CNC stainless steel galvanized sheet sheet bending machine bending machine

- $842.63 /set

- 1 set

- Jiangmen Zhuosheng Machinery Co., Ltd.

- Guangdong, China

- Mr Taylor Shu

PRODUCT DETAIL

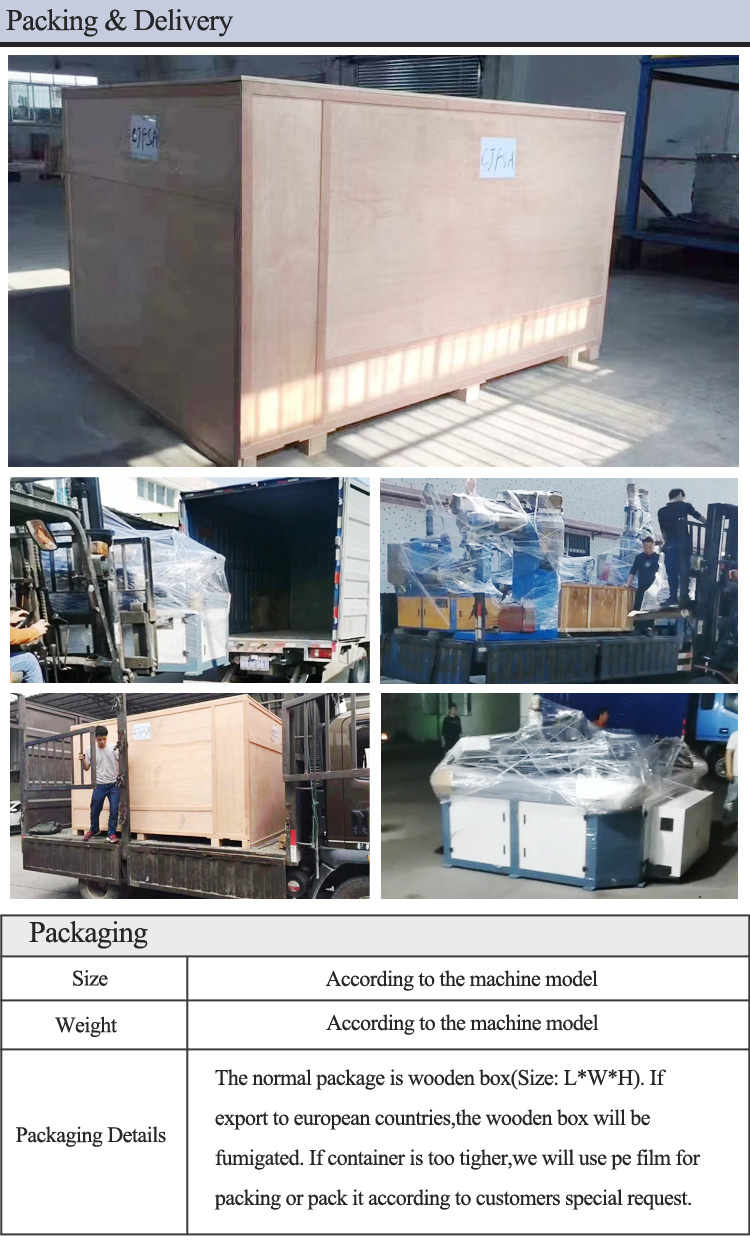

| Packaging Details: | Standard export packaging | Weight (kg): | 2600kg |

| strength: | 380V three-phase four-wire | Extra Services: | Automatic loading and unloading |

| Showroom location: | not any | brand: | Zhuosheng |

| place of origin; place of origin: | Guangdong, China | Warranty: | 1 year |

| automation: | automatic | Marketing Type: | normal product |

| Core components: | PLC, engine, bearing, gearbox, motor | Rolling speed (m/min): | 1 - 6 |

| Mechanical test report: | if | payment terms: | L/C,Western Union,D/P,D/A,T/T,MoneyGram |

| Applicable industries: | Building material stores, mechanical repair shops, food and beverage factories, construction works | Packaging Preview: | |

| Productivity: | 100-800 pieces/hour | After-sales service provided: | Free spare parts, online support, video technical support |

| Local service location: | not any | Core Components Warranty: | 1 year |

| year: | new | maximum. Working Length (mm): | 1000 mm |

| After Warranty Service: | Video technical support, online support | Supply capacity: | 300 sets per month |

| port: | Shenzhen Foshan Guangzhou | Main selling point: | automatic |

| Equipment quality: | 2.6T | Material/Metal Finishing: | Aluminum, carbon steel, alloy, stainless steel |

| Motor power (kW): | 10.5kW | Disc diameter: | 2000mm |

| Video external inspection: | if | Coil Length: | 1000mm |

| Type of machine: | Rolling machine | Equipment Specifications: | 2000x2500x2200(mm) |

| Number of rollers: | 2 | maximum. Plate thickness (mm): | 2 mm |

| Certification: | ce | Health status: | new |

| main motor power: | 6.2KW |

Product Description

Manufacturers produce automatic loading and unloading platform automatic CNC bending machine 4 rounding machine

