Fully automatic ACCUTEK AT PRO aluminum and slot paper bending machine

- $5000.00 / 1 - 1 sets

$4500.00 / >=2 sets - 1 set

- Tianjin Wofeng Electromechanical Equipment Co., Ltd.

- Tianjin, China

- Mr Yuanchao Liu

| place of origin; place of origin: | Tianjing, China | Mechanical test report: | if |

| Health status: | new | Applicable industries: | advertising agency |

| Material/Metal Finishing: | aluminum alloy, aluminum | brand: | ACCUTEK |

| Supply capacity: | 3000 sets per year | automation: | automatic |

| Weight (kg): | 350 | Raw materials: | aluminum |

| Core components: | engine, gear | Packaging Preview: | |

| strength: | CNC | Akutec Colors: | Red |

| After Warranty Service: | Video technical support | Main selling point: | multifunctional |

| After-sales service provided: | Engineers can repair machinery overseas | Function: | Slotted on both sides |

| Warranty: | 1 year | year: | 2022 |

| Core Components Warranty: | 1 year | Certification: | ce |

| Video external inspection: | if | Marketing Type: | normal product |

| Type of machine: | Aluminum coil bending machine | Showroom location: | Egypt, Canada, Turkey, USA, France, Philippines, Indonesia, India, Spain, Thailand, South Korea, UAE, Colombia, Japan, Malaysia, Australia |

| port: | Tianjin Xingang | payment terms: | L/C,Western Union,D/P,D/A,T/T |

| Packaging Details: | Export standard wooden box |

Applications

It has complete functions and integrates plate and profile processing. The system integrates the most convenient material and tool switching functions, and the design of double slotting knives and double bending knives can easily handle the processing of materials such as stainless steel, galvanized sheets, aluminum sheets and aluminum profiles. Machines today have the highest ROI on the market.

feeding system | Rolling pressure feed system |

Grooving system | Any angle milling cutter grooving |

Bending system | Flap bending system |

Applicable materials | Aluminium, aluminium profiles and channel profiles |

material height | 10-160mm |

Material thickness | Aluminum plate≤1.2mm Aluminum profile 1.0mm channelume 0.5-1.0mm |

accuracy | ±0.1mm |

input file format | .dxf |

aspect | L1820mm×W600mm×H1300mm |

strength | AC220V 50Hz 1.5Kw |

Gas source | 0.6m3/minute |

gross weight | 350kg |

main feature

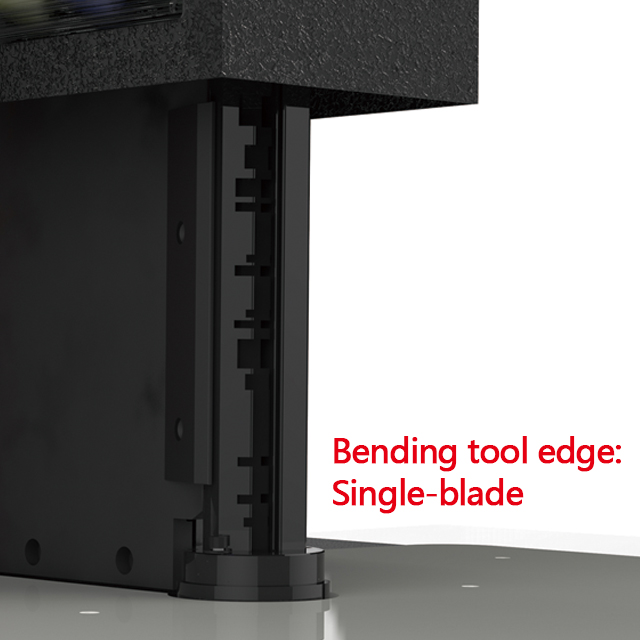

Bending system

Compared with the arc extrusion bending of the traditional aluminum bending machine, the design of the flap-type bending knife is more compact and delicate, which is more conducive to bending with small arcs and small angles.

main feature

feeding system

Rolling feeding method, rolling and embossing treatment. Feeding does not slip. Work with the encoder to ensure that there is no error in the feeding length.

The material conveying bracket can be quickly adjusted according to the material width. Stress-free guide gap adaptation and thin-to-thick switching.

main feature

Grooving system

Automatic calculation of swing angle, double-sided grooving at any angle. Multi-tooth alloy milling cutter, not easy to wear and high strength.

Various settings can be made in the software according to different material and process requirements.

main feature

Board, U-KEY, data extension cable, U disk, warranty card, machete adjustment diagram, mouse pad, 2 power cables, 1VGA cable, hexagonal wrench,

Hardware tools, insurance, mini knives

pre-sale service

* Inquiry and consultation support.

* Sample testing support.

* View our factory.

After-sales service

* Training how to install the machine, training how to use the machine.

* Engineers can repair machinery overseas.