FSW Best Quality Backfill Electric Welding Friction Welding Tool Bits

- $46.40 /piece

- 1 piece

- Ningbo Cheeven New Materials Technology Co., Ltd.

- Zhejiang, China

- Mr

PRODUCT DETAIL

| Welding length: | 1000m (regular material) 4000m (special material) | brand: | Qiwen |

| After Warranty Service: | Online support | Health status: | new |

| After-sales service provided: | Online support | Warranty: | 1 year |

| Showroom location: | not any | Marketing Type: | Hot Products of 2019 |

| Custom Support: | OEM, ODM | Shoulder: | 5-80mm |

| Mechanical test report: | if | Main selling point: | long lasting |

| type: | Friction Welder | Applicable industries: | Building materials stores, mechanical repair shops, manufacturing plants, other, aerospace, marine and marine industries, aviation, electronics industry, automotive industry, railways |

| Weight (kg): | 3 kg | Core Components Warranty: | 1 year |

| payment terms: | L/C,Western Union,T/T | Welding depth: | 1-30mm |

| Video external inspection: | if | place of origin; place of origin: | China, Zhejiang, China |

| product name: | Friction Stir Welding Tool Stirrer | Core components: | Other, stirring needle, shoulder |

| Mixing head length: | 100-500mm | Local service location: | China |

Specification

product name | Friction Stir Welding Tool Stirrer |

Product number | FSW |

professional | Depending on the production structure and substrate, we design and manufacture FSW tools. |

Product Description

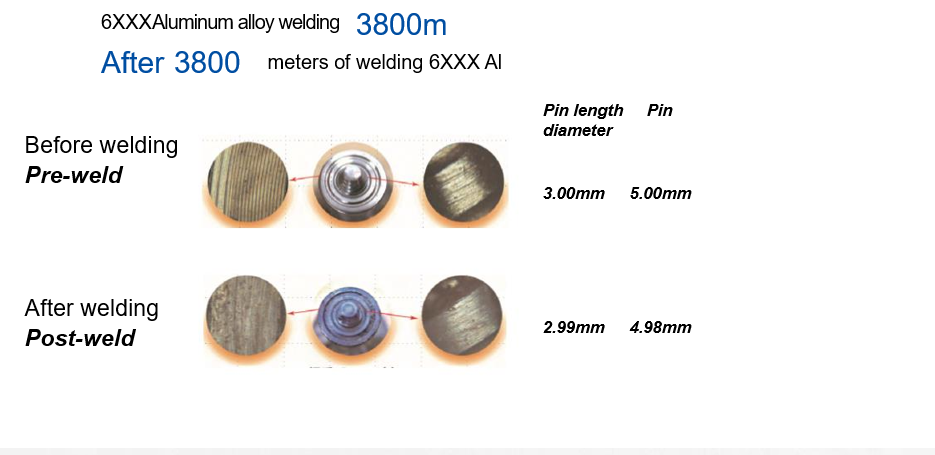

Friction stir welding tool (referred to as stirring head) is one of the key core technologies to realize friction stir welding. Qiwen New Materials utilizes its material expertise to independently develop mixing head materials suitable for different welding materials. After specific heat treatment process, matrix strengthening process and surface treatment process, the service life of the mixing head is fully improved. In addition, Qiwen New Materials has an experienced design and development team of friction stir welding technology and craftsmen. Combined with the actual process parameters and the structure of the welding part, we carefully design special stirring heads for customers. With complete production and processing equipment, heat treatment technology and testing equipment, a variety of specifications and series of mixing heads have been successfully developed. Qiwen New Materials will serve our customers with professional attitude, meticulous service, excellent craftsmanship and fast delivery speed.

FSW Tools type | material type | ||||||||

FSW Tool Type | artificial intelligence | magnesium | copper | iron | titanium | ||||

normal | 0.5-80mm | 0.5-30mm | 0.5-30mm | 0.5-10mm | 0.5-10mm | ||||

lap welding | 1-20mm | 1-10mm | 1-10mm | 1-4mm | 1-4mm | ||||

adjustable | 3-35mm | 3-25mm | 3-25mm | / | / | ||||

Spool Tool | 3-15mm | 3-12mm | 3-12mm | / | / | ||||

fixed shoulder | 1-20mm | 1-20mm | 1-8mm | 1-4mm | 1-4mm | ||||

FFW | 0.3-1.5mm | 0.3-1.5mm | 0.3-1.5mm | 0.5-1.5mm | 0.5-1.5mm | ||||

supplemental exercise | 1-6mm | 1-4mm | 1-2mm | 1-2mm | 1-2mm | ||||

professional | Depending on the production structure and substrate, we design and manufacture FSW tools. | ||||||||

Supply capacity

Equipment introduction

Ningbo Qiwen New Material Technology Co., Ltd. is located in the High-tech Zone, Ningbo City, China. It is mainly engaged in the manufacture of friction stir welding equipment and tools and the processing and manufacture of custom friction stir welding products. The company team has more than 10 years of experience in the research and development of friction stir welding technology, and has formed 4 series of 19 models of friction stir welding equipment and its special stirring head tools. The details are shown in the figure below:

At present, the company's equipment series mainly include desktop, gantry, mobile gantry and backfill. There are 5 types of desktop friction stir welding equipment, 5 types of gantry type, 5 types of mobile gantry type, and 4 types of backfill type. Among them, the company independently developed the patented equipment - the upper and lower double-head friction stir welding equipment, which can simultaneously weld the products on both sides, which greatly improves the production efficiency. In addition, the company can also customize special friction stir welding equipment according to customer needs. In addition to equipment, the company has also independently developed special mixing heads for different types of equipment and different welding materials, including conventional, backfill spot welding, biaxial, telescopic and static shaft types, as shown in the following figure:

Supply Ability & Advantage

Supply capacity: 1500 pieces/piece per month Advantage □Comprehensive improvement of materials □Comprehensive optimization of structure □Higher life □Easier FSW

VIEW MORE

YOU MAY LIKE