Automatic suppository production line Pharmaceutical suppository filling and sealing line

- $20000.00 /set

- 1 set

- Pharmec Technologies Co., Ltd.

- Shanghai, China

- Ms jessie gao

PRODUCT DETAIL

| port: | Shanghai | Weight (kg): | 500 |

| application: | Chemical and pharmaceutical factories | place of origin; place of origin: | China Shanghai |

| Voltage: | Three-phase, 380V (customized) | Dimensions (L*W*H): | 2300 x 1200 x 1800 mm |

| Main selling point: | automatic | warranty period: | 2 years |

| Video external inspection: | if | Filler: | Synthetic fatty acid glycerides, glycerol, gels, etc. |

| Packaging Details: | Automatic suppository production line Medicine suppository filling and sealing line Packing: wooden case | product name: | Suppository Potting Sealing Packaging Machine |

| Warranty: | 1 year | Auto grade: | automatic |

| brand: | medicine | Mechanical test report: | if |

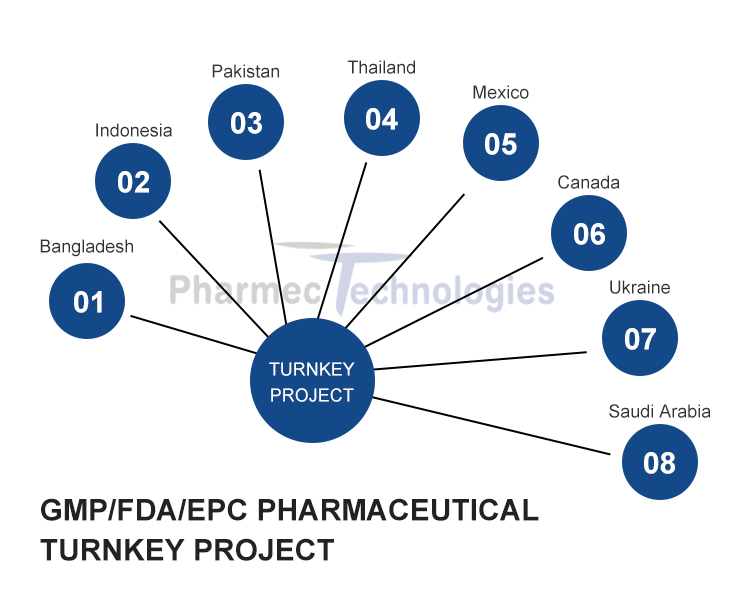

| Showroom location: | Canada, Saudi Arabia, Indonesia, Pakistan, Mexico, Russia, Thailand, Bangladesh, Ukraine, Uzbekistan | Packaging Materials: | PVC/PE (thickness: 0.15-0.18mm) |

| Single dose: | 0.5-5g | Health status: | new |

| Allowed doses: | <±2% | strength: | 4KW/5KW/7.5KW/9.5KW |

| Core Components Warranty: | 1 year | air pressure: | ≥0.7MPa |

| Core components: | PLC, engine, motor | usage: | Suppository filling and sealing machine |

| Supply capacity: | 10 sets of suppository filling sealing sealing packaging machines per month | Marketing Type: | normal product |

| payment terms: | L/C,Western Union,D/P,D/A,T/T,MoneyGram | Applicable industries: | Pharmaceutical factory, daily chemical industry |

Product Description

introduce

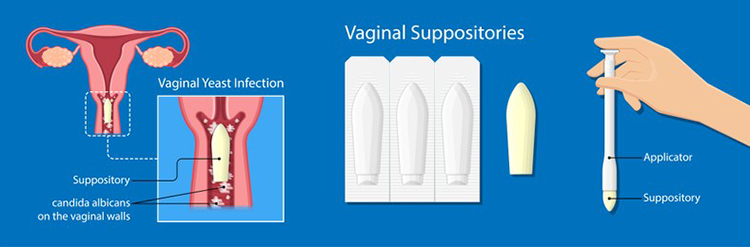

The automatic suppository production line is suitable for the production of bullet-shaped, torpedo-shaped, duckbill and other special-shaped shrapnel, which can meet the production of various shapes of suppositories. (Make molds according to samples or requirements.)

From the start of automatic capillary forming, to the liquid medicine filling station, reciprocating cooling and shaping (liquid to solid state), continuous sealing, batch number, finished product cutting (the number of cutting particles can be arbitrarily set on the touch screen, 1-10 free cutting)

technical parameter

The automatic suppository production line is suitable for the production of bullet-shaped, torpedo-shaped, duckbill and other special-shaped shrapnel, which can meet the production of various shapes of suppositories. (Make molds according to samples or requirements.)

From the start of automatic capillary forming, to the liquid medicine filling station, reciprocating cooling and shaping (liquid to solid state), continuous sealing, batch number, finished product cutting (the number of cutting particles can be arbitrarily set on the touch screen, 1-10 free cutting)

technical parameter

Name | laboratoryautomatic Suppository production line | continuous automatic Suppository production line | |||

Model | PT-1LS | PT-3LS | PT-7LS | ||

output | 1,000-2,000 pieces/hour 5,000-6,000 pieces/hour | 10,000-12,000 pieces/hour 15,000-18,000 pieces/hour 18,000-23,000 pieces/hour | |||

Mixing tank capacity | 20L/30L | 70L | |||

Air consumption/min | 1.5 m3/min | 1.6 m3/min | |||

total power | 4KW/5KW | 7.5KW/9.5KW | |||

machine weight | 500kg/1000kg | 2000kg/2500kg | |||

single dose | 0.5-5g | ||||

allowable dose | <±2% | ||||

wrap | PVC/PE Thickness: 0.15-0.18mm | ||||

work pressure | ≥0.7MPa | ||||

Water Consumption | 50kg/h (recycling) | ||||

Operating Voltage | Three-phase, 380V (customized) | ||||

Center distance | 17.4mm | ||||

shape | Various shapes such as bullets, torpedoes, duckbills, etc. | ||||

application | Synthetic fatty acid glycerides, glycerol, gelatin, polyethylene glycol, etc. | ||||

total measurement | PT-1LS L2300 x W1200 x H1800mm | PT-3LS L3578 x W1388 x H1828mm | PT-7LS L5839 x W1456 x H2115mm | ||

Material | Stainless steel |

custom made | accept |

Serve | foundry and foundry |

pack | Standard wooden packaging by sea |

If you want to know more,

please click here!

any problem,

Please feel free to contact us!

VIEW MORE

YOU MAY LIKE

Other Products

Related Searches

Blown Film Production Line

Auto Production Line Equipment

Magnesium Production Line

Pharmaceutical Filling Machines

Pickled And Oiled Steel Products

Fermented and renneted milk products

Fluid milk and milk products

Line and Dot Lasers

Whey and whey products

Home Textile Product Machine Parts