Manufacturer Cnc 4 roller Plate Rolling Machine For Pressure Vessel

- $28570.00 / 2 - 4 sets

$26400.00 / >=5 sets - 2 sets

- Nantong Jobest Machinery Technology Co., Ltd.

- Jiangsu, China

- Mr Jack Wang

| Discharge unload: | Automatic hydraulic oil pump control; | No. of Roller: | 4; |

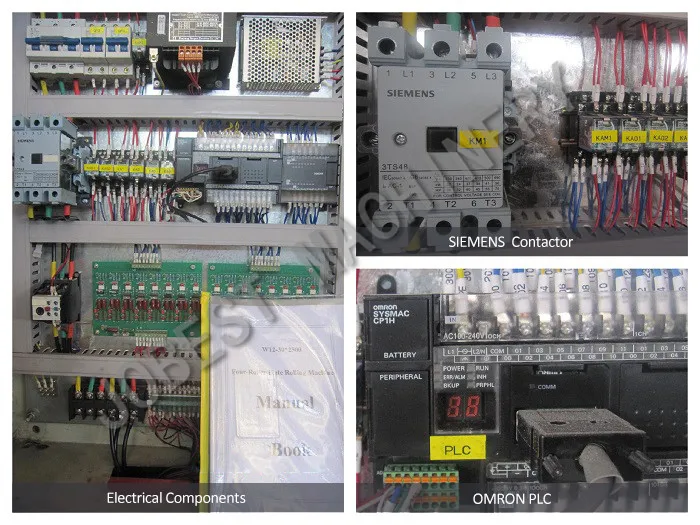

| Elctric components: | SIEMENS; | Rolling machine manufacture: | 4 roller hydrualic bend rolling machine; |

| Weight: | According to machine model; | Applicable Industries: | Manufacturing Plant; |

| Control system: | CNC OMRON JAPAN; | Weight (KG): | 15000 KG; |

| Rolling Speed (m/min): | 3 - 4; | Sealing element: | Valqua; |

| Supply Ability: | 60 Sets per Month Hydraulic rolling machine; | Max. Plate Thickness (mm): | 200 mm; |

| Material / Metal Processed: | Aluminum,Carbon steel,Stainless Steel; | Extra Services: | End Forming; |

| After-sales Service Provided: | Free spare parts,Field installation, commissioning and training,Field maintenance and repair service,Online support,Video technical support; | Motor Power (kw): | 18.5 KWkw; |

| Packaging Detail: | Covered by plastic film and fixed by steel wire in containers, well protected during shipping; | Certification: | ISO 9001:2000; |

| Machine Type: | Roller-Bending Machine; | Port: | Shanghai; |

| Automation: | Automatic; | Roller details: | 42CrMo Heat treatment at HB260~300; |

| Payment Terms: | L/C,T/T,Western Union; | Brand Name: | JOBEST; |

| Keywords: | 4 roller plate rolling machine; | Warranty: | 2 years; |

| Condition: | New; | Bending machine application: | Steel Sheet Rolling Machine; |

| Max. Working Length (mm): | 10000 mm; | After Warranty Service: | Video technical support; |

| Place of Origin: | Jiangsu, China; | Local Service Location: | None; |

| Hydraulic valve: | YUKEN; | Showroom Location: | None; |

| Key Selling Points: | Competitive Price; |

Manufacturer Cnc 4 roller Plate Rolling Machine For Pressure Vessel

Shearing machine Press Brake Machine Section Bending Machine

W12-series CNC Four-roller bending machine with international advanced technology, controlled by PLC programmable numerically, all hydraulic driving, it's a heavy duty CNC rolling machine which can come true automatic bending, also it's the nesy equipment for bending multi section curved, square, round, conical and other special shape working piece.

Optional Special Device

- Top support device

- Lower roller auxiliary drive

- Side support device

- Cone device

- Feeding roll-table

- Roller shaft grinding/ chrome encapsulating

Design Characteristics

- Numerically control, roll forming by one time.

- Touch screen support visual input, edit, save 500 sets data.

