Screw presses for various seeds including dry larvae

- $1000.00 /set

- 1 set

- Henan Eternalwin Machinery Equipment Co., Ltd.

- Henan, China

- Mr Steven Li

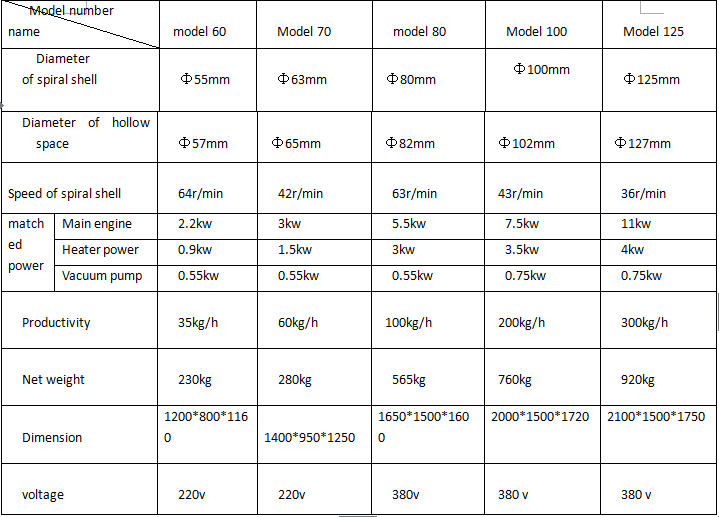

| Delivery Details: | 10-15 working days after receiving your payment | place of origin; place of origin: | Henan, China |

| type: | Hot and cold press | Material: | Carbon Steel and 304 Stainless Steel |

| weight: | Net weight 920kg | Auto grade: | automatic |

| port: | Shanghai Qingdao Ningbo Shenzhen Hangzhou any port as your request | usage: | sesame oil |

| brand: | Yongsheng | product name: | Making a variety of seed dried larvae oils |

| application: | larvae that press various seeds to dry | Function: | Dry larvae for pressing various seeds |

| model: | 6YL-125 | capacity: | 7.2 tons/day |

| Name: | Screw press for various seeds including dried larvae | color: | as customer's request |

| Supply capacity: | 1000 sets per month | Health status: | new |

| Dimensions (L*W*H): | 2100*1500*1750 | Advantage: | Efficient and fully automatic |

| strength: | 11kW | Packaging Details: | Packaging Details: Wooden case packing, plastic warp. Standard export packaging |

| payment terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram,L/C,D/P,T/T,Western Union,MoneyGram,cash | Voltage: | 380V/50HZ |

| After-sales service provided: | Engineers can repair machinery overseas | Certification: | ISO CE SGS |

| Production capacity: | 100% | Raw materials: | Various seed drying larvae |

| Warranty: | 12 months |

Applications

1. High oil yield: Directional pressurization, multi-stage propulsion, one pressing is completed.

2. High output:Strengthen the feeding system, the process is fast and the efficiency is high.

3. Automatic temperature control:Electrical program control, scientific heating, automatic temperature control.

5. Safe and convenient:The structure is compact and the floor space is small; the transmission system adopts closed protection.

6. Beautiful:This machine adopts the latest electrostatic coating material, which has strong adhesion, grease resistance and high temperature resistance. It's beautiful and easy to clean.

7. Durable:High-quality wear-resistant steel and anti-fatigue castings ensure stable performance and long-term continuous work.

