Factory price sheet metal stainless steel CNC hydraulic V-groove machine V-groove cutting machine CNC V-groove cutting machine

- $5000.00 / 1 - 2 sets

$4800.00 / >=3 sets - 1 set

- Nantong Jobest Machinery Technology Co., Ltd.

- Jiangsu, China

- Mr Jack Wang

| maximum. Slotting distance: | 8mm | Showroom location: | not any |

| Applicable industries: | Mechanical Repair Shop, Manufacturing Plant | Air pressure: | 6-8Mpa |

| Position Accuracy: | ±0.01mm | Voltage: | According to customer requirements |

| Control axis: | X+Y+Z (3 axes) | Health status: | new |

| After-sales service provided: | On-site installation and commissioning training, on-site maintenance and repair services, online support, free spare parts, video technical support | Slotting Thickness: | 0.5-6mm |

| Knife LR Resolution: | ±0.001mm | Main selling point: | competitive price |

| product name: | V-groove machine | Supply capacity: | Monthly production of 1000 CNC stainless steel V-groove cutting machines |

| Packaging Details: | CNC Stainless Steel V-Groove Cutter - Covered with plastic film and secured with steel wire in a container, well protected during shipping. | maximum. Grooving speed: | 65m/min |

| Certification: | EU standard | place of origin; place of origin: | Jiangsu, China |

| payment terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram | Warranty: | 2 years |

| Knife UD Resolution: | ±0.001mm | After Warranty Service: | Video technical support |

| Power (kW): | 5.5 | rated power: | 5.5KW |

| port: | Port of Shanghai, China | Local service location: | not any |

| brand: | Jobs | Weight (kg): | 8500 |

Factory price sheet metal stainless steel CNC hydraulic V-groove machine V-groove cutting machine CNC V-groove cutting machine

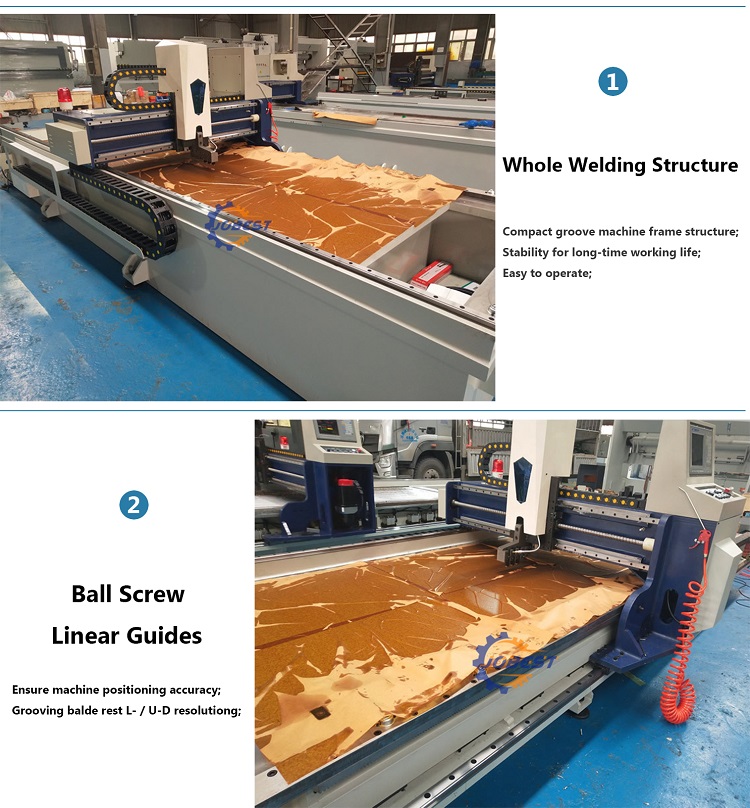

This equipment is a fully CNC V-grooving machine for sheet metal. Using advanced numerical control system and innovative design, it has the advantages of high machining accuracy, simple operation, no noise, no vibration and so on. It is widely used in the processing of irregular grooves such as V-shaped grooves and U-shaped grooves in sheet metal (including special plates such as stainless steel, aluminum plate, aluminum plate, copper, iron, plastic, wood, acrylic plate, etc.). It is suitable for V-groove processing before sheet metal bending.

CNC Stainless Steel V-Groove Cutting Machine

| Model | maximum. Slot thickness(mm) | minute. Groove thickness (mm) | slot speed (m/min) | Knife LR Resolution (mm) | Knife UD Resolution (mm) | Position accuracy (mm) | air pressure (Marine Reserve) | aspect (LxWxH) (mm) |

| 1220x2500 | 6 | 0.5 | 65 | ±0.001 | ±0.001 | ±0.01 | 6-8 | 4650x2300x1680 |

| 1220x3200 | 6 | 0.5 | 65 | ±0.001 | ±0.001 | ±0.01 | 6-8 | 5500x2300x1680 |

| 1220x4000 | 6 | 0.5 | 65 | ±0.001 | ±0.001 | ±0.01 | 6-8 | 6000x2300x1680 |

| 1220x5000 | 6 | 0.5 | 65 | ±0.001 | ±0.001 | ±0.01 | 6-8 | 7500x2300x1680 |

| 1220x6000 | 6 | 0.5 | 65 | ±0.001 | ±0.001 | ±0.01 | 6-8 | 8500x2300x1680 |

| 1500x4000 | 6 | 0.5 | 45 | ±0.001 | ±0.001 | ±0.01 | 6-8 | 6000x2550x1700 |

| 1500x6000 | 6 | 0.5 | 45 | ±0.001 | ±0.001 | ±0.01 | 6-8 | 8500x2550x1700 |

application

-The body is all steel plate welded structure, tempering and aging, and the deformation is small;

