Orbital welding head automatic steel pipe welding machine full position pipe welding machine

- $10800.00 / 1 - 999 sets

$3240.00 / >=1000 sets - 1 set

- Wincoo Engineering Co., Ltd.

- Jiangsu, China

- Mr Jackie Nie

PRODUCT DETAIL

| Weight (kg): | 6.5 kg | product name: | Pipe Orbital Welding Machine |

| brand: | win cool | port: | Shanghai |

| weight: | 6.5 | usage: | pipe welding |

| Material: | CS, SS, etc. | Marketing Type: | normal product |

| Health status: | new | Packaging Details: | export package |

| Package preview: | strength: | 4500 | |

| payment terms: | L/C, D/P, D/P, T/T | Core component warranty: | 1 year |

| Protective gas: | Argon | color: | custom color |

| Warranty: | 1 year | Showroom location: | not any |

| Video shipment inspection: | if | Supply capacity: | 500 sets per month |

| Tube Thickness: | 0.5~3 mm | Origin: | Jiangsu, China |

| Welding tongs speed: | 0.15~4.5rpm | Applicable industries: | factory, construction |

| Main selling points: | low maintenance cost | Voltage: | AC220V±10% |

| Tungsten pole diameter: | 1.6~2.4 mm | Core components: | engine |

| aspect: | custom made | Diameter: | 6.35~114.3 mm |

| Welding method: | TIG orbital welding | Power (kW): | 4.5 |

| Mechanical test report: | if |

Product overview

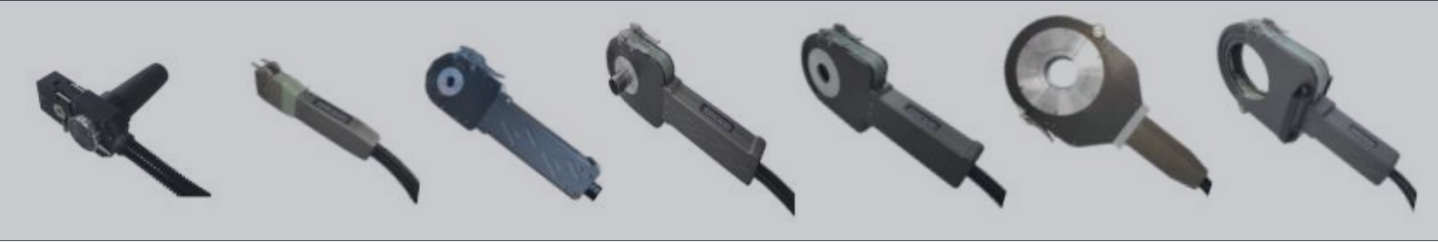

1. Closed pipe welding torch

This welding torch is a special welding torch designed and developed for all-position automatic welding of various pipe fittings.

two. Control Power Overview

XD-20W digital program-controlled welding power supply is composed of control system, power supply system and cooling water tank. It has the characteristics of digitalization, easy operation and reliability. The control system adopts an open and upgradeable operating system to centrally set, store and synchronize all-position welding function parameters. This power supply is specially designed and manufactured for thin-walled pipe/pipe welding. Mainly used in semiconductor, chemical, food, medicine, electronic assembly line and other industries, the overall design tends to be convenient, energy-saving, intelligent, and human-computer interaction. The volume and weight are reduced by one-third compared with the original split type. The integrated design is oriented to the small space construction on site.