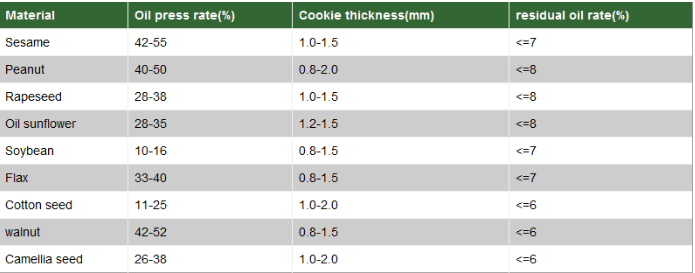

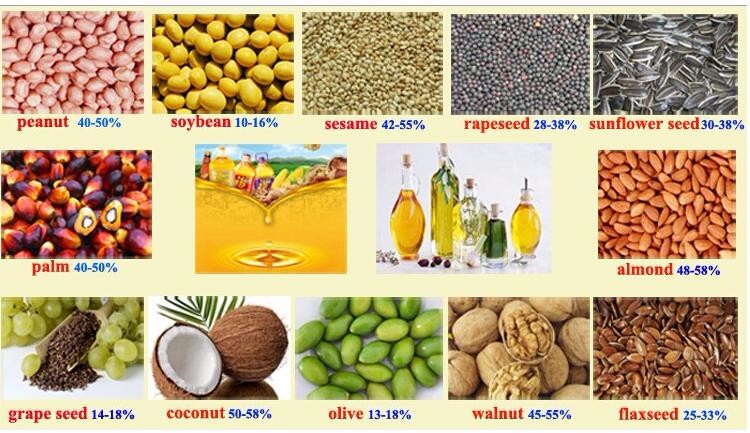

Suitable seed types:

Our screw press can improve oil yield. Below is the oil yield from the seeds.

Below are spare parts.

The machine consists of a feeder, a gear box, a pressing cage, a screw shaft and a machine base.

(1) There are grooves on both sides of each row of screws to ensure that the material rotates in the press cage and the material is fully compressed.

The screw row is slotted, which can increase the oil yield by 5%.

(2) The screw row spacing is very small, which ensures that the material is fully pressurized and improves the oil yield.

The screw oil press directly affects the residual oil rate of the screw oil press and the oil cake. The automatic screw oil press rotates in the press ring through the oil press, forming a certain thrust on the material, and gradually forming the oil press and the oil press ring. The oil narrowed to the volume of the material is squeezed out from a crack in the cage bar. There are multiple presses on the central axis of the cage, and the adjacent presses are connected by a lining. After the material is crushed, the dry residue Discharge through the discharge port.

All models of oil presses are equipped with two vacuum oil filters, as shown in the picture below, after the oil is pressed, the oil will be filtered by the vacuum oil filters, which removes impurities and makes the oil cleaner and healed

The circuit control part is composed of air switch, AC contactor, automatic protection device of temperature control instrument, etc.

1 shipment: We will be responsible for shipping details and arrange related matters according to customer requirements.

2 production: We arrange production after receiving the deposit from the customer. We can ship within 10 days after receiving the deposit.

3 Installation. We will install before shipping. That is to say, after customers get our machines, they can be directly used for oil extraction.

4 supporting equipment. For some special raw materials, such as copra, we also provide copra crusher and roaster.

5: Export experience.We have been in this field for many years. We can help customers with all related questions about export procedures.

6 Operating Instructions. When our customers get our machines, we can also teach the operating procedures to the customers via the Internet. We will make customers understand the mechanical operation in a short time.

Q1: How is the quality of your oil processing plant?

A1: Our products are manufactured strictly according to national and international standards, and we test each oil press before leaving the factory. We have CE certification and various test reports; please ask us for it if you wish.

Q2: What is waOil Processing Plant Warranty?

A2: Our products are of high quality and we can provide a 12-month warranty. Warranty is much longer than any other similar product.

Q3: Can special products be produced according to customer requirements?

A3: Of course the answer is yes. you canContact us directly.

Q4: How can customers ensure that they can get the product on time?

A4: If we can't deliver the product within the time ordered, we can refund 100% of your money. The third part, SGS can also help you to check the machine before shipment.

Please confirm the following details before purchasing our products, your detailed inquiry will help us to provide you with suitable machines and more favorable prices.

Q5. Can I use my own raw materials for extraction test?

Yes of course. We can perform extraction tests and send you videos and test reports for your reference.

Q6. What material is your machine made of?

Carbon steel or stainless steel (standard model is SUS304, can be customized according to your requirements)

Q7. What is the minimum quantity I have to order?

Minimum order one set, if you order more than 3 sets at a time, we can give you

bigger discount.

Q8. How will my order be packed, can you provide installation service?

Packed in a plywood box.

We will send English manuals. If the customer needs, we will send an engineer to assemble and train the workers. 80 US dollars per person per day, food, accommodation and air tickets are borne by the customer.

Question 9. How does the machine adapt to our voltage?

Before shipping the machine, our sales staff will confirm the voltage with the customer.

Contact me:

If you want to know more questions or have any questions, please feel free to let me know.