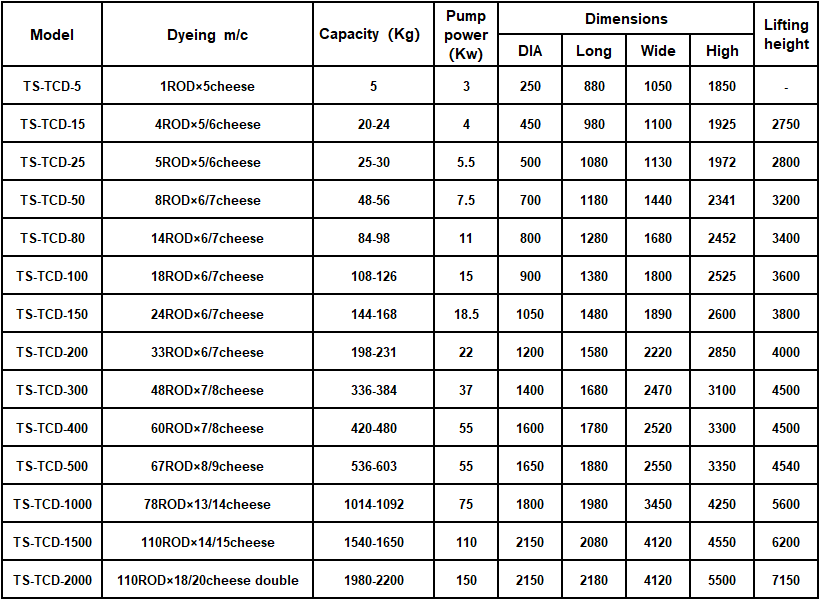

Small yarn dyeing machine

- $2420.00 /unit

- 1 unit

- Guangzhou Zhenyu Zipper Machines Co., Ltd.

- Guangdong, China

- Ms ZY ZM

| place of origin; place of origin: | Guangdong, China | Core components: | PLC, motor, pump |

| Showroom location: | not any | Marketing Type: | normal product |

| Voltage: | 380V | Applicable industries: | fabric dyeing, textile dyeing, yarn dyeing |

| Packaging Preview: | Health status: | new | |

| Warranty: | 1 year | Supply capacity: | 100 units per month |

| brand: | Dyeing technology | weight: | 50kg |

| payment terms: | letter of credit, wire transfer | Packaging Details: | wooden box |

| Auto grade: | semi-automatic | After Warranty Service: | Online support |

| port: | Guangzhou, Shenzhen, Shanghai | Mechanical test report: | if |

| Core Components Warranty: | 1 year | After-sales service provided: | Video technical support |

| Video external inspection: | if |

application:

Hthp dyeing machine, Hthp yarn dyeing machine, tube yarn dyeing machine, Hthp vertical dyeing machine, tube yarn dyeing machine, cheese yarn dyeing machine, yarn dyeing machine manufacturer, Surat yarn dyeing machine manufacturer mainly applies to Processing cotton, wool, linen, polyester-cotton, polyester, etc. ... The twisted yarn of natural fibers and their blended fabrics is below 140 °C (such as dyeing, boiling, blanching, cleaning, etc.).

feature:

1. Circulating dye flow control According to different yarn and dyeing process requirements, the main pump frequency conversion control system can save energy and give a reasonable flow to realize the optimization of synchronous dyeing control.

2. The compact flow commutator eliminates the commutation pause, increases the number of cycles, and makes the dyeing more uniform.

3. High-efficiency heat exchanger is adopted, and the heat transfer effect is good.

4. The design of low liquor ratio (1:3~1:8) saves dyes, auxiliaries and energy, reduces emissions and improves economic benefits.

5. The variable load spindle enables the yarn amount to be changed horizontally to achieve a fixed bath ratio and enhance the processing flexibility.

6. Quick cleaning system, effectively saving cleaning time and water consumption.

7. The overflow feeding system can dynamically control materials, effectively control the feeding speed and feeding amount, and ensure uniform dyeing speed.

8. The new centrifugal circulating pump is adopted, with high performance and high efficiency, saving water replenishment and drainage time.

Other Products

-

High temperature and high pressure package yarn dyeing machine$2700.00 / set

High temperature and high pressure package yarn dyeing machine$2700.00 / set -

Medical gauze or absorbent cotton production line$22000.00 / set

Medical gauze or absorbent cotton production line$22000.00 / set