Technical Parameters

1. Closed pipe welding torch | ||||||

1. Technical parameters | ||||||

Model | Cedar 40 | Western Electric 80 | Cedar 120 | |||

Main distribution | XD-20W full range programmable power supply | |||||

Main weldable materials | Carbon steel, stainless steel, titanium alloy, etc. | |||||

Welded pipe diameter range (mm) | 6.35-38.1 | 19.05-76.2 | 38.1-114.3 | |||

Maximum wall thickness (mm) | 2.5 | 3 | ||||

Torch Cooling | water cooling | |||||

Welding torch speed(rpm) | 0.3~6.0 | 0.2~5.3 | 0.1~3.8 | |||

welding shielding gas | Argon | |||||

Weight (kg) | 3.5 | 5 | 6.5 | |||

Dimensions (mm) | 377x129x42 | 438x155x44 | 540x195x54 | |||

B.Technical conditions | ||||||

Welded pipe diameter | Φ6.35mm-Φ114.3mm | |||||

Tube Thickness | 0.5-3mm | |||||

Tungsten Diameter | Φ1.6mm-Φ2.4mm | |||||

Welding tongs speed | 0.15rpm-4.5rpm | |||||

pipe | Carbon steel, stainless steel, titanium alloy, etc. | |||||

Welding method | Rotary non-winding all-position welding method, with automatic reset function | |||||

Welded pipe fitting form | Butt joints of straight pipes, tees, elbows, chucks, reducers, etc., no groove, self-fusion welding | |||||

Protective gas | Argon | |||||

cooling water flow | 1000ml/min | |||||

When welding carbon steel pipes, the 5-8mm of the solder joints should be polished to remove rust, exposing the original color of the metal | ||||||

The cut of the pipe should be flat, vertical and free of burrs, and there should be no gap between the two pipes | ||||||

Clean oil stains with acetone or alcohol | ||||||

The handle of the welding tongs is equipped with operation buttons, which is convenient for personnel to operate and improves work efficiency | ||||||

When welding the nozzle, the length of the straight line that can be clamped should not be less than 20mm | ||||||

Draw a circle with the center of the welded pipe fitting as the center, R=80mm, and there are no obstacles within the range | ||||||

two. Control Power Overview | ||

Model | XD-20W | |

temporary load rate | 200A 60% /155A 100% | |

Welding current | 5-200A | |

no-load voltage | 65V | |

Input voltage | AC220V±10% 50Hz/60Hz | |

strength | 4.5 kVA | |

torch cooling | Built-in circulating water cooling | |

exhibit | 10 inch touch screen | |

stored program | 99 | |

partitionable interval | 12 | |

Insulation class/Protection class | Protection class/IP21 | |

control function | DC/pulse current control, gas control, rotary motion, automatic/manual printing control, water cooling control | |

Protective function | Overvoltage, overload, leakage, arc failure and tungsten needle short circuit protection, missing parts detection | |

tank capacity | 4L | |

weight | 33KG (including 4L cooling water) | |

Product advantages

1. Closed pipe welding torch

1. The motor adopts German planetary motor

2. The inner wall of the welding torch adopts a water-cooling design to increase the duty cycle of the welding torch, so that the welding torch does not heat up when it works for a long time.

3. The core of the welding gun is made of imported materials and aluminum, which is light in weight and high in reliability.

4. The elastic patented clamp reduces the requirements for pipe fittings.

5. The special shape of the leakage hole can effectively ensure the beautiful appearance of the weld seam.

6. Spring self-locking mechanism, convenient and firm to replace the fixture.

7. Operation keys of welding torch handle: forward rotation, reverse rotation, emergency stop, attenuation, start, indicator light

two. Control Power Overview

1. 10-inch color screen, reasonable graphic design, and the machine conforms to ergonomic operating habits

2. Siemens PLC control system ensures fast, accurate and reliable operation of welding process parameters. Low maintenance costs.

3. Double cooling system greatly improves the duty cycle of the welding torch

4. Years of welding data accumulation, big data summary can be called directly

5. Welding real-time monitoring, graphic design directly in the operation interface, simple and direct

6. Light weight, easy to work at heights

7. The welding torch design is our exclusive patented technology, and the welding quality is guaranteed

8. With one-button printing and automatic printing functions, built-in mini maintenance-free printer

9. The core components are imported from Germany, which can guarantee the stability of the equipment to a large extent

construction site photos

VIEW MORE