Wood pellet machine German market biomass waste wood pellet machine wood pellet machine

- $1099.00 / 1 - 4 pieces

$799.00 / 5 - 9 pieces

$599.00 / >=10 pieces - 1 piece

- Zhengzhou Songbai Machinery Equipment Co., Ltd.

- Henan, China

- Ms Grace Qin

PRODUCT DETAIL

| Output (kg/hour): | 100 - 4000 kg/h | Dimensions (length*width*height): | 100X45X85CM |

| Ideal humidity: | Biomass pellets 10-15% | Power (kW): | 7.5kW-200kW |

| Applicable industries: | Hotels, clothing stores, building materials stores, manufacturing plants, food and beverage plants, farms, household, retail, energy and mining, food and beverage stores | Supply capacity: | 100 pieces per month |

| Voltage: | 380V/220V | Main selling points: | long lasting |

| Health status: | new, new | Key words: | wood branch sawdust wood pellet machine manufacturer wood pellet machine |

| Particle size: | 6/8/10/12mm customized | Place of origin: | Henan, China |

| warranty period: | one year | Warranty: | 1 year |

| Package preview: | Core components: | Bearings, motors, gears | |

| Packaging details: | wooden box | Mechanical test report: | if |

| Motor power (kW): | 7.5kW-200kW | payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram, Trade Insurance |

| raw material: | Alfalfa\Woodchips\Straw\Rice Husk\Wood Waste | Weight (kg): | 437kg |

| Core component warranty: | 1 year | product name: | Biomass waste wood pellet machine wood pellet machine |

| port: | Qingdao\Shanghai\Tianjin | Particle diameter (mm): | 4-12 |

| Machine name: | Wood pellet machine biomass wood pellets | Processing raw materials: | Grass, rice husk, sawdust, biomass, straw, cotton stalk |

| application: | Farm, home use, fuel plants, energy and mining, manufacturing wood pellets | Type of machine: | Biomass fuel wood pellet machine |

| Video outbound inspection: | if | Marketing type: | normal product |

Product Description

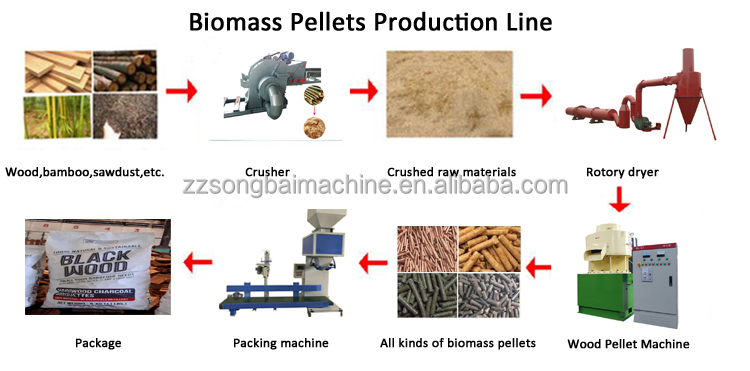

Introduction to biomass wood pellet machine

Our wood pellet machine is a mature energy-saving equipment. This kind of wood pellet machine is easy to operate and maintain and has a low price. The finished pellets are biofuels of biomass energy, which can replace coal, oil, natural gas, etc., and are widely used in power plants, boilers, and heating systems. Its hardness is close to European standards. Pellet fuel is a clean, renewable energy source that is easy to manufacture, package, store and transport.

This machine makes full use of wood, sawdust, wood chips, straw, rice husks, peanut shells and other waste materials to help you save money, make money and protect the environment.

Our wood pellet machine is a mature energy-saving equipment. This kind of wood pellet machine is easy to operate and maintain and has a low price. The finished pellets are biofuels of biomass energy, which can replace coal, oil, natural gas, etc., and are widely used in power plants, boilers, and heating systems. Its hardness is close to European standards. Pellet fuel is a clean, renewable energy source that is easy to manufacture, package, store and transport.

This machine makes full use of wood, sawdust, wood chips, straw, rice husks, peanut shells and other waste materials to help you save money, make money and protect the environment.

Specification

We have multiple models of wood pellet machines according to different pellet production, you can check the specifications below to choose your favorite model, if you have any interest, you can contact us at any time, we will be happy to provide you with more professional recommend you.

Uses of wood pellet machine

Mainly used in households and small processing plants, mainly used for wood, straw, cotton stalks, rice husks, peanut shells, bamboo, empty fruit branches, coal powder, waste paper, etc. Product advantages are high density, high fuel value, low moisture and low ash content, and the machine operates through reduction gears. Details are as follows:

Mainly used in households and small processing plants, mainly used for wood, straw, cotton stalks, rice husks, peanut shells, bamboo, empty fruit branches, coal powder, waste paper, etc. Product advantages are high density, high fuel value, low moisture and low ash content, and the machine operates through reduction gears. Details are as follows:

Model | Rated power-KW | Capacity-KG/H | Product size-CM | Weight-KG |

SKJ200 | 7.5 | 100-150 | 100X45X85 | 260 |

SKJ250 | 15 | 200-250 | 120X55X105 | 550 |

SKJ300 | twenty two | 250-300 | 125X60X110 | 590 |

Industrial (commercial) uses of wood pellet machines

Suitable for small pellet production lines or industrial pellet plants.

