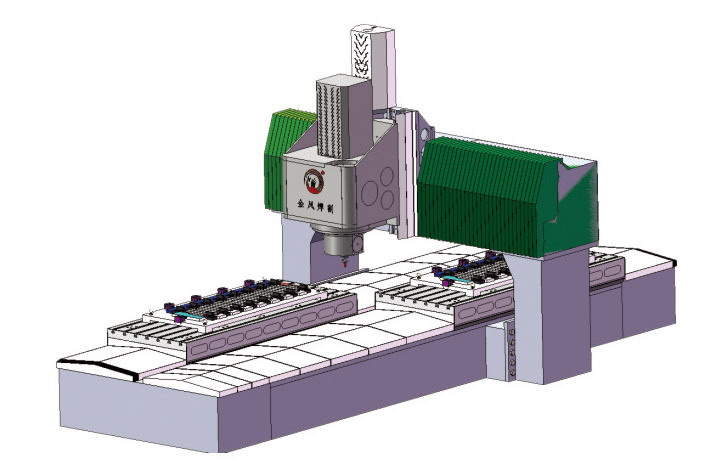

Aluminum Friction Welding Machine, CNC Vertical Static Handle Friction Stir Welding Machine

- $140000.00 /unit

- 1 unit

- Ningbo Jinfeng Welding And Cutting Machinery Manufacture Co., Ltd.

- Zhejiang, China

- Ms Tina Liu

| After-sales service provided: | Engineers can repair machinery overseas | Delivery Details: | 30 |

| Rated Duty Cycle: | 100% | current: | 50A |

| Health status: | new | type: | Friction Welder |

| brand: | Jinfeng | place of origin; place of origin: | China |

| payment terms: | L/C,D/P,T/T | Supply capacity: | 30 units per month |

| weight: | 15000 kg | aspect: | 1500*1000 |

| usage: | Welding aluminum, brass, copper | port: | Ningbo |

| model: | HMC1510 | Packaging Details: | Steel pallets into containers |

| Rated Capacity: | 36KW | Voltage: | 380V |

| Certification: | ISO9001 |

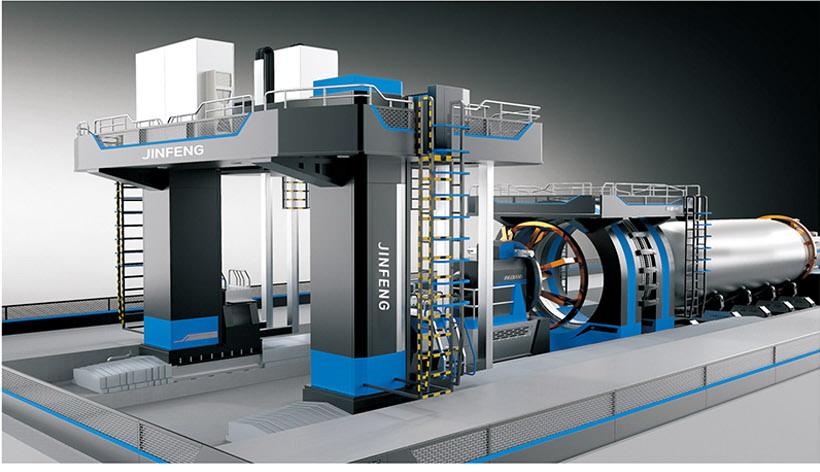

Friction aluminum welding machine, vertical static gantry CNC friction stir welding machine

Model: | HMC1510 |

structure type: | Vertical Static Gantry |

Maximum welding thickness | Aluminum 40mm, copper alloy 20mm, plum alloy 40mm |

X-axis travel: | 0-1500mm |

Y-axis travel: | 0-1000mm |

Z-axis travel: | 0-450mm |

External dimensions of the main part | 4400mm×2400mm×3550mm (length×width×height) |

Outside dimensions of the workbench | 1500mm×1000mm(L×W) |

X-axis working speed | 0-6000 mm/min |

Y-axis working speed | 0-6000 mm/min |

Z axis working speed | 0-3000 mm/min |

Rotation axis (C axis) | n×360°CNC control |

Swing axis (A axis) | 0-5° manual |

CNC controller | Fagor8055, Siemens 828D (depending on customer's choice) |

describe

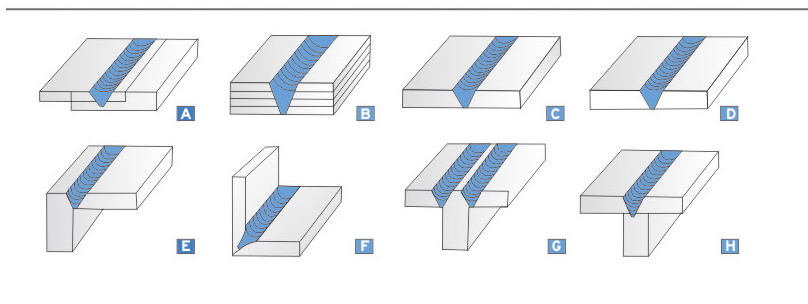

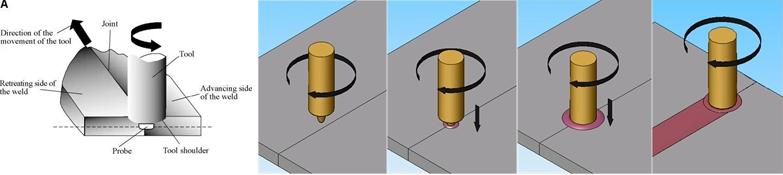

Friction stir welding (FSW) is a solid-state joining process in which a specially designed tool is rotated into the workpiece. Frictional heat is generated by friction between the tool and the welding material, resulting in thermal plasticization of the material. The tool moves along the weld interface, and the plasticized material is swept across the leading edge of the tool and deposited at the solid-state joint of the workpiece after the mechanical forging process of the tool.

feature

1. Double-drive gantry structure, good rigidity and high performance;

2. The C-axis adopts stable worm gear drive;

3.2-D flexible control to ensure constant welding angle;

4. The machine is compatible with no oblique welding function;

5. Simple driving system, high precision and fast speed;

6. Good vibration resistance of mechanical parts;

7. Closed structure, safe and efficient;

8. The control system is humanized and stable;

9. Wireless handle to avoid cable entanglement.

Need a professional recommendation? Please click here to contact us! |