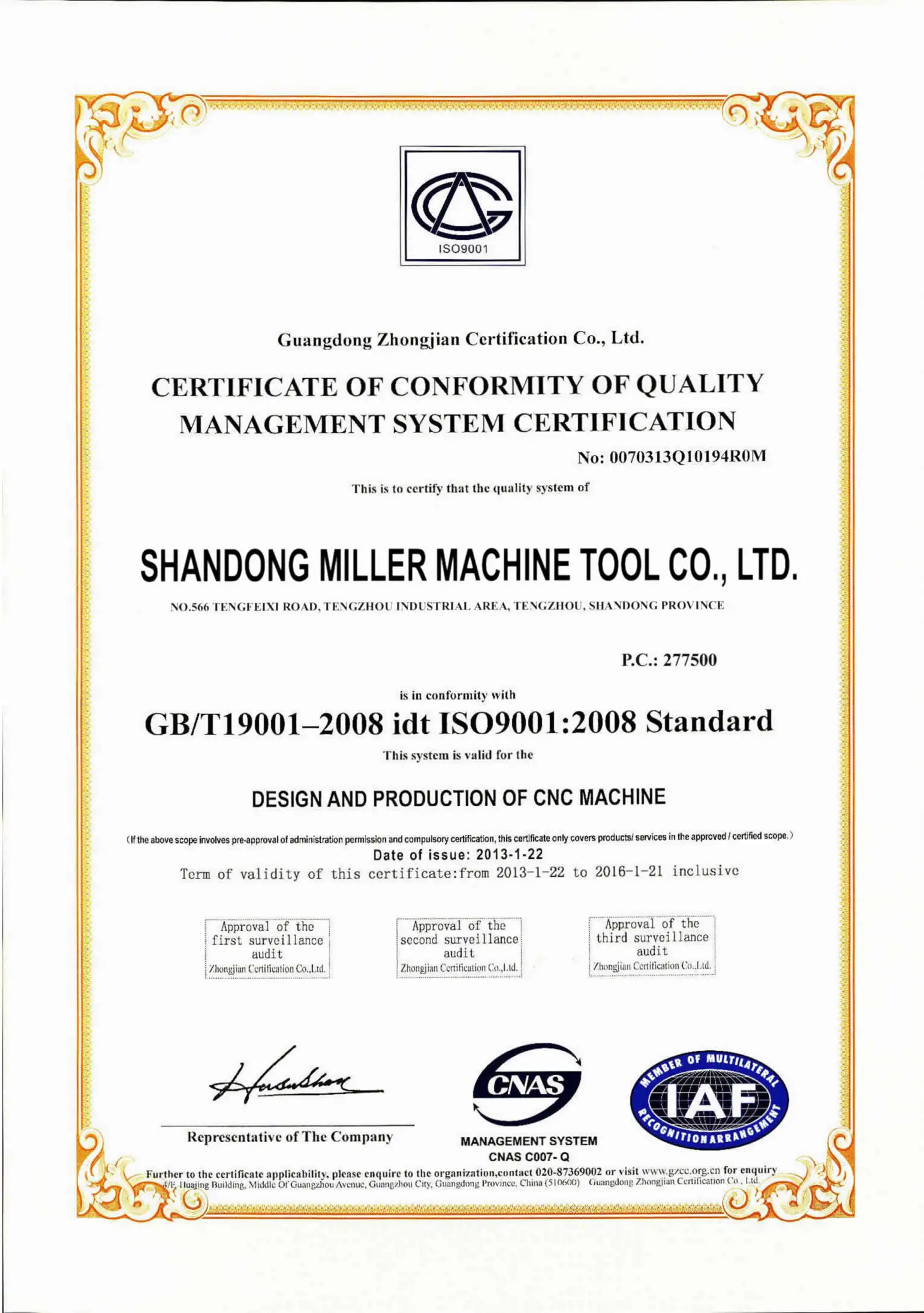

| Slider Stroke (mm): | 50; | Certification: | ce; |

| Color: | Customized; | Key Selling Points: | Competitive Price; |

| After-sales Service Provided: | Free spare parts,Field installation, commissioning and training,Field maintenance and repair service,Video technical support,Online support; | Length of Working Table (mm): | 2520; |

| Name: | plate pan and box brake; | Supply Ability: | 300 Set/Sets per Month; |

| Width of Working Table (mm): | 900; | Processing material: | Steel Alimunum alloy; |

| Material: | Aluminum Steel stainless steel; | Usage: | metal Sheet Folding; |

| Automatic Level: | Manual; | Showroom Location: | None; |

| Machine Type: | Torsion Bar; | Function: | metal sheet Bending; |

| Core Components: | Bearing,Gear,Gearbox; | Other name: | plate bending machine; |

Manual Press Brake Pan and Box Brake

Application:

1. used for processing thin plates.

