3d house printer concrete construction mold house machine

- $46000.00 /set

- 1 set

- Hubei Tengcang Building Materials Technology Co., Ltd.

- Hubei, China

- Mr Sam Xiao

PRODUCT DETAIL

| Payment Terms: | L/C,T/T,Western Union,MoneyGram; | Weight: | 17000-23000KG; |

| Automation: | Semiautomatic; | Showroom Location: | None; |

| Core Components: | PLC,Engine,Bearing,Gearbox,Motor,Pressure vessel,Gear,Pump; | Place of Origin: | China; |

| Video outgoing-inspection: | Provided; | Machine Material: | Full Steel; |

| Marketing Type: | Hot Product 2019; | Application: | civil houses and public buildings; |

| Condition: | New; | Production Method: | RC Filling; |

| Warranty of core components: | 1 Year; | Machinery Test Report: | Provided; |

| Applicable Industries: | Hotels,Garment Shops,Building Material Shops,Machinery Repair Shops,Manufacturing Plant,Food & Beverage Factory,Farms,Restaurant,Home Use,Retail,Food Shop,Printing Shops,Construction works ,Energy & Mining,Food & Beverage Shops,Advertising Company; | Local Service Location: | None; |

| UNIQUE SELLING POINT: | Fully hydraulic system; | After-sales Service Provided: | Video technical support,Field installation, commissioning and training,Field maintenance and repair service,Free spare parts,Online support; |

| Dimension(L*W*H): | 3*6m, 3.3*6.6m, 3.6*7.2m; | Warranty: | 1 Year; |

| Size: | 3*6m, 3.3*6.6m, 3.6*7.2m; | Production Capacity: | 2-3 Hours; |

| Brand Name: | TC; | Principle: | Principle; |

| Packaging Detail: | packed in wooden box.; | Port: | wuhan,shanghai,ningbo,any port in china; |

| After Warranty Service: | Video technical support,Online support,Spare parts,Field maintenance and repair service; | Inner Box: | Shrinkable; |

| Full Steel: | Slidable; | Supply Ability: | 100 Sets per Month; |

| Forming Time: | 2-3Hours; | If Can Be Customized: | Yes; |

Product Description

Concrete modular house is also called precast concrete house,belonging to concrete assembly building.It is a new type of construction method with good energy saving and low construction cost. It adopts reinforced concrete structure, which is prefabricated into unit modules in the factory through special equipment, and then directly transported to the site for assembly.

The level of prefabrication is high, the size is accurate, the construction speed is very fast, and 500 square meters can be built in one day, which greatly increases the construction speed. It realized the industrial production of concrete houses

The level of prefabrication is high, the size is accurate, the construction speed is very fast, and 500 square meters can be built in one day, which greatly increases the construction speed. It realized the industrial production of concrete houses

