stainless steel axial fan with aluminum alloy blades

- $30.00 / 1 - 19 pieces

$28.00 / >=20 pieces - 1 piece

- Qingdao Pengsheng Electric Appliance Co., Ltd.

- Shandong, China

- Ms feng huang

| Fan material: | Stainless steel | Supply capacity: | 1000 pieces per week stainless steel axial fans with aluminum alloy blades |

| port: | Qingdao | frame: | steel frame |

| payment terms: | letter of credit, wire transfer | Blade material: | Stainless steel |

| place of origin; place of origin: | Shandong China | Install: | Detached |

| Voltage: | 220V/380V/440V, 220V/380V/440V | Certification: | ISO9001 |

| brand: | Pengsheng | weight: | custom made |

| noise: | low | Warranty: | 1 year |

| After-sales service provided: | Free spare parts, provide overseas service center | current: | alternating current |

| type: | Detached | type: | Axial Fan |

| Packaging Details: | Stainless steel axial fan with aluminum alloy blades plywood or as your request | thing: | Stainless Steel Axial Fan with Aluminium Alloy Blades |

| strength: | 3KW |

Stainless Steel Axial Fan with Aluminium Alloy Blades

High temperature resistant axial flow fanSpecifically designed for tobacco drying, wood drying and more. The fan motor adopts F-class and H-class insulation.

1. Features: high temperature resistance, high humidity resistance, high efficiency and large air volume. Low noise, energy saving, etc.

2. Blades: The fan adopts four arc-shaped aluminum blades, and the angle of the blades can be adjusted according to the user's needs.

