Pharmaceutical non-PVC soft bag physiological saline intravenous injection filling and sealing production line

- $95000.00 / 1 - 1 sets

$90000.00 / >=2 sets - 1 set

- Shanghai Marya Pharmaceutical Engineering & Project Co., Ltd.

- Shanghai, China

- Mr Andy Gao

| Core components: | PLC, bearings, gearboxes, motors, pressure vessels, gears, pumps | Production capacity: | 1000-8000BPH |

| Driver type: | electric | Package preview: | |

| Showroom location: | Bangladesh, Tajikistan | Weight (kg): | 6000 |

| usage: | liquid | Applicable industries: | Manufacturing plants, pharmaceuticals, medical |

| port: | Shanghai Port/Pharmaceutical non-PVC soft bag physiological saline intravenous injection filling and sealing production line | Voltage: | 380V 50Hz |

| payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram | Video outbound inspection: | if |

| Place of origin: | China | Filling capacity: | 50-3000ml |

| product name: | Soft bag IV liquid filling and sealing production line | Warranty: | 1 year |

| Supply capacity: | 50 sets per year | Mechanical test report: | if |

| Health status: | new | Marketing type: | 2020 new products |

| Main selling points: | High accuracy | Filling accuracy: | 1% |

| brand: | Maria | Core component warranty: | 1 year |

| Dimensions (length*width*height): | 8100*2000*2250mm | Packaging details: | Wooden packaging is suitable for shipping/medical non-PVC soft bag physiological saline intravenous injection filling and sealing production line |

| strength: | 10kW |

Pharmaceutical non-PVC soft bag physiological saline intravenous injection filling and sealing production line

