China factory hot selling blister card sealing machine

- $3000.00 /set

- 1 set

- Ningbo Nengpai International Trade Co., Ltd.

- Zhejiang, China

- Mr

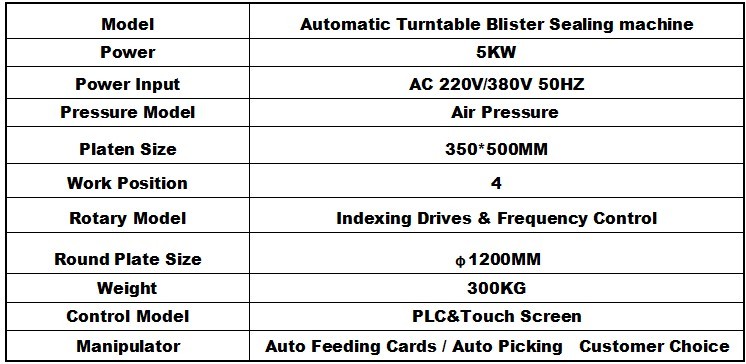

| weight: | 300kg | Dimensions (L*W*H): | 1250*1100*1600mm |

| application: | Food, daily necessities, medical, chemical, machinery and hardware, clothing, textile | brand: | Can Brand Industry |

| Drive Type: | pneumatic | Packaging Details: | wooden box |

| payment terms: | wire transfer | Warranty: | 2 years |

| port: | Ningbo | Voltage: | 220V/380V |

| place of origin; place of origin: | Zhejiang, China | Auto grade: | semi-automatic |

| type: | Blister Packaging Machine | After-sales service provided: | On-site installation and commissioning training, on-site maintenance and repair services, video technical support, online support |

| Health status: | new | Supply capacity: | 200 sets per month |

The process of joining two or more thermoplastic films or sheets by heating the areas in contact with each other to a temperature at which fusion occurs, usually with the aid of pressure. When heat is applied through a mold or rotating wheel that is maintained at a constant temperature, the process is called heat sealing.

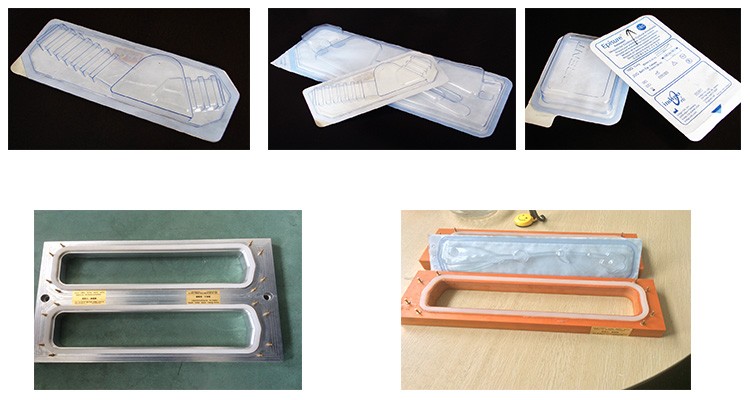

Heat-sealed card-to-card blister packs are a combination of folded or separated front and rear blister cards and clear blister packs that are bonded under heat and pressure. Together, the blister and card form a beautiful, highly visible shelf display of your products.

Heat sealing of plastic to plastic (flip lid, printed blisters, separate front and rear blisters) is done by bonding two parts of plastic together under the influence of heat (radiation or pulse) and pressure. Using the correct type of plastic to make the blister is critical for successful plastic-to-plastic heat sealing. Not all types of plastics are suitable for heat sealing, and depending on the design of the blister, mold design is always a key factor in making the packaging process run smoothly. Another factor to control when producing a high quality finished product is that the blister needs to be cooled under pressure in a separate cooling press to keep the flange perfectly straight.

Heat Seal Card to Plastic - This heat seal blister technique consists of only one board and one blister, so it is very economical to produce. The board is coated with our proven eco-friendly water-based seal coat. After the product is added, the blister can be glued directly to one side of the card using heat and pressure. Blisters are usually made of PET or PVC, depending on the market in which they are used.

Q: Are you a manufacturer or a trading company?

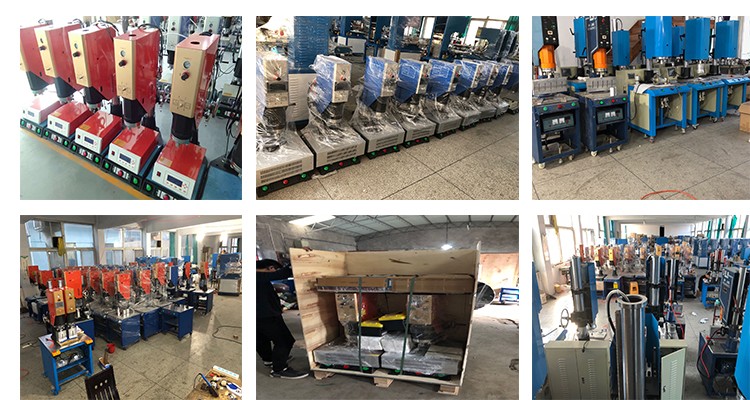

One:We are manufacturer and we have our own two factories.

Q: Can you make matching molds/moulds?

One:Yes, we have mould department, we design and manufacture moulds according to your product samples or drawings.

Q: Will you test the machine before delivery?

A:Yes, we will test each machine and shoot video, then we will feedback the test results to customers. After customer approval, we will arrange shipment.

Q: How to install and operate the machine?

A:We will provide you with installation videos and machine manuals. Follow our steps and you will be easy to install and operate. If you think it can't be done, our engineers can come to your factory for machine installation and worker training.

Q: What about your warranty?

A:We guarantee the whole machine for 1 year.

If the machine parts are damaged during the warranty period, we will send new ones for free (excluding man-made damage).