3. Uses: high temperature and high humidity places such as tobacco drying, wood drying kiln, etc.

| Model | spinning speed | air flow | total pressure | motor | |

| Do not. | number of revolutions | m3/hour | Pa | motor model | Power (kW) |

| 2.5 | 2900 | 2200-1400 | 120-160 | 631-2 | 0.18 |

| 2500-1500 | 130-170 | 632-2 | 0.25 | ||

| 1450 | 1600-1000 | 55-60 | 631-4 | 0.12 | |

| 3 | 2900 | 3200-1800 | 120-180 | 632-2 | 0.25 |

| 3500-2000 | 140-200 | 633-2 | 0.37 | ||

| 1450 | 2200-1200 | 60-80 | 631-4 | 0.12 | |

| 3.5 | 2900 | 4500-1200 | 200-250 | 711-4 | 0.37 |

| 5200-3000 | 250-280 | 712-2 | 0.55 | ||

| 1450 | 3500-4000 | 80-100 | 711-4 | 0.25 | |

| 4 | 2800 | 5500-3000 | 230-300 | 712-2 | 0.55 |

| 6500-4000 | 250-330 | 801-2 | 0.75 | ||

| 7500-5000 | 270-380 | 802-2 | 1.1 | ||

| 1450 | 4300-2500 | 40-80 | 711-4 | 0.25 | |

| 5000-2800 | 100-120 | 712-4 | 0.37 | ||

| 5200-3200 | 70-90 | 713-4 | 0.55 | ||

| 5 | 2400 | 12000-7000 | 360-480 | 100L-2 | 3 |

| 2900 | 10000-5000 | 250-600 | 90L-2 | 2.2 | |

| 12000-7000 | 400-620 | 100L-2 | 3 | ||

| 1450 | 7000-4500 | 110-140 | 712-4 | 0.37 | |

| 7500-5000 | 115-150 | 801-4 | 0.55 | ||

| 8700-5400 | 140-170 | 802-4 | 0.75 | ||

| 9000-6000 | 190-210 | 802-4 | 0.75 | ||

| 9500-6500 | 200-220 | 90S-4 | 3 | ||

| 960 | 6300-4300 | 84-92 | 801-6 | 2.2 | |

| 5.5 | 1450 | 10000-6500 | 180-210 | 802-4 | 3 |

| 11000-7500 | 190-210 | 60S-4 | 0.37 | ||

| 960 | 7300-5000 | 80-88 | 801-6 | 0.55 | |

| Model | spinning speed | air flow | total pressure | motor | |

| Do not. | number of revolutions | m3/hour | Pa | motor model | Power (kW) |

| 6 | 2400 | 15000-8000 | 250-460 | 112M-2 | 4 |

| 3900 | 15000-8000 | 250- 650 | 100L-2 | 3 | |

| 1450 | 15000-8000 | 195-220 | 90S-4 | 1.1 | |

| 14500-9000 | 250-280 | 90L-4 | 1.5 | ||

| 16000-10000 | 270-310 | 100L1-4 | 2.2 | ||

| 960 | 8500-5000 | 90-100 | 801-6 | 0.37 | |

| 9600-6000 | 105-144 | 802-6 | 0.55 | ||

| 7 | 1450 | 18000-11000 | 170-250 | 90L-4 | 1.5 |

| 20500-13000 | 200-275 | 100L1-4 | 2.2 | ||

| 21500-13500 | 265-370 | 100L2-4 | 3 | ||

| 960 | 14000-9000 | 90-120 | 90S-6 | 0.75 | |

| 15000-10000 | 100-130 | 90L-6 | 1.1 | ||

| 8 | 1450 | 25000-16000 | 200-320 | 100L1-4 | 2.2 |

| 29000-20000 | 220-340 | 100L2-4 | 3 | ||

| 32000-22000 | 300-400 | 112M-2 | 4 | ||

| 35000-25000 | 320-420 | 132S-4 | 5.5 | ||

| 960 | 21000-14500 | 130-175 | 100L-6 | 1.5 | |

| 24000-16500 | 140-190 | 112M-6 | 2.2 | ||

| 9 | 1450 | 37000-24000 | 300-450 | 132S-4 | 5.5 |

| 40000-27000 | 320-470 | 132M-4 | 7.5 | ||

| 42000-30000 | 330-480 | 160M-4 | 11 | ||

| 960 | 26500-15000 | 170-205 | 112M-6 | 2.2 | |

| 29000-18000 | 180-230 | 132S-6 | 3 | ||

| 32000-21000 | 210-250 | 132M1-6 | 4 | ||

| 36000-23000 | 250-320 | 132M2-6 | 5.5 | ||

| 10 | 1450 | 42000-34000 | 330-470 | 132S-4 | 5.5 |

| 46000-38000 | 350-480 | 132M-4 | 7.5 | ||

| 52000-43000 | 400-500 | 160M-4 | 11 | ||

| 56000-46000 | 490-610 | 160L-4 | 15 | ||

| 60000-480000 | 500-640 | 180M-4 | 18.5 | ||

| 960 | 33000-21000 | 200-230 | 132M1-6 | 4 | |

| 40000-27000 | 260-290 | 132M2-6 | 5.5 | ||

| 730 | 32000-20000 | 160-180 | 132S-8 | 3 | |

| 38000-26000 | 170-200 | 160M1-8 | 4 | ||

1. Heat and moisture proof, durable

The cage is made of galvanized steel sheet, with no welds as a whole, and the surface is sprayed with plastic, which is heat-resistant, moisture-proof and has a long service life.

2. Low noise and stable operation

The impeller is composed of forward multi-blade arc blades, front plate and middle plate. The material is made of galvanized sheet. In order to ensure the accuracy of the impeller, all parts of the impeller are formed by die stamping. The impeller has been corrected by static and dynamic balance, with small vibration, low noise and stable operation during operation.

3. Motor

The fan adopts an external rotation low-noise three-phase asynchronous motor, and the impeller and the motor are connected by bolts, which reduces the transmission loss and improves the overall efficiency of the fan.

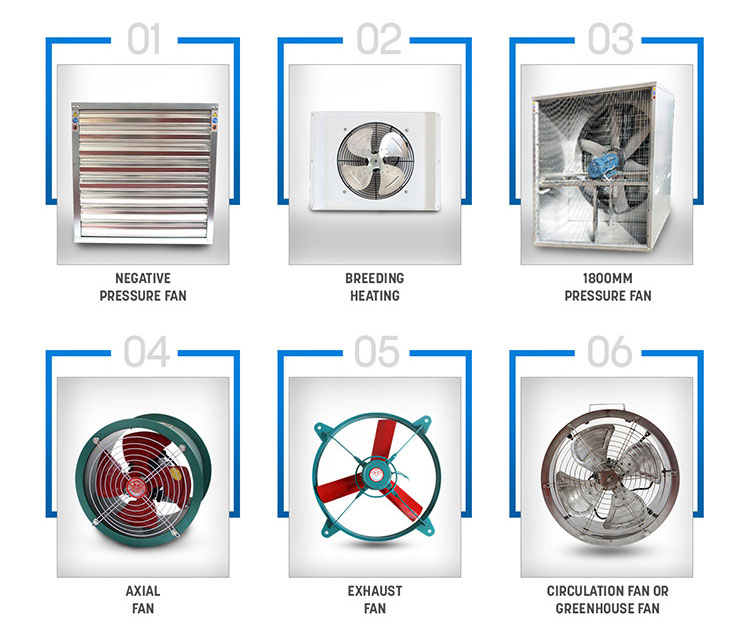

↑Each picture has a link, you can choose the one you are interested in and click it ↑