SunGlory kitchen utensils making machine milk hot tea water electric temperature control kettle kettle spare parts heating tube

- $0.26 / >=5000 sets

- 5000 sets

- Guangzhou Shangguan Machinery Co., Ltd.

- Guangdong, China

- Ms Crystal Huang

PRODUCT DETAIL

| brand: | sun glory | usage: | electric kettle thermostat |

| Warranty: | 1 year | Packaging Details: | Metal frame and film wrap |

| type: | electric kettle parts | port: | Shenzhen |

| payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram | After-sales service provided: | Free spare parts, on-site installation, on-site maintenance and repair service, overseas call center |

| Origin: | Guangdong, China | Energy source: | electrical |

| Supply capacity: | 10 sets per month | application: | hotel, garage, commercial, home |

| model: | JH21-25 | product name: | electric kettle thermostat |

Product Description

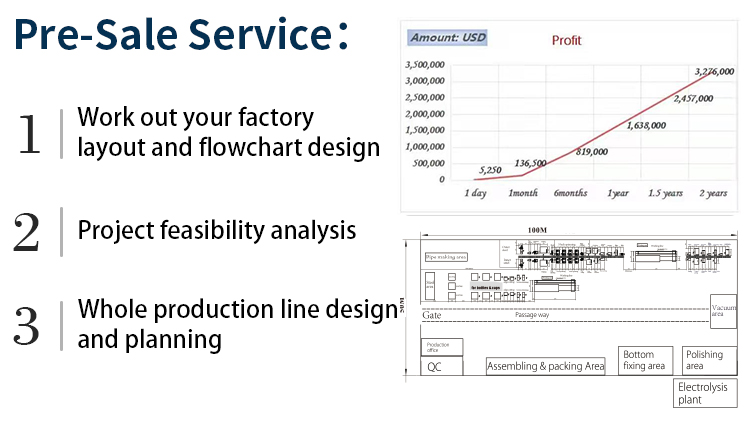

engineering service

Partner with us and you can have a full line of stainless steel pots, pans, pressure cookers, kettles and more.

With 20-50 years of experience in production technology and machinery, dedicated to the establishment of AZ turnkey projects (semi-automatic 2.0 and fully automatic 3.0) and part of the production line to improve automation, efficiency and quality of the new factory manufacturing metal forming, edge cutting beading, cleaning lines , brazing and impact bonding, polishing and grinding, non-stick paint and powder coating, and other metalworking.

Our services and technologies are as follows: 1. Project investment feasibility analysis report;

2. The layout planning and design of the whole factory building, including the production process flow chart, water, electricity and compressed air circuit diagram.

3. Guidelines for vacuuming systems in polishing workshops.

4. Customized production line, including machines, molds (stainless steel/aluminum discs provided by customers) and tools, accessories,

Consumables and supporting equipment.

5. Trial production to meet the requirements of the final product samples before shipment (customer to provide stainless steel / aluminum plate).

6. First training and evaluation of machine operation and maintenance for production managers, supervisors and engineers (optional: fee to be paid by buyer).

7. The buyer's factory installation, commissioning and training (the responsible sales engineer is on-site).

8. Industry-leading machine manufacturing capabilities and product processing technology research and development, with independent property rights, total

There are more than 600 employees and more than 120 technicians in our factory.

9. Service 15 sales engineers 7 * 24 hours online 50 after-sales engineers on-site support 2 service centers in India.

10. In-kind support for production technology and management in the buyer's factory by production experts for 11 months (the buyer bears the cost and wages).

11. New product development and manufacturing process optimization. Since 1988, we've refined the techniques used to manufacture the world's stainless steel and aluminum cookware, hospitality supplies, tableware, and water bottles and thermoses. We got it? Patents and our technology and workmanship are always in the leading position in the industry.

80% of customers can recover all equipment investment within 5-18 months through reasonable analysis and planning, high-quality service and timely technical support under the condition of good orders. So our cross-industry customers can quickly occupy the leading position in the industry within 3-5 years, and even grow into the industry Top 1, and those factories that have been engaged in manufacturing for many years can consolidate their industry leadership to fight in the fierce competition. Quality Control and Certificate: SGS Audit Certificate,

CE, ISO, TUV. We attach great importance to the research and development of product manufacturing technology and new design, cultivate the moral quality of employees, and improve the technical level of employees.

2. The layout planning and design of the whole factory building, including the production process flow chart, water, electricity and compressed air circuit diagram.

3. Guidelines for vacuuming systems in polishing workshops.

4. Customized production line, including machines, molds (stainless steel/aluminum discs provided by customers) and tools, accessories,

Consumables and supporting equipment.

5. Trial production to meet the requirements of the final product samples before shipment (customer to provide stainless steel / aluminum plate).

6. First training and evaluation of machine operation and maintenance for production managers, supervisors and engineers (optional: fee to be paid by buyer).