Mechanical parameters:

thing | value |

Materials/Metal Processing | Aluminum, carbon steel, alloy, stainless steel |

maximum. Working length (mm) | 1000mm |

maximum. Plate thickness (mm) | 2mm |

Video checkout | if |

Mechanical Test Report | if |

Marketing Type | normal product |

Core Components Warranty | 1 year |

core components | PLC, engine, bearing, gearbox, motor |

Number of rollers | 2 |

Rolling speed (m/min) | 6 |

Health status | new |

place of origin; place of origin | China |

Guangdong | |

brand | Zhuosheng |

automation | automatic |

extra service | Automatic loading and unloading |

Certification | ce |

year | new |

Weight (kg) | 2600KG |

Motor power (kw) | 10.5kW |

type of machine | Rolling machine |

main selling point | automatic |

Warranty | 1 year |

Free spare parts, online support, video technical support | |

after-warranty service | Video technical support, online support |

Applicable industries | Building material stores, machinery repair shops, food and beverage factories, construction works |

local service location | not any |

Showroom Location | not any |

strength | 380V three-phase four-wire |

Coil Specifications | 1000mm |

Coil length | 1000mm |

main motor power | 6.2KW |

Productivity | 100-800 pieces/hour |

Equipment Specifications | 2000x2500x2200(mm) |

Equipment quality | 2.6T |

Features of hydraulic automatic winder:

Our company not only produces automatic polishing machine series, but also produces and develops metal forming machines. We produce various types of automatic winding machines for forming machinery. Models are mainly customized according to length. The length specifications are mainly 200400600. The 800.1000.1200.1500 model can be customized according to your own requirements in terms of tapered coils.

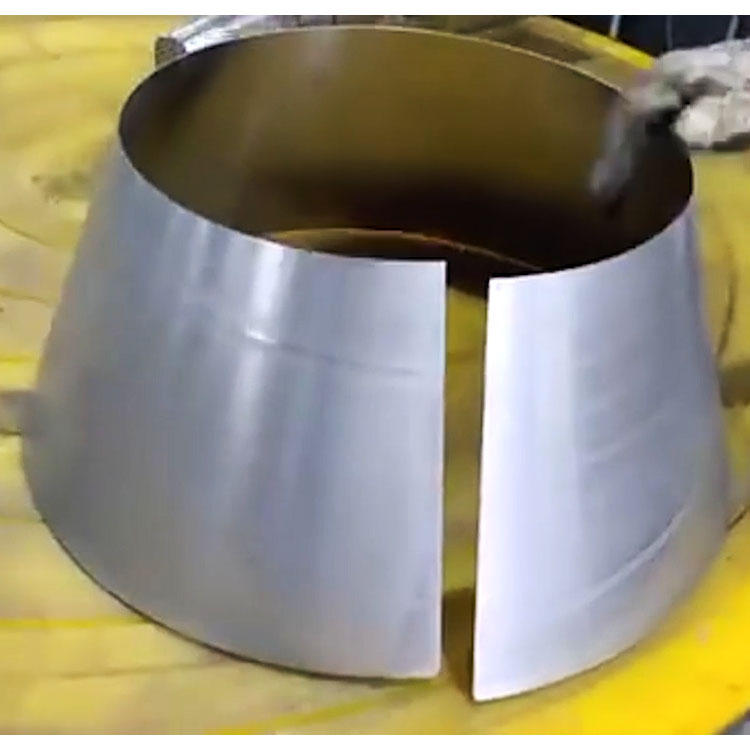

1. Large taper winding machine The automatic winding machine is mainly aimed at the large taper requirements of the workpiece around the plate, with high efficiency. It can complete a workpiece in 8-20 seconds, and the taper size is different from its model.

2-taper winding machine The automatic winding machine is easy to operate, only needs simple training to start the job, and one person can operate it.

3. The roundness of the taper coil product of this machine is high, depending on the material, and it can generally be controlled within 30-50 wires

4. Non-standard bending machines can be customized according to customer workpiece requirements, such as: large diameter, large taper bending machines, heavy duty bending machines, etc.

