Double-sided aluminum belt machine for health care capsules and herbal capsules

- $12500.00 / 1 - 4 units

$7500.00 / >=5 units - 1 unit

- LODHA INTERNATIONAL LLP

- Gujarat, India

- Mr Dhananjay Lodha

PRODUCT DETAIL

| Gearbox: | 14:1 ratio, universal mounting type (manufactured by "BONFIGLIOLI") | Core components: | PLC, engine, bearing, gearbox, motor, gear, pump |

| Weight (kg): | 450 | Supply capacity: | 10 units per month |

| Optional features: | No Fill Detection (NFD) System | port: | Navasheva |

| place of origin; place of origin: | Gujarat, India | Warranty: | 2 years |

| Health status: | new | usage: | Tablets and Capsules |

| Video external inspection: | if | Object: | Tablets Capsules and Lozenges |

| strength: | 50 Hz | maximum. Foil width: | 230 mm |

| Tool assembly: | Cam Operated Knife Assembly with Spring Loaded Brake Band. | BPA Unit (Batch Print Unit): | Fully automatic cassette type printing unit |

| Production output: | Up to 150,000 per hour | Packaging Preview: | |

| Core Components Warranty: | 1 year | product name: | Automatic Bar Packaging Machine |

| payment terms: | letter of credit, wire transfer | Showroom location: | Turkey, Saudi Arabia, India, UAE |

| After Warranty Service: | On-site maintenance and repair services | Certification: | ISO 9001:2015 and CE |

| Applicable industries: | Manufacturing plants, pharmaceutical plants, health products, herbal medicines | brand: | Loda |

| Main selling point: | competitive price | Packaging Details: | Export Worth Wooden Packaging |

| Mechanical test report: | if | Marketing Type: | New Products 2020 |

| Voltage: | 220 volts | Dimensions (L*W*H): | 1000(L) X 850(W) X 1850(H) mm |

Product Description

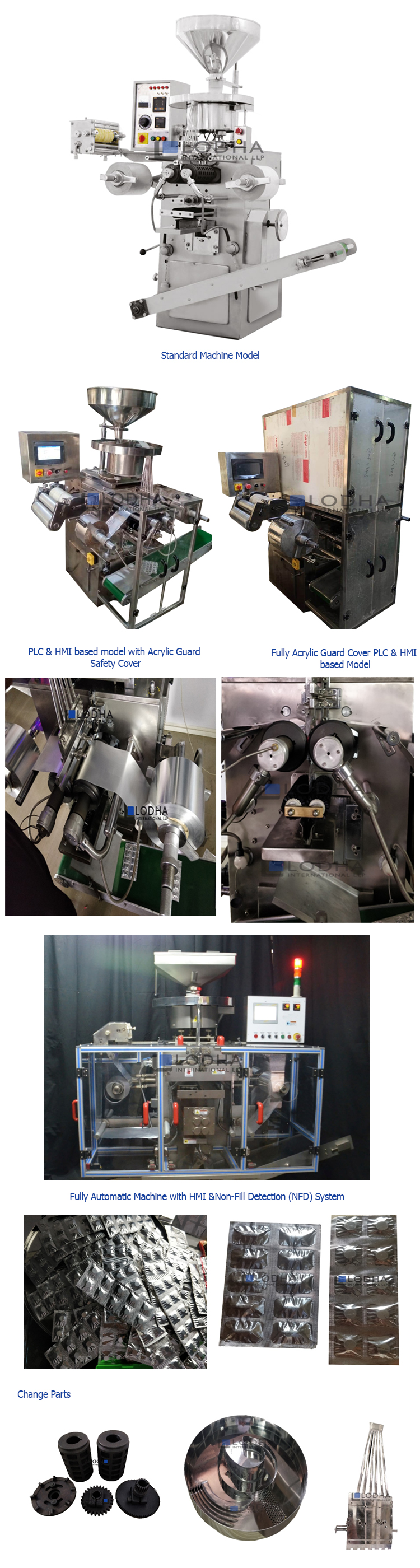

Double-sided aluminum belt machine for health care capsules and herbal capsules

- Supplement Capsule, Herbal Capsule Double-sided aluminum strip machines pack a wide variety of products into easy-to-dispensable strips, economical and fast. Its capacity is between 500 units/min to 2500 units/min. It handles a wide variety of products such as coated and uncoated tablets of any size/shape, hard and soft capsules, lozenges, confectionary products such as toffees, chewing gum, and electronic devices. Built on advanced technology to meet the requirements of the pharmaceutical packaging industry. Stick packers provide high speed and uninterrupted performance with low maintenance costs. They are ideal for high speed sealing of coated or uncoated tablets, capsules or lozenges of any shape or size in aluminum foil, polyethylene, cellophane or any other heat sealable material.

special function

- Automatic feeding, sealing, slitting and slitting are carried out at the same time.

- Therefore, it is highly efficient, which means lower production costs due to lower labor costs.

- Models from 2 rails to 10 rails,

- Seal width from min. 40mm to max. 310mm.

- Remove conveyor belts of different sizes and convey the strips to the inspection and packing station.

- The machine is suitable for different heat sealing packaging laminates.

- Motors for 415 V/ 380 V/ 3 PH/ 50 CS/ AC power supply.

- All contact parts are SS316.

- Compliant with cGMP.

- Replacement parts can be easily replaced.

special accessories

- Simultaneous batch encoding

- print register control

- horizontal perforation

- vertical perforation

- zigzag cut

- No Fill Detection (NFD) System

- programmable logic controller

- Multi-product feed

- Use preform rolls

- Security

- Slotted for easy tearing

- Batch encoding with metal types

- irregularly shaped pockets

- engraving on the strip

- Use of inkjet printing

- 5/7 tablets/capsule bar

flow chart:

- Vibrator: Delivers the product to the chute through the supply tablet.

- Chute: This device clamps various parts and centers them so that they enter the sealing roller.

- Sealing roller: adopting precise temperature control device, the temperature of sealing roller can be maintained stably.

- Slitting: The number and position of slitting columns can be easily adjusted.

- Brushes: Tighten the strips to ensure a perfect seal and cut.

- Cutter: The number of rows of the cutter can be adjusted according to your needs

Specification

| Model | Listing 2 | Listing 4 | Listing 6 | Listing 8 | Listing 10 |

| Output - Tablets/hour | 15000 to 35000 | 35000 to 48000 | 48000 to 72000 | 60000 to 96000 | 75000 to 1,20,000 |

| Stripping output/min. | 250 to 600 | 600-1200 | 1200- 1800 | 1800-2500 | 2250 – 3125 |

| foil | Aluminum paper/any heat sealing material | ||||

| Foil width (max) | 90 mm | 140 mm | 210 mm | 260 mm | 310 mm |

| Foil roll diameter (max mm) | 400 | 400 | 300 | 300 | 300 |

| powder | 0.5 hp | 1 hp | 1 hp | 2 hp | 2 hp |

| heater | 1 kW | 1.5kW | 2kW | 3kW | 3kW |

| feeding arrangement | Automatic vibration | ||||

| cut | Built-in arrangement | ||||

| Temperature Controller | Digital Automatic Temperature Controller | ||||

| Slitting unit | Built-in arrangement | ||||

| in all dimensions | 1100 x 1050 x 1650 mm | 1100 x 1050 x 1650 mm | 1100 x 1150 x 1650 mm | 1100 x 1150 x 1650 mm | 1200 x 1200 x 1800 mm |

| net weight | 380 kg. | 410 kg. | 450 kg. | 490 kg. | 550 kg. |

VIEW MORE

YOU MAY LIKE