We also have large capacity wood pellet machines from 55KW to 200KW for wood pellet production for industrial (commercial) applications.

If you want a production capacity greater than 800kg/h, we recommend a vertical ring-die granulator. Details are as follows:

Suitable for small pellet production lines or industrial pellet plants.

We also have large capacity wood pellet machines from 55KW to 200KW for wood pellet production for industrial (commercial) applications.

If you want a production capacity greater than 800kg/h, we recommend a vertical ring-die granulator. Details are as follows:

Model | Rated power-KW | Capacity-KG/H | Product size-CM | Weight-KG |

SKJ350 | 30 | 400-500 | 135X80X130 | 1000 |

SKJ450 | 37 | 600-700 | 130X70X150 | 1450 |

SKJ500 | 55 | 800-1200 | 140X75X155 | 2200 |

SKJ550 | 90 | 1500-2000 | 190X95X180 | 4000 |

SKJ800 | 160 | 2000-3000 | 250X135X210 | 6500 |

SKJ1000 | 200 | 3000-4000 | 265X145X210 | 8000 |

Our wood pellet machine is equipped with automatic lubrication system and cooling dust removal system

1. Adopt automatic lubrication system to ensure 24-hour continuous operation.

--Automatic lubrication system for gearbox

--Automatic roller lubrication system

2. Cooling and dust removal system:

--Reduce the temperature of the working space of the wood pellet machine, and the wood pellet machine will work more stably.

--Removes dust and water vapor to ensure low moisture quality of the final pellets.

——Greatly improve the working environment of workers.

1. Adopt automatic lubrication system to ensure 24-hour continuous operation.

--Automatic lubrication system for gearbox

--Automatic roller lubrication system

2. Cooling and dust removal system:

--Reduce the temperature of the working space of the wood pellet machine, and the wood pellet machine will work more stably.

--Removes dust and water vapor to ensure low moisture quality of the final pellets.

——Greatly improve the working environment of workers.

Applications

Development prospects of biofuel pellet production

Wood pellets have many economic and ecological advantages as a fuel compared to coal, natural gas and fuel oil. Pellets prices develop largely independently of gas and oil prices, which will continue to rise as resources become scarce and ecological taxes increase.

In terms of fuel prices, pellets are already a cost-effective alternative to fossil fuels. In addition, job opportunities are being created

In areas with extensive timber and forestry.

Environmental pollution caused by tanker accidents and natural gas pipeline leaks will not occur when using pellet fuel. The risk of explosions, fires and groundwater contamination when storing fuels is also significantly reduced compared to fossil fuels.

Wood pellets are standardized cylindrical briquettes made from dried natural leftover wood, approximately 100 mm in diameter. 4 - 10 mm, length 20 - 45 mm. So-called sawmill by-products such as sawdust or shavings are used in production. They are manufactured under high pressure, without the addition of chemical binders, and have a calorific value of approximately 5 kWh/kg. This means that one kilogram of pellets has an energy content roughly equivalent to that of half a liter of heating oil.

Wood pellets have many economic and ecological advantages as a fuel compared to coal, natural gas and fuel oil. Pellets prices develop largely independently of gas and oil prices, which will continue to rise as resources become scarce and ecological taxes increase.

In terms of fuel prices, pellets are already a cost-effective alternative to fossil fuels. In addition, job opportunities are being created

In areas with extensive timber and forestry.

Environmental pollution caused by tanker accidents and natural gas pipeline leaks will not occur when using pellet fuel. The risk of explosions, fires and groundwater contamination when storing fuels is also significantly reduced compared to fossil fuels.

Wood pellets are standardized cylindrical briquettes made from dried natural leftover wood, approximately 100 mm in diameter. 4 - 10 mm, length 20 - 45 mm. So-called sawmill by-products such as sawdust or shavings are used in production. They are manufactured under high pressure, without the addition of chemical binders, and have a calorific value of approximately 5 kWh/kg. This means that one kilogram of pellets has an energy content roughly equivalent to that of half a liter of heating oil.

VIEW MORE

Other Products

-

Energy-saving charcoal carbon stove smokeless coconut shell bamboo bio charcoal grill machine$750.00 - $1350.00 / piece

Energy-saving charcoal carbon stove smokeless coconut shell bamboo bio charcoal grill machine$750.00 - $1350.00 / piece -

Hot sale 600kg/h wood sawdust dryer small piece rice husk biomass powder tube airflow dryer with CE for sale$3200.00 - $4150.00 / piece

Hot sale 600kg/h wood sawdust dryer small piece rice husk biomass powder tube airflow dryer with CE for sale$3200.00 - $4150.00 / piece