5. The equipment is easy to operate, easy to maintain, easy to learn and easy to work.

1. Large taper winding machine The automatic winding machine is mainly aimed at the large taper requirements of the workpiece around the plate, with high efficiency. It can complete a workpiece in 8-20 seconds, and the taper size is different from its model.

2-taper winding machine The automatic winding machine is easy to operate, only needs simple training to start the job, and one person can operate it.

3. The roundness of the taper coil product of this machine is high, depending on the material, and it can generally be controlled within 30-50 wires

4. Non-standard bending machines can be customized according to customer workpiece requirements, such as: large diameter, large taper bending machines, heavy duty bending machines, etc.

5. The equipment is easy to operate, easy to maintain, easy to learn and easy to work.

pre-sale service

*Inquiry and technical support

* Technical documents

All labels on machine and layout drawings, electrical diagrams, operating manuals are in English. Seller should put all

Provide the buyer with the necessary documents from the third week after project execution. All paper documents should also be shipped

with the machine.

* Quantity and quality assurance

One. Inconsistency in quantity/quality to destination port during transportation: If the quality/quantity to destination does not match

At the port of shipment, the buyer should file a claim within 30 days after the goods arrive at the port of destination. This

The seller is not responsible for the inconsistency of the goods caused by the shipping company and other transportation agencies

and/or post office.

b.Shelf life and after-sales service: 12 months from the date of the bill of lading. During this warranty period, the seller will

If the quality does not match due to our reasons, spare parts will be provided free of charge. If the failure is caused by your improper operation, the seller will provide the buyer with spare parts at cost.

* View our factory.

* Technical documents

All labels on machine and layout drawings, electrical diagrams, operating manuals are in English. Seller should put all

Provide the buyer with the necessary documents from the third week after project execution. All paper documents should also be shipped

with the machine.

* Quantity and quality assurance

One. Inconsistency in quantity/quality to destination port during transportation: If the quality/quantity to destination does not match

At the port of shipment, the buyer should file a claim within 30 days after the goods arrive at the port of destination. This

The seller is not responsible for the inconsistency of the goods caused by the shipping company and other transportation agencies

and/or post office.

b.Shelf life and after-sales service: 12 months from the date of the bill of lading. During this warranty period, the seller will

If the quality does not match due to our reasons, spare parts will be provided free of charge. If the failure is caused by your improper operation, the seller will provide the buyer with spare parts at cost.

* View our factory.

After-sales service

* Arrange inspection, installation and testing work

1.After all machines are delivered to the customer's factory; the buyer is responsible for all preparations such as electricity

Supply, water supply, labor and cranes, etc.

2.The buyer will prepare the visa application for their engineer who will guide the machine installation and

Tested at buyer's factory.

3.If the visa application is approved, the buyer will purchase round-trip air tickets for the engineer. The buyer is also responsible for visa procedures, meals, accommodation and allowances of USD 80 per engineer per day.

4.Engineers will provide free training sessions for workers at the buyer's facility.

Supply, water supply, labor and cranes, etc.

2.The buyer will prepare the visa application for their engineer who will guide the machine installation and

Tested at buyer's factory.

3.If the visa application is approved, the buyer will purchase round-trip air tickets for the engineer. The buyer is also responsible for visa procedures, meals, accommodation and allowances of USD 80 per engineer per day.

4.Engineers will provide free training sessions for workers at the buyer's facility.

*The seller will charge the buyer the cost price of spare parts for more than one year and provide long-term technical guidance.

* 1 year quality warranty

Contact us for the latest prices! ! ! !

VIEW MORE

YOU MAY LIKE

Other Products

-

Woodworking mortise square eye small multifunctional lock wood tenoning machine$212.05 - $241.07 / set

Woodworking mortise square eye small multifunctional lock wood tenoning machine$212.05 - $241.07 / set -

One-hand operation multi-function high-power one-time forming automatic hand-held cutting and slotting machine$135.60 / set

One-hand operation multi-function high-power one-time forming automatic hand-held cutting and slotting machine$135.60 / set -

Rolling Easy Operation Tube Bender Manual Hydraulic Tube Bender Tube Bender$81.00 / set

Rolling Easy Operation Tube Bender Manual Hydraulic Tube Bender Tube Bender$81.00 / set -

Professional custom high-precision high-performance punching, trimming, hemming, multi-functional automatic flanging machine$680.00 / set

Professional custom high-precision high-performance punching, trimming, hemming, multi-functional automatic flanging machine$680.00 / set -

Aluminum edge flat light equipment simple steel bar groove bending machine$1251.00 / set

Aluminum edge flat light equipment simple steel bar groove bending machine$1251.00 / set