Product Description

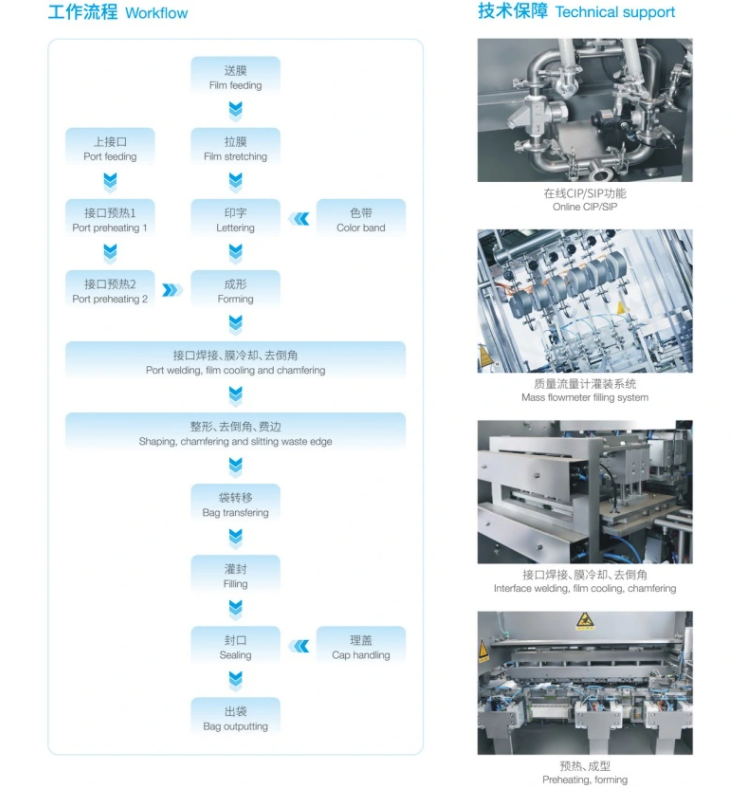

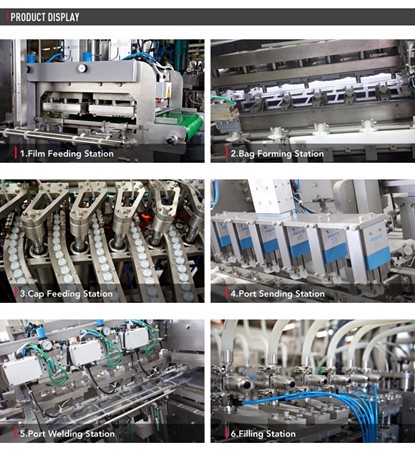

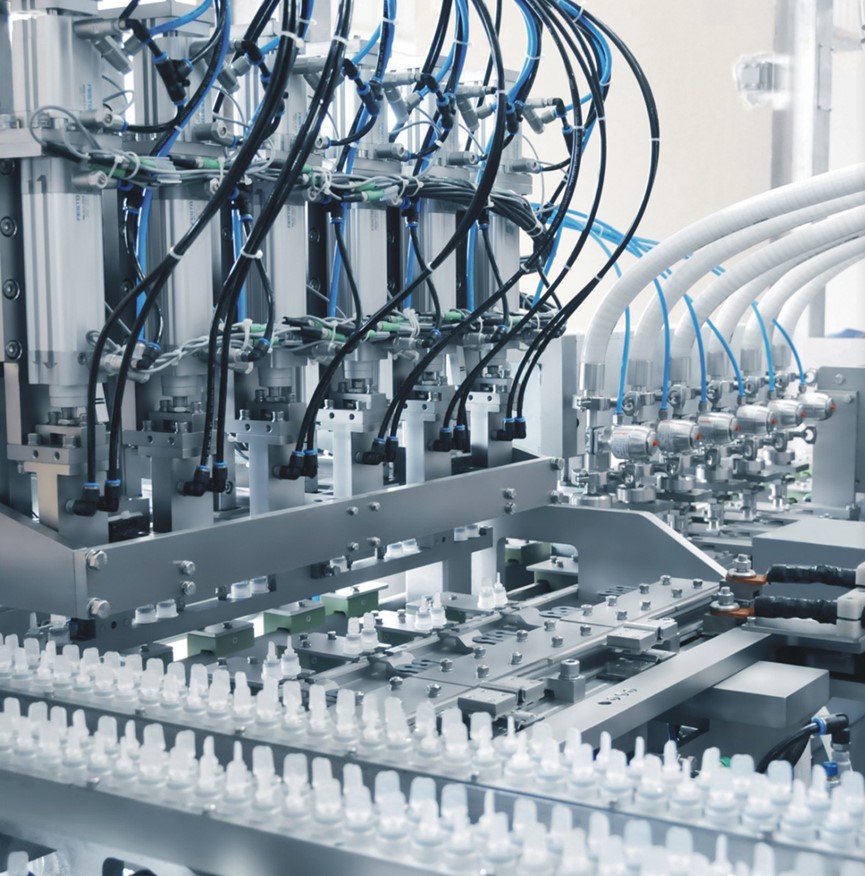

This machine is specially designed for pharmaceutical use as per GMP and CE guidelines. it is designed forForms, fills and seals two bags, each equipped with two SFC ports per cycle.

feature

(1)Precise temperature control

The temperature error can be controlled within ±0.5°C, and precision temperature control devices are used to ensure all qualificationsmembrane.

(2)Zero-tolerance manufacturing process

Ensure that the flatness and parallelism tolerances of the mold are within 1%mm, making replacement easy, adjustment-free, and delamination-free.

(3)Advanced industrial network

The system uses advanced communication networks to connect various industrial equipment to the network. Simplify hardwareConnect, reduce use errors, reduce the difficulty of use and maintenance, and reduce the number of uses

workers, streamlined equipment structure.

(4)Simple design

Simplicity is the ultimate sophistication.Ensure that the equipment is stable and efficient, while making the equipment structure the simplest and simplestOperation, commissioning and maintenance. Reduce the quality requirements for workers and reduce the number of workers.

Specification

|

Soft bag type |

CS2 type (2 bags/group) |

Comment |

|

Movie |

PP double roll multi-layer flat film (3 layers/5 layers) meets production requirements |

|

|

100ml/250ml |

2500 bags/hour |

The data must meet the following conditions: filling pressure 0.40Mpa/compressed air 0.75Mpa |

|

500ml |

2400 bags/hour |

|

|

filling pressure |

0.2Mpa-0.4Mpa |

|

|

filling temperature |

up to 55°C |

|

|

Filling accuracy |

+/- 1.0% |

|

|

Product connection |

50.5 standard clamp |

|

|

Online disinfection |

up to 125° C CIP |

|

|

Passing rate |

minute. 99.9% (based on qualified materials and error-free operation) |

|

|

Waste corner scrap rate |

99.99%, with independent waste corner collection tank |

|

|

strength |

Three-phase 380V 50Hz /CS2: Max. 10kW |

|

|

compressed air |

0.5Mpa~0.75Mpa, dry oil-free compressed air |

|

|

Cooling water |

None (heat dissipation module can be added according to customer requirements) |

|

|

nitrogen |

Can be increased according to customer requirements |

|

|

room temperature |

Recommendation: 20°C - 24°C |

|

|

Air humidity |

Recommended: 45%-65%/maximum 85% |

|

|

Temperature control accuracy |

Stable operation temperature control accuracy +/- 0.5°C start-stop control accuracy +/- 1.5°C |

|

|

Welding helmet error |

Maximum 0.1mm |

|

|

noise |

maximum. 75 decibels |

|

Packaging and shipping

Wooden packaging is suitable for shipping/medical non-PVC soft bag physiological saline intravenous injection filling and sealing production line

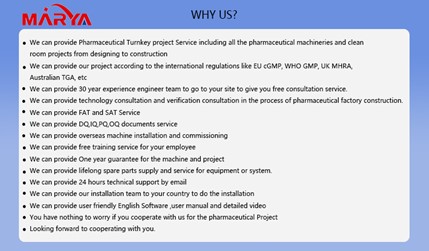

Company Profile

Shanghai Maria Pharmaceutical Engineering Project Co., Ltd. is a manufacturer specializing in pharmaceutical packaging machinery and clean room systems. We have 3 factories in Shanghai, Suzhou and Changsha. Our main products include BFS machine, soft bag filling and sealing machine, blister packaging machine (tablet/capsule/ampule/vial/syringe blister packaging machine), strip packaging machine, tablet counting machine, cartoning machine , ampoule filling machine, vial powder filling machine, dry granulator, etc. As a manufacturer, we can provide more favorable prices and better technical support and services than trading companies. We can design and manufacture machines according to customers' requirements, your satisfaction is our top priority. Our machines have been sold all over the country and exported to Southeast Asia, America, Europe, the Middle East, Africa and other countries and regions. Welcome to visit our factory.

FAQ

Look forward to working with you.

Online Contact

Please contact us online for more details

Phone: +86 173 5280 4920

We are waiting for you online 24 hours a day