New Disc Stack Centrifuge with Self-cleaning Bowl from Chinese leading manufacturer since 1954

- $10000.00 /set

- 1 set

- Yixing Huading Machinery Co., Ltd.

- Jiangsu, China

- Mr Chouse Hu

| Voltage: | 220 - 480 V; | Packaging Detail: | standard seaworthy packing; |

| Motor: | ABB; | Package Preview: | ; |

| HMI: | SIEMNES; | Single gross weight: | 66.0 KG; |

| Key Selling Points: | Competitive Price; | Single package size: | 20X20X80 cm; |

| Warranty: | 1 Year; | After Warranty Service: | Video technical support,Online support,Spare parts,Field maintenance and repair service; |

| Place of Origin: | Jiangsu China; | Selling Units: | Single item; |

| Power: | 4 - 300 Kw; | Applicable Industries: | Food & Beverage Factory,Energy & Mining; |

| PLC: | SIEMENS; | Inverter: | ABB; |

| Condition: | New; | Weight: | 2000 kg; |

| Certification: | CE; | Showroom Location: | United Kingdom,United States,France,Germany; |

| Type: | Centrifuge; | After-sales Service Provided: | Free spare parts,Field installation, commissioning and training,Field maintenance and repair service,Video technical support,Online support; |

| Bearing: | SKF; | Brand Name: | HUADING; |

| Dimension(L*W*H): | 1600X1200X1700; | Local Service Location: | United Kingdom,United States,France,Germany; |

| Product Type: | Soap; |

Huading Separator has been at the forefront in the field of disc stack centrifuge separation technology for more than 50 years – which is why disc stack centrifuges from Huading Separator perform this crucial separation function exceptionally well.

Today, Huading Separator is the leader in mechanical separating technology in China. Huading developments are used in a wide range of areas – in the beverage and dairy industries, in recovering and processing oils and fats, as well as in chemicals, pharmaceuticals, biotechnology and starch technology. Other applications include marine engineering, energy, oil fields and industry.

this series disc stack centrifuge is specilized for liquid-liquid-solids separation. they are widely used in the field of food, beverage, chemical, pharm, energy.

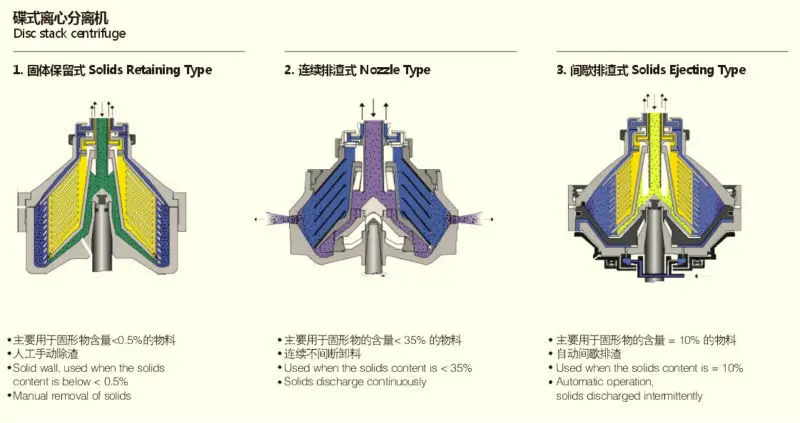

the disc centrifuge separates solids and one or two liquid phases from each other in one single continuous process, using extremely high centrifugal forces. When the denser solids are subjected to such forces, they are forced outwards against the rotating bowl wall, while the less dense liquid phases form concentric inner layers. The area where these two different liquid phases meet is called the interface position. This can be easily varied in order to ensure that the separation takes place with maximum efficiency. Inserting special plates (the “disc stack”) provides additional surface settling area, which contributes to speeding up the separation process dramatically. It is the particular configuration, shape and design of these plates that make it possible for a disc stack centrifuge to undertake the continuous separation of a wide range of different solids from either one or two liquids. The concentrated solids phase formed by the particles can be removed continuously, intermittently or manually, depending on centrifuge type and the amount of solids involved in the specific application.

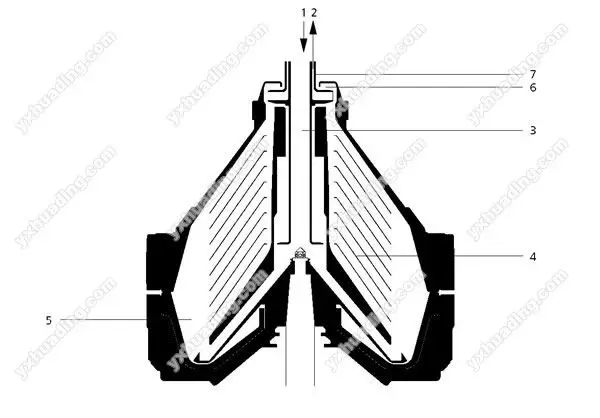

2-phase separation disc stack centrifuge separator

1 Feed

2 Discharge

3 Inlet tube

4 Disc stack

5 Solids holding space

6 Centripetal pump chamber

7 Centripetal pump

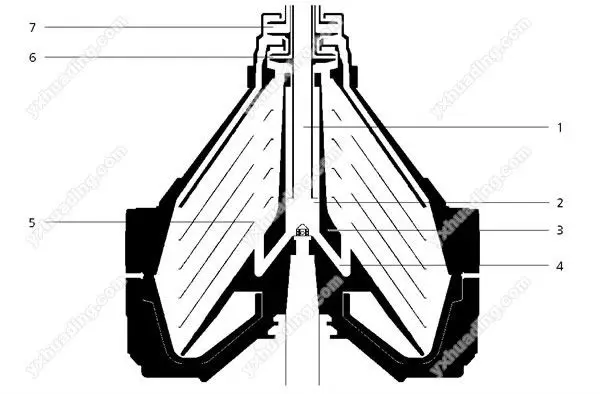

3-phase separation disc stack centrifuge separator

1 Inlet tube

2 Central bore

3 Distributor

4 Distributor bore

5 Rising channels

6 light phase centripetal pump

7 heavy phase centripetal pump

Usually, self-cleaning disc stack centrifuge separator is divided into two types. One is used for solids and two liquid phases from each other in one single continuous process, it is so called purifier. The other is used for solids and one liquid phase from each other, it is so called clarifier.