- EPS electronic balance system, keep the rollers running parallel within 0.15mm.

- Support man-machine dialog, fault self diagnoise, operation error intelligent judgment.

- Drum shaped roller shaft, bending roundness, high straightness.

- All hydraulic driving, both side rollers doing line running inner the guide.

- The smaller central distance between two side rollers, come out the most correct bending presicion.

- Thickner whole-frame, meet the need of middle & larger bending.

- Machine frame integral quenching eliminate stress, never deformation.

- The roller shaft i whole forgin by quenching and tempering, hardening treatment process.

- Two control mode: manually and automatically.

Manufacturer Cnc 4 roller Plate Rolling Machine For Pressure Vessel

Manufacturer Cnc 4 roller Plate Rolling Machine For Pressure Vessel

Manufacturer Cnc 4 roller Plate Rolling Machine For Pressure Vessel

| Model | Max.Roll Thickness | Max.RolLwidth | Upper roller diamater | Side Roller Diemater | Motor |

mm | mm | mm | mm | Kw | |

| W12-4x1500 | 4 | 1500 | 140 | 120 | 2.2 |

| W12-6x2000 | 6 | 2000 | 190 | 170 | 3 |

| W12-6x2500 | 6 | 2500 | 190 | 170 | 3 |

| W12-8x2500 | 6 | 2500 | 210 | 190 | 7.5 |

| W12-12x2000 | 12 | 2000 | 270 | 250 | 11 |

| W12-12x3000 | 12 | 3000 | 300 | 270 | 11 |

| W12-16x2500 | 16 | 2500 | 300 | 270 | 11 |

| W12-16x4000 | 16 | 4000 | 390 | 360 | 18 |

| W12-20x2000 | 20 | 2000 | 330 | 300 | 11 |

| W12-20x3000 | 20 | 3000 | 360 | 330 | 15 |

| W12-25x2500 | 25 | 2500 | 390 | 360 | 18.5 |

| W12-30X2500 | 30 | 2500 | 390 | 360 | 18.5 |

| W12-30x3000 | 30 | 3000 | 430 | 390 | 22 |

| W12-35x3000 | 35 | 3000 | 460 | 420 | 30 |

| W12-45x2500 | 45 | 2500 | 460 | 420 | 30 |

| W12-45x3000 | 45 | 3000 | 510 | 460 | 37 |

| W12-50x2500 | 50 | 2500 | 510 | 460 | 45 |

| W12-50X3000 | 50 | 3000 | 540 | 500 | 45 |

| W12-65x3000 | 65 | 3000 | 650 | 550 | 55 |

| W12-85x3000 | 85 | 3000 | 760 | 680 | 75 |

Manufacturer Cnc 4 roller Plate Rolling Machine For Pressure Vessel

Nantong Jobest Machinery Technology Co., Ltd founed in 1998, is a leader of Metal Forging Machine. Such as Shearing Machine, Press Brake Machine, Plate Rolling Machine, Profile Bending Machine, Hydraulic Press Machine, Notching Mahine, Iron Worker Machine, Laser Cutting Machine, etc. Meanwhile we're familiar with kinds of Processing Machines to help our clients choose the most suitable machine on the best quality by economically.

CERTIFICATE

WORKSHOP

PROCESSING EQUIPMENTS

CLIENTS

Manufacturer Cnc 4 roller Plate Rolling Machine For Pressure Vessel

Other Products

-

Pipe End Forming Machine Hydraulic Pipe End Forming Machine SG-60 80 100 120$1950.00 - $2000.00 / set

Pipe End Forming Machine Hydraulic Pipe End Forming Machine SG-60 80 100 120$1950.00 - $2000.00 / set -

Factory price sheet metal stainless steel CNC hydraulic V-groove machine V-groove cutting machine CNC V-groove cutting machine$4800.00 - $5000.00 / set

Factory price sheet metal stainless steel CNC hydraulic V-groove machine V-groove cutting machine CNC V-groove cutting machine$4800.00 - $5000.00 / set