High quality organic waste compost cat litter compound fertilizer pan compactor granulator extruder price

- $900.00 /set

- 1 set

- Henan Shunzhi Machinery Co., Ltd.

- Henan, China

- Ms Vivian Lei

PRODUCT DETAIL

| motor: | 11KW | Core Components Warranty: | 1 year |

| place of origin; place of origin: | Henan, China | Output (kg/hour): | 300 |

| Video external inspection: | if | color: | client needs |

| Health status: | new | Warranty: | 1 year |

| product name: | fertilizer disc disc compaction granulator extruder price | Marketing Type: | New Products 2020 |

| payment terms: | L/C,Western Union,D/P,D/A,T/T | Power (kW): | 1.5 |

| Main selling point: | energy saving | Showroom location: | not any |

| Function: | Production of organic fertilizer pellets | Packaging Details: | Packaging and Shipping 1) All worn spare parts are packed in plastic film and wooden boxes. 2) Wire and cable are used to fix the machine. 3) FCL: Standard export container shipping. 4) LCL: poly-wooden boxes. |

| Supply capacity: | 500 sets per month | Applicable industries: | Farm, chemical and mechanical equipment |

| Weight (kg): | 210 | Type of machine: | granulator, granulator |

| Voltage: | 220/380v | Advantage: | energy-saving consumption |

| Core components: | motor | Mechanical test report: | if |

| Dimensions (L*W*H): | 1200*950*1300mm | application: | Fertilizer Granulator |

| Packaging Preview: | Name: | Disc granulator | |

| Model: | SZ-800 | port: | Qingdao, Tianjin, Shanghai, Guangzhou, or upon request |

| work method: | wet process | brand: | Shunzhi |

| Product Category: | fertilizer |

Disc granulator

Disc granulator is a type of granulator. The disc of the disc granulator is lined with high-strength FRP, which has the advantages of uniform granulation, high granulation rate, stable operation, durable equipment, and long service life. Very ideal pelletizing equipment. The granulation disc adopts an overall arc structure, and the granulation rate can reach more than 93%. The pelletizing pan is equipped with three discharge openings, which facilitates intermittent production operations. The reducer and motor are driven by flexible belts, which can start smoothly and reduce the impact force. The bottom of the granulation pan is reinforced with multiple radiant steel plates, which are durable and never deformed.

The disc granulator is composed of a large plate, a large gear, a transmission part, a frame, a base, a scraper frame, and an unpowered scraper.①The main body of the disc granulator, the main body includes the frame structure, the adjustment part and the granulation disc; ②One main reducer, the input shaft is equipped with a pulley, and the output shaft is equipped with a pinion; ③One pulley main point motor; ④ Matching Pelletizing disc device, including a main shaft, two roller bearings, and two bearing seats;

Working principle of disc granulator

Various dry powder materials are added from the top of the equipment, degassed and pre-pressed by a screw, and then conveyed to the arc-shaped notch of the two rollers. The two drums rotate at the same speed and in opposite directions, biting the material into the tank and forcibly compressing it. After passing through the compression zone, the pressure gradually decreases, and its surface tension and gravity make it escape naturally, enter the crusher and classifier for crushing and dressing, and then enter the vibrating screen for screening, and the qualified products are sent out through the conveyor warehouse or directly packaged into finished products .

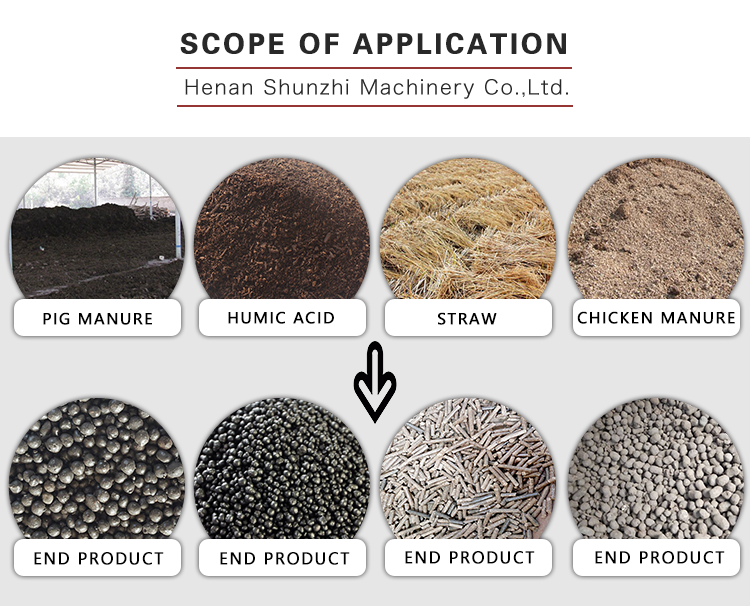

Disc granulator

The disc granulator is suitable for conveying various powder, material or small block non-stick materials, such as organic fertilizer, animal manure, coal powder, cement, clinker, limestone, shale, coal gangue, clay, etc. Used in gold concentrators, coal mines, chemicals, infrastructure and mechanized foundries, etc., as equipment for continuous, uniform, dosing and batching.