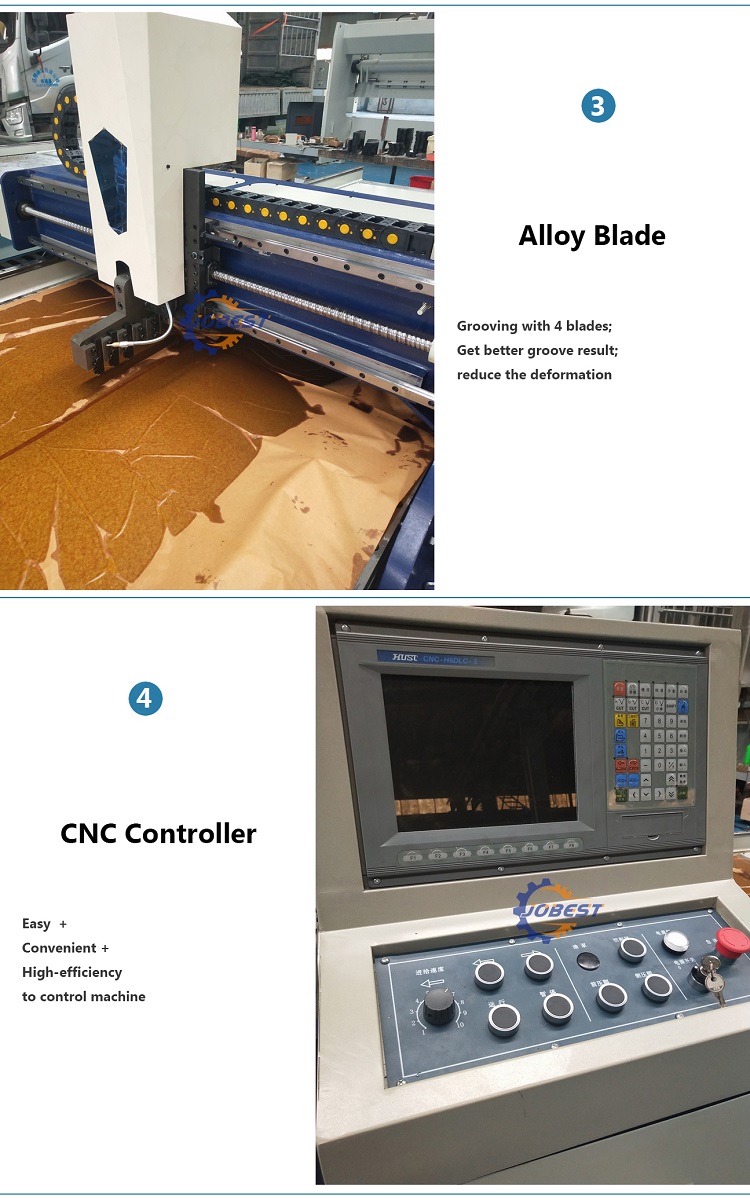

- Using CNC (Numerical Control) device, automatic processing;

- Adopt air pressure device, fully automatic clamping and releasing;

- The bottom surface of the planer can be adjusted after wear and tear to improve the service life of the whole machine;

- Using five planers to work together, the planing efficiency is high;

- There is a detachable bracket in front of the worktable, which is convenient for processing long workpieces;

- Full servo motor, accurate positioning and high precision;

- All operating systems of the whole machine are precisely combined with electro-pneumatics, which are simple in operation, flexible in action, high in efficiency, low in noise and free from environmental pollution.

CNC Stainless Steel V-Groove Cutting Machine

- Frames and beams are box-shaped. All-steel welding is optimized by finite element design, tempering eliminates residual stress, and the overall rigidity is good and the precision is good.

- The front and rear (Y1 axis) movement of the tool post, the up and down (Z axis) movement, and the front and rear (Y2 axis) movement of the end pressing material are all driven by CNC system, AC servo motor, ball screw control driving, high control precision, accurate positioning, etc. .

- The left and right (X-axis) movement of the beam is driven by an AC variable frequency speed regulating motor, and the helical gear and rack and pinion transmission have the characteristics of high speed and strong bearing capacity.

- The pneumatic pressing system can automatically press the workpiece side and the feed side according to different thicknesses, which is one of the effective measures to ensure the machining accuracy and repeatability.

- Compressed air blowing cooling system not only prevents chips from scratching the workpiece surface, but also improves tool life by cooling the tool.

Other Products

-

Pipe End Forming Machine Hydraulic Pipe End Forming Machine SG-60 80 100 120$1950.00 - $2000.00 / set

Pipe End Forming Machine Hydraulic Pipe End Forming Machine SG-60 80 100 120$1950.00 - $2000.00 / set -

Manufacturer Cnc 4 roller Plate Rolling Machine For Pressure Vessel$26400.00 - $28570.00 / set

Manufacturer Cnc 4 roller Plate Rolling Machine For Pressure Vessel$26400.00 - $28570.00 / set