Factory direct sale Scr Denox diesel engine exhaust purification catalyst

- $10.00 / >=5 pieces

- 5 pieces

- Chongqing Licat Environmental Technology Co., Ltd.

- Jiangxi, China

- Mr kevin peng

PRODUCT DETAIL

| payment terms: | L/C, Western Union, T/T, MoneyGram | Classification: | catalyst |

| CAS number: | not applicable | Origin: | Chongqing, China |

| IF: | not applicable | Packaging Details: | Bubble and Carton + Pallet |

| Product Network: | 100cpsi~400cpsi | shape: | round |

| Carrier: | ceramic or metal | Supply capacity: | 2000 liters per month |

| Exchange rate: | 99% | EINECS number: | not applicable |

| model: | Lika | Other names: | Deoxidation catalyst |

| application: | IDiesel vehicle, off-road diesel vehicle | port: | Guangzhou, Shenzhen, Qingdao, Shanghai |

| brand: | Lika | Package preview: |

Product Description

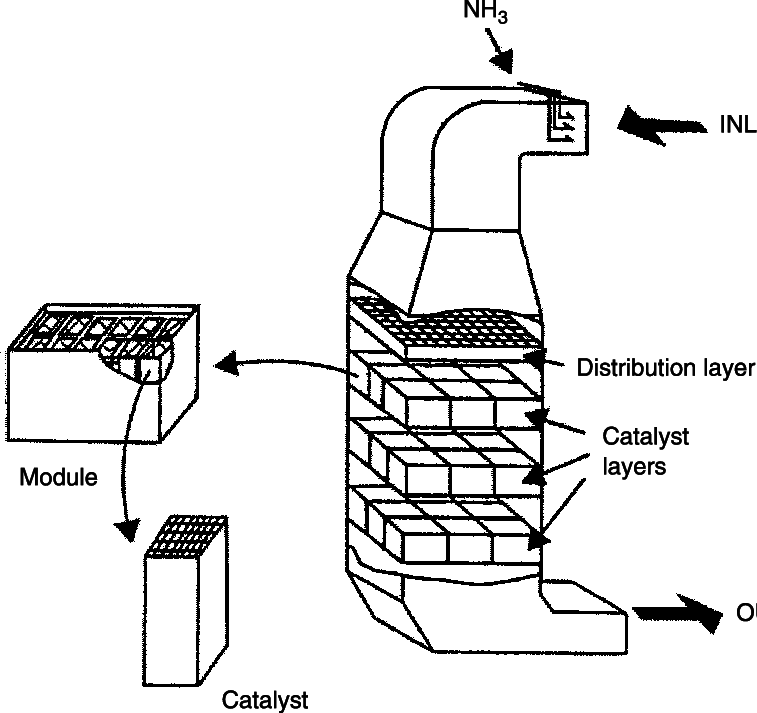

Selective catalytic reduction (SCR) catalyst is a high-tech product, widely used in thermal power plants, coal-fired power plants, waste incineration plants, steel plants, fertilizer plants, nitric acid plants, cement plants, petrochemical plants, etc. need to reduce nitrogen oxides industry that emits. Selective Catalytic Reduction (SCR) catalyst is a denitrification catalyst. At an appropriate temperature, ammonia (NH3) is used as the reducing agent, and the selectivity of the reducing agent is used to preferentially react with nitrogen oxides (NOx) in industrial flue gas. , NOx is converted into non-polluting nitrogen and water, and the NOx reduction efficiency is as high as 90%. Our SCR denitrification catalyst is made of cordierite honeycomb ceramics as the carrier, with TiO2, CuO, V2O5, rare earth and WO3 as the main active components. It has great advantages in terms of strength and prevention of fly ash clogging, abrasion and poisoning.

serial number. | Test items | technical specifications |

1 | Carrier Specifications | 150×150×50, wall thickness = 3.7±0.1 |

2 | NOx concentration | ≤5000ppm |

3 | reducing agent | Liquid ammonia, ammonia water or urea |

4 | airspeed | 3000~10000 hours-1 |

5 | Operating temperature best working temperature | 150°C-420°C 260°C-300°C |

6 | Nitrogen oxide conversion rate | ≥90% |

7 | service life | ≥2 years |

8 | Ammonia slip rate | ≤30ppm |

9 | Bulk density | 0.72±0.05g/ml |

10 | Compressive strength | ≥14 MPa (front) ≥4 MPa (side) |

11 | paint loading | >8.0% |

12 | active metal oxide loading | >9.0% |

13 | Expulsion rate | <1% |

14 | appearance | pure black |

15 | pack | Moisture-proof sealing |

VIEW MORE

YOU MAY LIKE