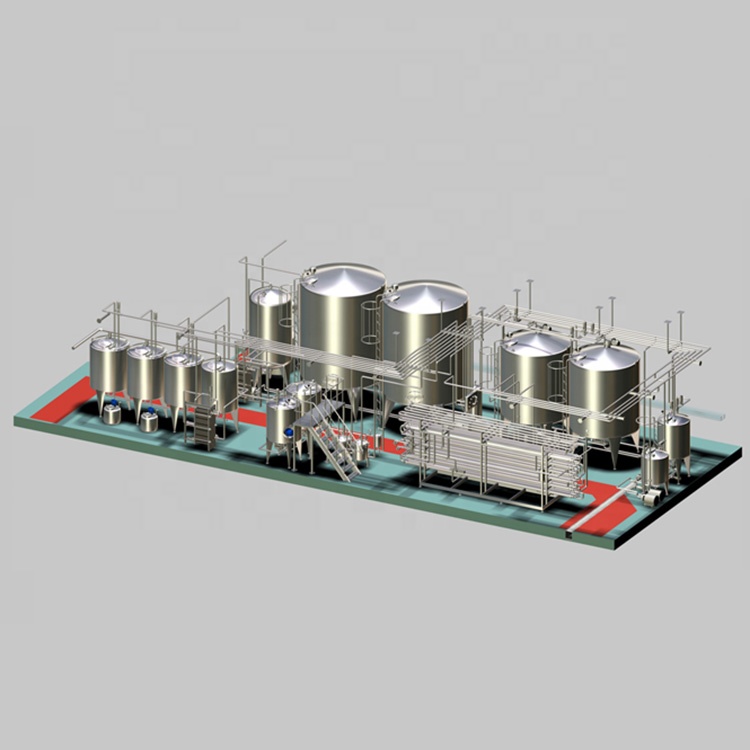

Fully automatic continuous UHT milk production line, UHT milk processing plant

- $500000.00 / 1 - 1 units

$470000.00 / >=2 units - 1 unit

- Shanghai Qingji Beverage Machinery Co., Ltd.

- Shanghai, China

- Ms Jessica Du

PRODUCT DETAIL

| Video shipment inspection: | if | Showroom location: | Vietnam, Peru, Sri Lanka |

| Core component warranty: | 1 year | Certification: | CE certification |

| Origin: | China Shanghai | Finished product: | milk yogurt cream |

| Dimensions (L*W*H): | 6000X2000X2500MM | Warranty: | 3 years |

| After warranty service: | Video technical support, on-site maintenance and repair services | raw material: | fresh milk from cows |

| Health status: | new | brand: | QJ-YGT |

| capacity: | 500-5000 liters/hour | payment terms: | L/C, Western Union, T/T, MoneyGram, PayPal |

| Name: | Turnkey milk production line | weight: | 2000 kg |

| Main selling points: | long lasting | port: | Shanghai/Ningbo |

| Marketing Type: | New Products 2021 | Mechanical test report: | if |

| Voltage: | 380V | Supply capacity: | 10 units per month |

| strength: | 20KW | Core components: | PLC, sterilizer, homogenizer |

| After-sales service provided: | On-site maintenance and repair services | application: | milk processing |

| Advantage: | stable performance | Applicable industries: | Food and Beverage Factory |

| Local service location: | Peru, Kenya, Sri Lanka | Packaging Details: | International standard packing or your request |

Product overview

milk processing plant

Milk processing plants include a range of milk processing equipment used to perform or process various operations on milk such as heat treatment, pasteurization, homogenization, etc.Make a wide variety of dairy products such as cheese, butter, cream, skim milk, yoghurt, flavored or double-mixed milk and more.

Dairy factory includes liquid milk production, cheese production, yogurt production, ice cream production.

Consists of the following parts:

-- Milk tanks: Milk tanks are a major part of any milk processing plant and are used to store raw milk, skimmed milk or cream.

-- Pasteurizer: Pasteurization is the process of heat-treating a product to reduce enzyme activity and kill pathogenic bacteria. This process can be done by using a pasteurizer. The main purpose of pasteurization in dairy plants is to make the product safe for use and to extend the shelf life of the product.

-- Separator: After the pasteurizer, the separator is the third major piece of equipment in a milk factory, which ensures excellent product quality and high performance in milk skimming by preventing the inhalation of damaging air.

-- Homogenizers: Finally, homogenizers help to achieve product variety, improve the texture, mouthfeel and viscosity of cream or juice drinks, and prevent cream lines and sedimentation in dairy products.

-- Pasteurizer: Pasteurization is the process of heat-treating a product to reduce enzyme activity and kill pathogenic bacteria. This process can be done by using a pasteurizer. The main purpose of pasteurization in dairy plants is to make the product safe for use and to extend the shelf life of the product.

-- Separator: After the pasteurizer, the separator is the third major piece of equipment in a milk factory, which ensures excellent product quality and high performance in milk skimming by preventing the inhalation of damaging air.

-- Homogenizers: Finally, homogenizers help to achieve product variety, improve the texture, mouthfeel and viscosity of cream or juice drinks, and prevent cream lines and sedimentation in dairy products.

List of functions

1. Milk collection system

2. Milk mixing system

3. Milk pasteurization

4. Milk filing system

The factory can flexibly produce dairy products such as fresh milk, yogurt, cream, ghee, etc., with a production capacity ranging from 500lph-10,000lph according to site needs.

heat exchange

Milk sterilizer

Homogenizer

product specification

No | Equipment List | data | quantity | Specification |

1 | Plate heat exchanger | SUS304 | 1 | Rapid cooling of milk after collection |

2 | Mixing tank | 2000 liters | 2 | Mix milk with sugar if desired by technique |

3 | pipe filter | SUS304 | 2 | 100 mesh, to remove particles in milk |

4 | Pump | 3 kW | 2 | Centrifugal structure, conveying milk to the next |

5 | Degasser | 2.2kw | 1 | Remove air and odors from milk by vacuum |

6 | Homogenizer | 15 kW | 1 | Prevent milk separation by high pressure process |

7 | UHT Sterilizer | 8.5kw | 1 | Sterilize milk by high temperature and short time |

8 | Aseptic filling machine | 3 kW | 1 | Store pasteurized milk in sachets/cartons |

Sales and Service Network

successful project

african project

Indian project

Russian project

VIEW MORE

Other Products

-

Dairy Factory Complete factory for processing milk and pasteurized milk drinks$23000.00 - $23500.00 / unit

Dairy Factory Complete factory for processing milk and pasteurized milk drinks$23000.00 - $23500.00 / unit