High pressure hydraulic mud filter press

- $1500.00 / 1 - 98 sets

$1000.00 / >=99 sets - 1 set

- Zhengzhou Toper Industrial Equipment Co., Ltd.

- Henan, China

- Mr Rocky Pan

| Dimensions (L*W*H): | 3610*1150*1100mm | Video external inspection: | if |

| Mechanical test report: | if | Packaging Details: | export wooden packaging |

| describe: | solid-liquid separation | After-sales service provided: | Provide overseas service center |

| Board size (mm): | 630*630 | Filtration area (㎡): | 30 |

| payment terms: | L/C,Western Union,D/P,D/A,T/T,MoneyGram | Marketing Type: | normal product |

| weight: | 5000 kg | strength: | 2.2kW |

| Core parts warranty: | 1 year | Health status: | new |

| brand: | Jacket | Packaging Preview: | |

| Voltage: | 380V | Chamber volume (L): | 452 |

| Core components: | engine | Auto grade: | automatic |

| Cake Thickness(mm): | 25 | Applicable industries: | Hotels, Clothing Stores, Building Materials Stores, Manufacturing Plants, Machinery Repair Stores, Food and Beverage Plants, Farms, Restaurants, Home Use, Retail, Food Stores, Printing Stores, Construction Works, Energy and Mining, Food and Beverage Stores, Advertising Agencies |

| License Plate Number (PCS): | 37 | Filtration pressure (MPa): | 0.6 |

| place of origin; place of origin: | Henan, China | application: | Petrochemical, metallurgy, petroleum, ceramics |

| Warranty: | 12 months | Showroom location: | Russia, Malaysia |

High pressure hydraulic mud filter press

working principle:

When the pump pressure is delivered, the feed liquid to be filtered enters the filter chamber, and the solid and liquid are separated through the filter medium. A filter cake is formed on the filter cloth until the filter chamber is filled to form a filter cake. The filtrate flows through the filter cloth and filter plate groove along the product liquid into the channel, and is concentrated and discharged. After filtration, the filter residue can be washed with washing water. After washing, compressed air is sometimes introduced to remove the remaining washing liquid. After filtering, open the filter press, take out the filter cake (the filter cake is stored between two adjacent filter plates), wipe it with a cloth, and keep the plate filter and enter the next working cycle.

The surface of the filter plate is a concave-convex platform to support the filter cloth. The center of the holes and corners of the filter plate, when assembled, form a complete channel for entering the suspension, washing water and leading out the filtrate. There are brackets with handles on both sides of the filter plate beam to compress the filter plate. There is a sealing effect of filter cloth between the filter plates.

feature:

The main advantages of this filter press are small wear during feeding, fast filtration speed, high temperature and high pressure resistance, good sealing performance, uniform filter cake washing, low moisture content, uniform filter chamber pressure and not easy to damage the plate, basically suitable for all solid-liquid Separate industries.

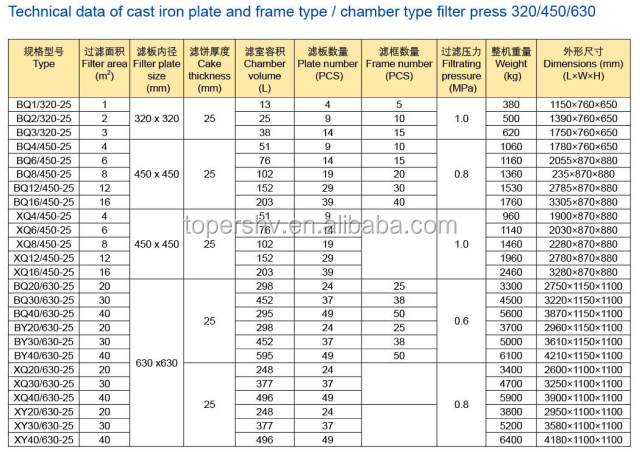

All types of technical parameters:

Cast iron plate and frame filter presses are made of high quality cast iron or ductile iron. Used for high temperature filter material, the filter has high strength, can withstand filtration pressure, and has a long service life. It is widely used in solid-liquid separation in petrochemical, metallurgy, petroleum ceramics and other industries.

