Ceramic round chamber filter press price preferential automatic customized filter press

- $980.00 / 1 - 49 sets

$580.00 / 50 - 199 sets

$350.00 / >=200 sets - 1 set

- Shenzhen Hongfa Environmental Protection Equipment Co., Ltd.

- Guangdong, China

- Ms Ada Xu

PRODUCT DETAIL

| Voltage: | 380V/400V/415V | Filter plate material: | Highly enhanced PP |

| Key words: | Wastewater sludge dewatering equipment filter press | Core components: | engine, motor |

| Automatic level: | manual | product name: | Chamber automatic pressurization manual pull filter press |

| Warranty: | 1 year | Gross weight per piece: | 30.000 kg |

| Video outbound inspection: | if | Package preview: | |

| Dimensions (L*W*H): | 6200*1150*1300mm | control: | hydraulic workstation |

| Marketing Type: | 2020 New Products | Single pack size: | 50X50X60 cm |

| strength: | 4 kW | weight: | 4600 kg |

| brand: | Shen Hongfa | Mechanical test report: | if |

| Showroom location: | not any | color: | client needs |

| Chamber volume: | 880L | Packaging Details: | Airworthy packaging for filter press |

| describe: | Solid-liquid separation filter | Origin: | Shenzhen |

| Core component warranty: | 1 year | Sales unit: | single product |

| usage: | environmental protection | Filter area: | 70 square meters |

| Health status: | new | Applicable industries: | Hotels, Clothing Stores, Manufacturing Factories, Printing Shops, Construction Works, Food and Beverage Stores, Others |

| Filter plate size: | 800*800mm |

Why choose our filter press?

1. We provide filter presses in various sizes to meet your needs. From our large 2000mm to 150mm laboratory filter presses.

2. The filter press can also be equipped with automatic cloth washing device, drip tray, pneumatic diaphragm pump, filter plate, oscillation system, etc.

3. Together with the filter press, we can provide a complete filter press dehydration equipment, including

Thickener and all necessary auxiliary equipmentVegetable Feed Pump,compressor, conveyors and

Even special chemical resistant coatings.

Every filter press we offer is designed to provide you with sustainable productivity.

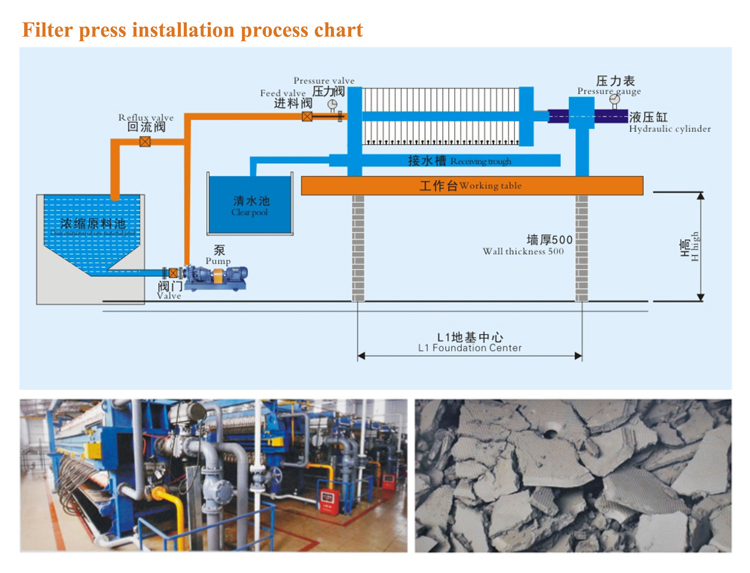

Filter press installation flow chart

Technical Parameters

Filtration area (㎡) | Filter plate thickness (mm) | Sheet size (mm) | Filter cake thickness (mm) | Chambers (unit) | Total volume (L) | Working pressure (Mpa) | Motor power(kW) | Weight (kg) | Dimensions (L*W*H)(mm) |

60 | 72/70 | 1000 | 40 | 38 | 1190 | ≤2.0 | 4 | 7670 | 6010*1560*1360 |

70 | 72/70 | 1000 | 40 | 44 | 1380 | ≤2.0 | 4 | 8090 | 6440*1560*1360 |

80 | 72/70 | 1000 | 40 | 50 | 1560 | ≤2.0 | 4 | 5810 | 6870*1560*1360 |

90 | 72/70 | 1000 | 40 | 56 | 1750 | ≤2.0 | 4 | 8930 | 7300*1560*1360 |

100 | 72/70 | 1000 | 40 | 62 | 1940 | ≤2.0 | 4 | 9350 | 7740*1560*1360 |

Application field

Filter presses are suitable for almost all types of slurries such as:Ceramic industry, stone industry, glass industry, mining industry, coal washing industry, sand washing industry, paper pulling industry, food industry,Chemical and pharmaceutical industry, electroplating industry, Textile printing and dyeing, leather industry, municipal pulp, etc.

feature

Low residual moisture, high capture rate;

Low energy consumption, reliable and automatic operation;

Rugged design, suitable for harsh working conditions;

Rugged design, suitable for harsh working conditions;

Long service life, high operational availability, and free access to the plate pack;

Special design for corrosive media;

Modular design, customer-oriented process solutions.

Special design for corrosive media;

Modular design, customer-oriented process solutions.

VIEW MORE

YOU MAY LIKE