2. The bending blade is a kind of folded box, featuring simple structure and easy operation.

3. Its maximum bending thickness is 1.0/1.2 mm.

4. With segment bending blade for the bending of box section.

5. Various widths segment shiftable setup.

6. With balanced hammer , it can easy to operate and easy for folding

Product Description

Model | Capacity (mm) | ||||||

Length | Thickness | Angle | |||||

W1.2X460 | 460 | 1.2 | 0-90° | 50X12X65 | 4.5/5 | ||

W1.2X760 | 760 | 1.2 | 0-90° | 90X17X12 | 14/15 | ||

W1.2X610 | 610 | 1.2 | 0-135° | 81X21X37 | 24/26 | ||

W1.2X1000 | 1000 | 1.2 | 0-135° | 124X26X18 | 33/35 | ||

W1.0X305 | 305 | 1.0 | 0-135° | 50X30X37 | 19/21 | ||

W1.0X610 | 610 | 1.0 | 0-135° | 81X30X35 | 28/31 | ||

W1.0X915 | 915 | 1.0 | 0-135° | 116X41X59 | 65/78 | ||

W1.2X1220 | 1220 | 1.2 | 0-135° | 158X39X58 | 90/104 | ||

W1.0X305A | 305 | 1.0 | 0-135° | 50X35X41 | 28/30 | ||

W1.0X610A | 610 | 1.0 | 0-135° | 81X35X42 | 43/46 | ||

W1.0X915A | 915 | 1.0 | 0-135° | 117X35X43 | 70/80 | ||

W1.5X1220 | 1220 | 1.2 | 0-135° | 161X48X68 | 135/151 | ||

W1.5X1260A | 1260 | 1.5 | 0-135° | 161X48X68 | 133/151 | ||

W1.2X1500 | 1500 | 1.2 | 0-140° | 200X76X125 | 285/355 | ||

W1.0X2000 | 2000 | 1.0 | 0-140° | 250X76X125 | 410/500 | ||

W1.0X1260 | 1260 | 1.0 | 0-140° | 158X39X58 | 94/108 | ||

W2.5X1220 | 1220 | 2.5 | 0-135° | 175X77X90 | 520/580 | ||

W2.0X2040A | 2040 | 2.0 | 0-135° | 250X77X110 | 850/1000 | ||

W2.5X2040A | 2040 | 2.5 | 0-135° | 250X77X110 | 1145/1295 | ||

W2.0X2540A | 2540 | 2.0 | 0-135° | 300X79X120 | 1190/1360 | ||

W2.5X2540A | 2540 | 2.5 | 0-135° | 300X77X110 | 1310/1480 | ||

W2.0X3050A | 3050 | 2.0 | 0-135° | 350X77X110 | 1490/1690 | ||

Recommend Products

Company Introduction

Company Overview:

