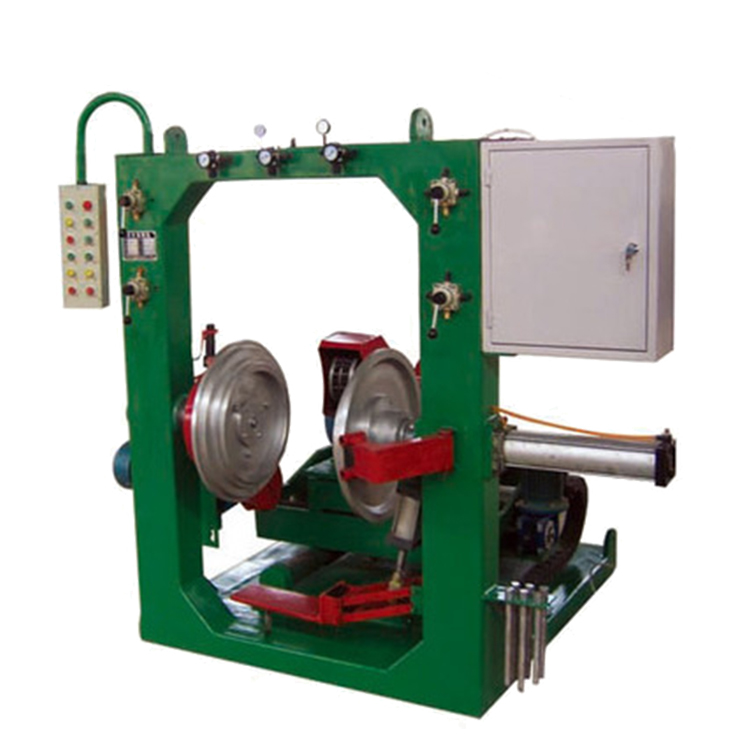

Customized automatic electric heated truck tire retreading vulcanizer

- 1 piece

- Henan Yugong Machinery Co., Ltd.

- Henan, China

- Ms Bonnie Xu

PRODUCT DETAIL

Retreading machine 50-80 sets/day hot and cold truck tire tire retreading production line

Product Description

Introduction of hot tire segmented vulcanization cold truck tire retreading machine in South Africa

The tire recycling line can recycle tires in the diameter range of 400-3000mm according to customer requirements. It has strong applicability, the discharge particle size can be controlled within the range of 5-100 mm, and the output can reach 200-10000 kg/hour. Customized service production can also be carried out according to actual needs. It consists of a variety of combined equipment that can separate rubber, steel wire and fiber materials from trolley tires, engineering tires, truck tires and rubber products. Rubber can be processed into granules or ground. The entire line adopts PLC control system, which is easy to operate and maintain, has the characteristics of low energy consumption and long service life.

Product advantages

Advantages of Customized Fully Automatic Electrically Heated Truck Tire Retreading Curing Press

1 Easy to operate and safe

2 Advantage design

3 Almost fully automatic control

4. Even heating and good heat distribution

5 Durable and reliable

2 Advantage design

3 Almost fully automatic control

4. Even heating and good heat distribution

5 Durable and reliable

Advantages of tire retreading production line

Advantages of Rubber Extruder Gun Tire Retreading Automatic Tractor Tire Retreading Machine

The advantage of renovation is that it is both environmentally friendly and economical! When the tread wears out, the tire only uses about 20%. The carcass accounts for about 80% of the value of a tire and can be re-rubbered to obtain a new "tire life". Approximately 60-80 kg of rubber compound is required to produce a truck or bus tire. Retreading a tire only requires approximately Therefore, in the EU, This saves 15 kilograms of rubber per year, equivalent to the raw material required to produce one car tire. On the other hand, retreading a car tire only requires 28 liters of crude oil.

VIEW MORE

YOU MAY LIKE