More photos:

Filter press pump:

Excellent wear resistance, impact resistance, creep resistance and excellent corrosion resistance. Can adapt to various materials, such as acid, alkali liquid or slurry transportation; various corrosive slurry in smelting industry; dilute acid sulfuric acid industry; environmental protection industrial wastewater, etc.

application:

Automatic unloading filter presses are widely used in coal washing, inorganic, mining, alcohol, petroleum, metallurgy, chemical industry, fuel, medicine, food, textile, printing and dyeing, papermaking, sewage treatment and other fields.

Our factory capabilities:

1. Manufacturing experience, since 1997, we have made many innovations and improvements in the field of filtration and separation equipment. We professionally design filter presses according to customers' requirements, and the lead time for one filter press can be 7 days (if not in stock).

2. Technical ability,

We joined and set the standard of China filter press industry, all our products have CE certificate, and they will be tested before delivery.

3. Our advantages,

We are at the top level in the field of filter press in China, with a land area of over 250,000 square meters and continuing to grow. The filter area of the filter press varies from 1 square meter to 500 square meters, you can always choose the right type.

4. The best after-sale service,

Provide professional operation training, 24-hour troubleshooting, we will try our best to solve your problems on the basis of not affecting the work of your equipment.

company information:

1. We have professionals online to suggest the most suitable machine type for you according to your requirements.

2. Provide you with comprehensive, easy-to-understand and detailed information and technical data about the machine you are interested in; resolve your confusion or questions about the machine

3. If you visit our factory, please make a schedule.

4. If necessary, our technical engineers can also go to your country to guide installation, operation, problem solving, etc.

Automatic filter press, membrane filter press, mechanical filter press, jack filter press, cast iron plate and frame filter press, stainless steel filter press, disc filter press, belt filter press, concentrated dewatering belt press Filter, three-pedal centrifuge, plate centrifuge, decanter centrifuge, tubular centrifuge, vacuum disc filter, various filtering equipment, filter plate, filter cloth, etc.

FAQ:

Q1: How long is the warranty period of the machine?

A1: 12 months.

Q2: How to get more discounts?

A2: Generally speaking, our MOQ is 1 set, the price is reasonable, if the order is larger, we can apply to offer you a proper discount.

Q3: When can I get a quote?

A3: Please let us know the solids content, processing temperature, PH range and daily processing volume, we will reply you as soon as possible.

Q4: How long will it take to receive my product?

A4: Generally within 45 days.

Packaging and Shipping:

All our products:

1. Program-controlled automatic filter press

2. Membrane filter press

3. Hydraulic compression filter press

4. Mechanical compression filter press

5. Jack filter press

6. Cast iron plate and frame/chamber filter press

7. Stainless steel plate and frame filter press

8. Disc filter press

9. Cotton cake filter press

10. Cardboard filter press

11. DY belt filter press

12. DYX high pressure belt filter press

13. DNY Drum Concentration/Dehydration Belt Filter Press

14. Three-belt concentration and dehydration filter press

15. SS type three-foot top discharge centrifuge

16. SD-type three-leg filter bag lifting and unloading centrifuge

17. PD type filter bag lifting and unloading centrifuge

18. Upper and discharge centrifuges, three-legged, clean series SSB, SB

19. SX manual loading and unloading centrifuge

20. PS type manual loading and unloading centrifuge

21. SGZ automatic scraper bottom discharge centrifuge

22. PGZ scraper bottom discharge centrifuge

23. LW series decanter centrifuge

24. Tube Centrifuge

25. Multi-layer stainless steel frame filter

26. Bag filter

27. Diatomaceous earth filter

28. Filter night

29. Filter cloth

30. Vacuum Disc Filter

Premium Cast Iron Filter Press Premium Cast Iron Filter Press Premium Cast Iron Filter Press Premium Cast Iron Filter Press Premium Cast Iron Filter Press Premium Cast Iron Filter Press Premium Cast Iron Filter Press Premium Cast Iron Filter Press Premium Cast Iron Filter Press