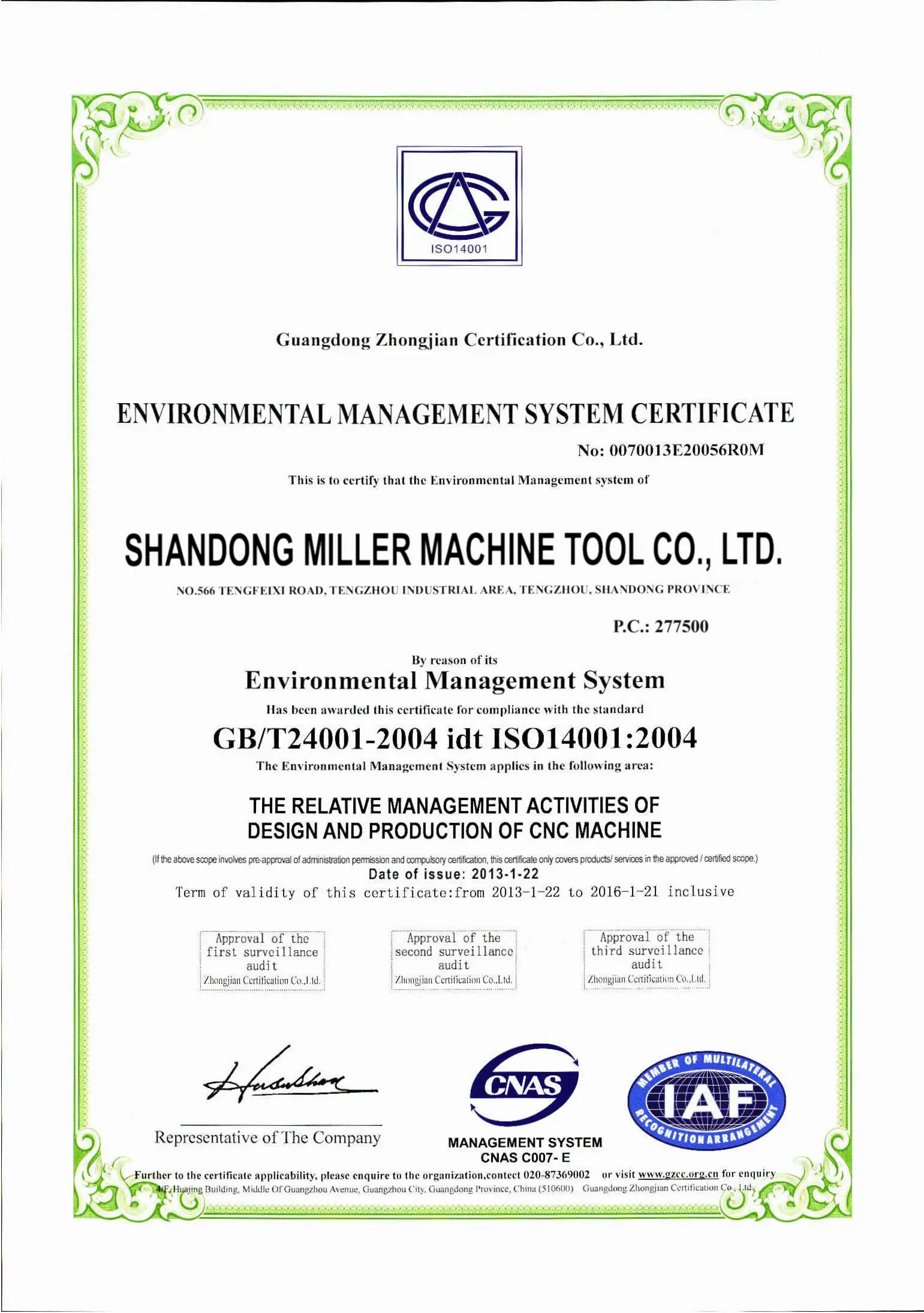

Shandong Miller Machine Tool Co., Ltd. is Specialized in the produing of various types of machine tools, which is built in 2010 year, and located in Tengzhou city, Shandong province. The company covers an area of 100,000 square meters and has over 100 workers, 10 Technical R & D workes, 5 Quality control Workers. The company's annual production value over 10 Million US Dollars.

Company Main production:

Shandong Miller Machine Tool Co., Ltd. main products are: CNC Vertical Machining Center, Cnc Milling Machine, Cnc Lathe, Conventional Lathe, Milling Machine, Drilling Machine, Planer etc.

Company Culture:

Company Target: Provide the best products at the best price

Company Idea: Customers are our God, quality is God's request

Customer Photos

Our Advantages

Products Advantages:

Our company has over 10 years producing history, with professional technical team and quality control team.

Our factory has 5 work shops with over 300 sets all kinds of machines, and has over 300 workers.

Production process is strictly in accordance with the production process, ensure that each machine is qualified before delivery.

Service advantages:

Pre-sale service:

1. Provide Lathes technical consulting services to customers free of charge.

2. Provide the company with the company profile and credit certificate.

3. Invite customers to visit our company to inspect the manufacturing process.

In Producing service

Customers can come to our company to know the progress of production at any time.

After-sale service

1. Our company can dispatch technicians to carry out on-site installation and commissioning according to customer requirements.

2. Customers can send employees to our company for acceptance and training.

3. The warranty period of our company's lathe machine is ONE year. During the warranty period, our company provides damaged parts for customers free of charge, and dispatches technicians to solve problems on the spot according to customer requirements.

4. Our company promises to respond to customer questions in a timely manner after receiving feedback of qualit, and provide solutions within 24 hours.

Certifications

FAQ

Q1. How can I get a quotation?

A1. Leave us massage with your purchase requements and we will reply you ASAP. And you may contact us directly by Whatsapp / Phone:+86-18063203806 or Telephone.

Q2. Can you provide customized machine or SPM (Special purpose machine)?

A2. Yes, we provide smart CNC solutions for our customer, in order to increase efficiency.

Q3. Can you provide training for operation CNC machines?

A3. Yes, free training in our factory is available.

Q4. What's your warranty terms?

A4.We will supply a replacement for parts that prove to be defective for a period of one year.

Extended warranty is available at the time of purchase.

Q5. What’s the delivery time, and what’s the package?

A5. Normally the delivery time is about 30-45 days. All our CNC machines are packed with PLYWOOD package.

VIEW MORE