Machine details

We need six machines to finished the production

House Forming Machine (Type:TC8010) | ||

Principle | Hydraulic | |

Automation | Semiautomatic | |

Production Method | RC Filling | |

Forming Time | 2-3Hours | |

Machine Material | Full Steel | |

Side Sheet | Slidable | |

Inner Box | Shrinkable | |

Weight | 17000-23000KG | |

Size | 3*6m, 3.3*6.6m, 3.6*7.2m | |

If Can Be Customized | Yes | |

House Quick-solidifying Machine A (Type:TC8021) | ||

Efficiency | 500kg/h Evaporation | |

Preset Pressure | 0.7Mpa | |

Temperature | 170celsius | |

Voltage | 380V | |

Power | 1.4kw | |

Weight | 2500kg | |

Size | Diameter 1m, Height 2.6m | |

CNC Rebar Processing Machine (Type:TC8030) | ||

Processing Speed | 20-40m/min | |

Processing Diameter | 4-14mm Rebar | |

Rebar Type | Round Rebar, Deformed Rebar | |

Principle | Hydraulic | |

Control System | CNC | |

Voltage | 380V | |

Power | 9kw | |

Machine Size | 200*75*110cm | |

Weight | 900kg | |

Concrete Mixing Plant

Concrete Mixer A(Type:TC8041) | ||

Feed Volume | 800L | |

Discharge Volume | 500L | |

Efficiency | 25m³/h | |

Rotating Speed | 35r/min | |

Aggregate Size | Max 80mm | |

Blades | 14 PC | |

Voltage | 380V | |

Power | 18.5kw | |

Machine Size | 428*279*651mm | |

Weight | 3950kg | |

Batching Machine A(Type:TC8051) | ||

Weighing Volume | 800L | |

Storage Hopper | 5m³ | |

Efficiency | 48m³/h | |

Batching Error | ±1% | |

Max Weighing Value | 3000kg | |

Transfer Speed | 1m/s | |

Voltage | 380V | |

Power | 12kw | |

Machine Size | 560*183*270cm | |

Weight | 2450kg | |

Assembled Storage Tank A(Type:TC8061) | ||

Storage Weight | 80 ton | |

Tank Volume | 60m³ | |

Tank Diameter | 280cm | |

Straight Segment height | 900cm | |

Tank Total Height | 1105cm | |

Trestle Height | 300cm | |

Steel Thickness | 6mm | |

Weight | 3600kg | |

Accessories And Tools

Concrete Hopper 、Welder 、Wire Tope 、U-shaped Buckle 、Vibrating Rod、Cover Box .... And Others.

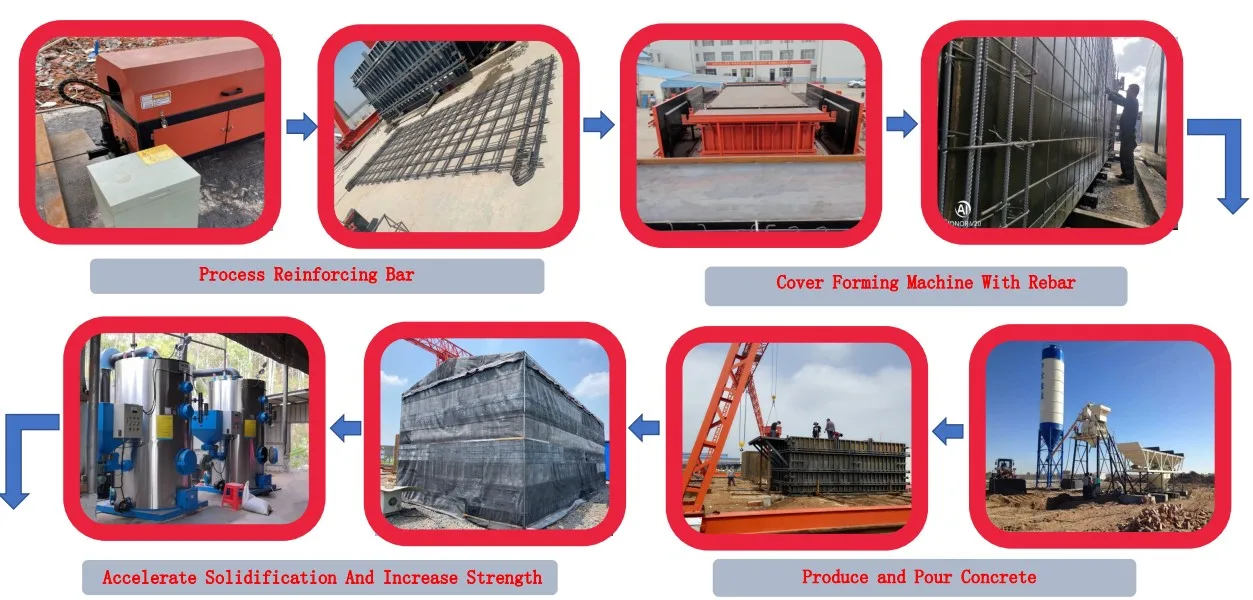

The production process of concrete modular house

1.Processing the rebar by CNC rebar Machine ,and weave the rebar (reinforcement)into grid and cover it on the inner chassis of forming machine.

2.Producing the concrete by the concrete machines.

3.Adjust the forming machine, and use the gantry crane and hopper to hoist the concrete and pour into the machine until it is full

4.Cover the forming machine with the cover of quick-solidifying machine,and then turn on quick-solidifying machine to make the concrete solidify quickly .

5.After 2-3 hours, a unit modular house is finished, pull open the side sheet of forming machine, adjust inner chassis shrink to detach the wall of house. Use the gantry crane hoist the house and store it.

2.Producing the concrete by the concrete machines.

3.Adjust the forming machine, and use the gantry crane and hopper to hoist the concrete and pour into the machine until it is full

4.Cover the forming machine with the cover of quick-solidifying machine,and then turn on quick-solidifying machine to make the concrete solidify quickly .

5.After 2-3 hours, a unit modular house is finished, pull open the side sheet of forming machine, adjust inner chassis shrink to detach the wall of house. Use the gantry crane hoist the house and store it.

Detailed Images

Concrete modular house features

The cost of building houses is low: the construction cost of this house is only half of traditional brick and concrete house.