7. The buyer's factory installation, commissioning and training (the responsible sales engineer is on-site).

8. Industry-leading machine manufacturing capabilities and product processing technology research and development, with independent property rights, total

There are more than 600 employees and more than 120 technicians in our factory.

9. Service 15 sales engineers 7 * 24 hours online 50 after-sales engineers on-site support 2 service centers in India.

10. In-kind support for production technology and management in the buyer's factory by production experts for 11 months (the buyer bears the cost and wages).

11. New product development and manufacturing process optimization. Since 1988, we've refined the techniques used to manufacture the world's stainless steel and aluminum cookware, hospitality supplies, tableware, and water bottles and thermoses. We got it? Patents and our technology and workmanship are always in the leading position in the industry.

80% of customers can recover all equipment investment within 5-18 months through reasonable analysis and planning, high-quality service and timely technical support under the condition of good orders. So our cross-industry customers can quickly occupy the leading position in the industry within 3-5 years, and even grow into the industry Top 1, and those factories that have been engaged in manufacturing for many years can consolidate their industry leadership to fight in the fierce competition. Quality Control and Certificate: SGS Audit Certificate,

CE, ISO, TUV. We attach great importance to the research and development of product manufacturing technology and new design, cultivate the moral quality of employees, and improve the technical level of employees.

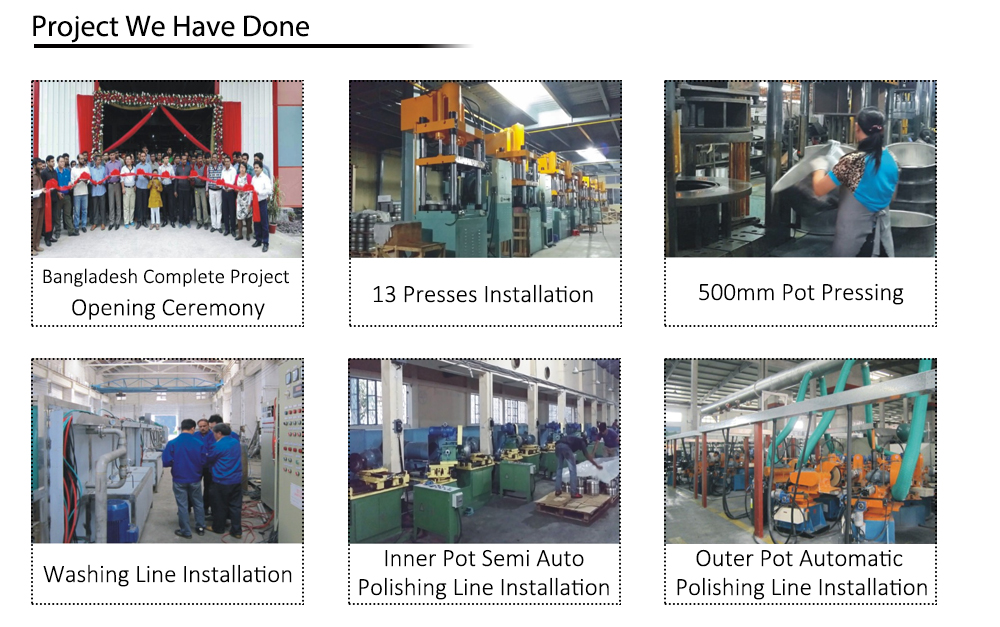

In the past 6 years, we have accumulated an export volume of nearly 17 million US dollars and successfully completed 55 projects, such as: 1. India:

20A-Z production line and automatic polishing line; 2. Thailand: 5 AZ production lines; 2. Egypt and Vietnam: 4 AZ production lines

lines and polished lines;

3. Bangladesh: 3 AZ production lines and polishing lines;

4. Indonesia: 3 AZ production lines;

5. Pakistan: 2 AZ production lines;

6. One AZ production line in Russia, Mexico, Peru, Algeria, Ethiopia, Kenya, Uzbekistan, Nepal and Dubai, United Arab Emirates;

7. Spinning production line: Thailand, Indonesia, Mexico;

8. Argentina: 1 polishing line.

9. Sri Lanka: 1 cleaning line.

20A-Z production line and automatic polishing line; 2. Thailand: 5 AZ production lines; 2. Egypt and Vietnam: 4 AZ production lines

lines and polished lines;

3. Bangladesh: 3 AZ production lines and polishing lines;

4. Indonesia: 3 AZ production lines;

5. Pakistan: 2 AZ production lines;

6. One AZ production line in Russia, Mexico, Peru, Algeria, Ethiopia, Kenya, Uzbekistan, Nepal and Dubai, United Arab Emirates;

7. Spinning production line: Thailand, Indonesia, Mexico;

8. Argentina: 1 polishing line.

9. Sri Lanka: 1 cleaning line.

customer photo

VIEW MORE