Model | Disc diameter (mm) | side height (mm) | Rotating speed (rev/min) | Motor Power (kilowatt) | capacity (tons/hour) | Reducer model | Dimensions (mm) |

SZ-500 | 500 | 200 | 32 | 0.55 | 0.02-0.05 | BWY0-43-0.55 | 650*600*800 |

SZ-600 | 600 | 280 | 33.5 | 0.75 | 0.05-0.1 | BWY0-43-0.55 | 800*700*950 |

SZ-800 | 800 | 200 | twenty one | 1.5 | 0.1-0.2 | XWD4-71-1.5 | 900*1000*1100 |

SZ-1000 | 1000 | 250 | twenty one | 1.5 | 0.2-0.3 | XWD4-71-1.5 | 1200*950*1300 |

SZ-1200 | 1200 | 250 | twenty one | 1.5 | 0.3-0.5 | XWD4-71-1.5 | 1200*1470*1700 |

SZ-1500 | 1500 | 300 | twenty one | 3 | 0.5-0.8 | XWD5-71-3 | 1760*1500*1950 |

SZ-1800 | 1800 | 300 | twenty one | 3 | 0.8-1.2 | XWD5-71-3 | 2060*1700*2130 |

SZ-2000 | 2000 | 350 | twenty one | 4 | 1.2-1.5 | XWD5-71-4 | 2260*1650*2250 |

SZ-2500 | 2500 | 450 | 14 | 7.5 | 1.5-2.0 | ZQ350 | 2900*2000*2750 |

SZ-2800 | 2800 | 450 | 14 | 11 | 2-3 | ZQ350 | 3200*2200*3000 |

SZ-3000 | 3000 | 450 | 14 | 11 | 2-4 | ZQ350 | 3400*2400*3100 |

SZ-3600 | 3600 | 450 | 13 | 18.5 | 4-6 | ZQ400 | 4100*2900*3800 |

pre-sale service:

1. Provide comprehensive technical and business consulting services;

2. Propose the most suitable solutions and equipment for customers;

3. According to the special requirements of customers, design and manufacture target products;

4. Regularly train high-quality maintenance technicians;

5. Free CAD design: If you can provide materials, your target capability and your factory information, we can design CAD for you for free.

2. Fast and safe delivery;

3. Assist customers in equipment infrastructure construction;

4. Send engineers to install and debug equipment;

5. On-site training of front-line operators;

6. Regularly visit customers to solve production problems and provide lifelong maintenance services

7. Provide technical exchanges.

2. Propose the most suitable solutions and equipment for customers;

3. According to the special requirements of customers, design and manufacture target products;

4. Regularly train high-quality maintenance technicians;

5. Free CAD design: If you can provide materials, your target capability and your factory information, we can design CAD for you for free.

After-sale service:

1. The equipment is highly inspected in each process, and the quality is the first;2. Fast and safe delivery;

3. Assist customers in equipment infrastructure construction;

4. Send engineers to install and debug equipment;

5. On-site training of front-line operators;

6. Regularly visit customers to solve production problems and provide lifelong maintenance services

7. Provide technical exchanges.

Q1. Are you a factory or a trading company?

A1. We are a manufacturer and we also provide trade services.Q2. What about your price?

A2. We always supply products at low prices because we believe this is the way to build a long-term business and earn a good reputation. Our price is 3%-5% lower than the market average price.

Q3. What payment terms do you accept?

A3. Welcome customers to place orders through Alibaba Commercial Insurance! Other payment methods such as T/T, L/C, D/P, etc. can be negotiated.

Q4. How is your delivery time?

A4: Generally, it will take 15-20 working days after receiving your advance payment. The exact delivery time depends on the item and quantity you ordered.

Q5: What should I do if the machine is broken?

A5: The product warranty period is one year. When the machine fails, we will immediately provide you with technical advice and solutions. For those wearing parts, we guarantee a long-term supply of high-quality parts.

Q6: How do you keep our business in a good long-term relationship?

A6: 1. We maintain good quality and competitive price to ensure our customers benefit;

2. We respect every customer and regard them as friends, no matter where they come from, we sincerely do business with them and make friends.

VIEW MORE

YOU MAY LIKE