Extreme speed of construction: high level of prefabrication, fast construction speed, 500 square meters per day, greatly improving construction speed

Earthquake resistance: It can withstand a magnitude 9 earthquake and will not collapse as a whole due to local damage during an earthquake.

Wind-resistant: It can withstand a hurricane of 200km/h. The weight of each unit module is 20 tons (the weight of 10 cars).

Long life: Lifetime of main structure with reinforced concrete can reach more than 100 years

Fire retardant: Reinforced concrete structure solid wall, fire resistance time is long.

Sound insulation: the amount of sound insulation of the wall can reach more than 65dB.

Insulation: Reinforced concrete structure solid wall, good thermal insulation

Energy-saving and environmental protection: new green buildings, doesn’t produce construction rubbish during construction, and can be removed again during demolition and reuse.

Flexible assembly: Can be assembled into all kinds of styles houses and buildings, each room can be assembled by one or more unit modules, up to five floors.

Extreme speed of construction: high level of prefabrication, fast construction speed, 500 square meters per day, greatly improving construction speed

Earthquake resistance: It can withstand a magnitude 9 earthquake and will not collapse as a whole due to local damage during an earthquake.

Wind-resistant: It can withstand a hurricane of 200km/h. The weight of each unit module is 20 tons (the weight of 10 cars).

Long life: Lifetime of main structure with reinforced concrete can reach more than 100 years

Fire retardant: Reinforced concrete structure solid wall, fire resistance time is long.

Sound insulation: the amount of sound insulation of the wall can reach more than 65dB.

Insulation: Reinforced concrete structure solid wall, good thermal insulation

Energy-saving and environmental protection: new green buildings, doesn’t produce construction rubbish during construction, and can be removed again during demolition and reuse.

Flexible assembly: Can be assembled into all kinds of styles houses and buildings, each room can be assembled by one or more unit modules, up to five floors.

Advantage

It is characterized by earthquake resistant and wind resistant, moisture proof and fireproof , sound insulation and heat insulation.

Compared with traditional brick and concrete houses, the main advantages of concrete modular houses are low construction cost, good earthquake resistance, long service life, fast construction speed, labor saving , long lifetime, no leaving construction rubbish, and can be removed when demolition. It is in line with the development direction of environmental protection construction advocated by the world.

Compared with traditional brick and concrete houses, the main advantages of concrete modular houses are low construction cost, good earthquake resistance, long service life, fast construction speed, labor saving , long lifetime, no leaving construction rubbish, and can be removed when demolition. It is in line with the development direction of environmental protection construction advocated by the world.

Show room

Packing&Shipping

Company Introduction

Hubei Tengcang building material technology company have built a new five-star Industrial Park, covering 23,000 square meters, located in the "Dongyong hometown"Wuhan city circle Hubei Xiaogan city National High-tech Development Zone, with research buildings, office buildings, standardized plant and automation equipment and other hardware facilities .we have more than 100 Scientific and technical staff, are specialized in producing the new decorative materials, construction materials, building materials ,building equipment and opto-electrical devices entity enterprise

FAQ

1.What are your terms of delivery?

We accept EXW, FOB, CFR, CIF, etc. You can choose the one which is the most convenient or cost effective for you.

2.Are you factory or trading company?

We are manufacturers

We are manufacturers

3. How big land I need to get for build a factory?

The land size should be 80m*40m at least.

The land size should be 80m*40m at least.

4. Does the concrete module can be customized to be any size?

Yes, it can be customized, the general sizes of one concrete module are:

Yes, it can be customized, the general sizes of one concrete module are:

Width*length: 3*6m, 3.3*6m, 3.3*6.3m, 3.3*6.6m, 3.5*7m, 3.6*6m, 3.6*6.6m, 3.6*7.2m.

Height: 2.8m,3m,3.2m,

Length of eaves: 0-1.5m.

Height: 2.8m,3m,3.2m,

Length of eaves: 0-1.5m.

Contact information

Cynthia Chen

Hubei Tengcang Building Materials Technology Co., Ltd.

Address: Xingbei Road, Sancha Town, Xiaonan District, Xiaogan, Hubei, China (Mainland)

Mobile/Wechat/WhatsApp:+86 13692109735

Cynthia Chen

Hubei Tengcang Building Materials Technology Co., Ltd.

Address: Xingbei Road, Sancha Town, Xiaonan District, Xiaogan, Hubei, China (Mainland)

Mobile/Wechat/WhatsApp:+86 13692109735

VIEW MORE