Hot selling steel plate lifting magnet permanent magnet free energy lifter magnetic lifting device magnet lifting crane

- $999.00 /piece

- 1 piece

- Hebei liediao hoisting equipment manufacturing Co., Ltd

- Hebei, China

- Ms Lydia DU

PRODUCT DETAIL

| place of origin; place of origin: | Hebei china | Applicable industries: | other |

| Marketing Type: | New Products 2020 | Showroom location: | not any |

| payment terms: | L/C, Western Union, D/A, T/T, MoneyGram | feature: | Electromagnetic magnet |

| custom made: | Yes | Core component warranty: | 1 year |

| Video shipment inspection: | if | application: | lifting metal |

| Synthetic: | magnet wire | Dimensions (L*W*H): | 700*800*160*90*30 |

| Mechanical test report: | if | Core components: | engine, motor |

| capacity: | 490kg-9000kg (lifting waste) | After warranty service: | Video technical support |

| brand: | hunted down | Safety: | spare battery |

| Health status: | new | product name: | Electromagnetic Chuck |

| port: | Qingdao port and Tianjin port | Weight (kg): | 55 kg |

| Siza: | 700*800*160*90*30/can be customized | pack: | wooden box |

| Supply capacity: | 100 sets per month | Warranty: | 1 year |

Product Description

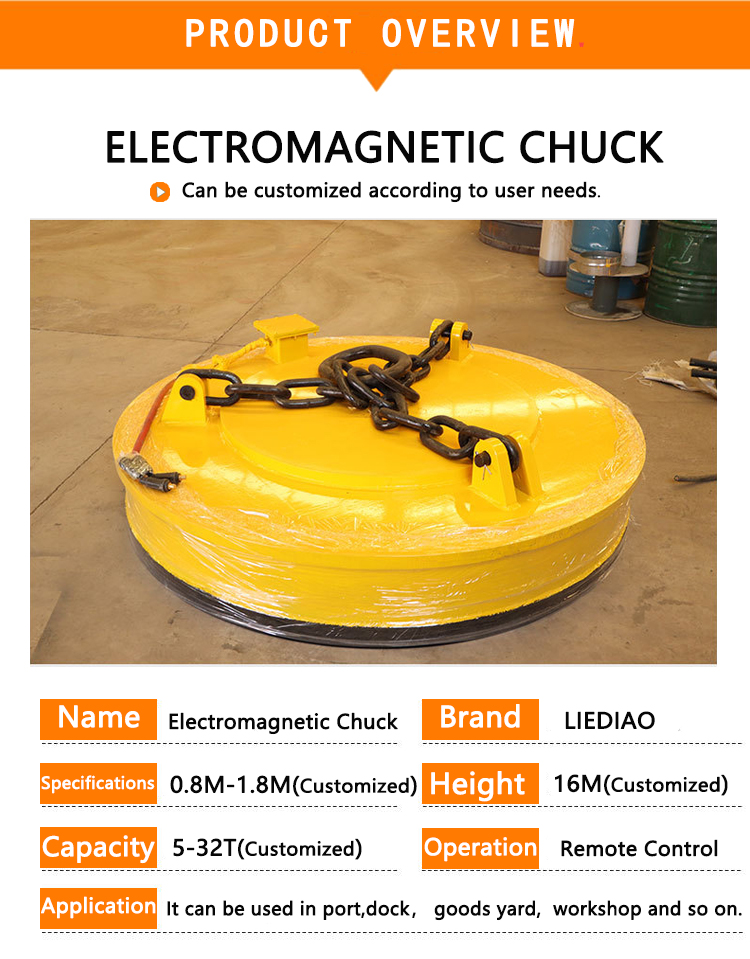

Electromagnetic Chuck

01. Unique ring design, strong suction cup. 02 Excellent material selection, the standard steel adopts hard steel with carbon content less than 0.12%. 03. Precision manufacturing, high rigidity, stable precision, minimal heat change 04. Stable equipment, forced suction, small magnetic force. 05. Ergonomic design, easy to operate. 06. Factory direct sales, give you high-quality products.

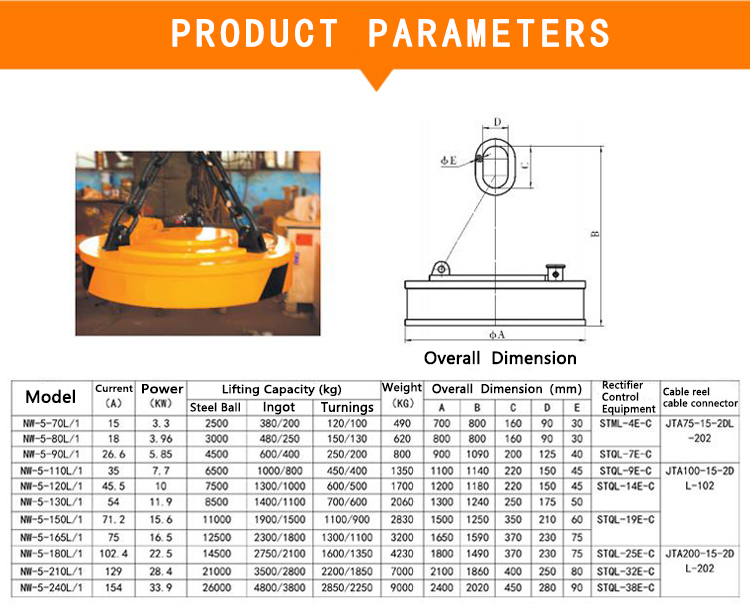

Product parameters

If you need this product, please contact me.

detailed drawing

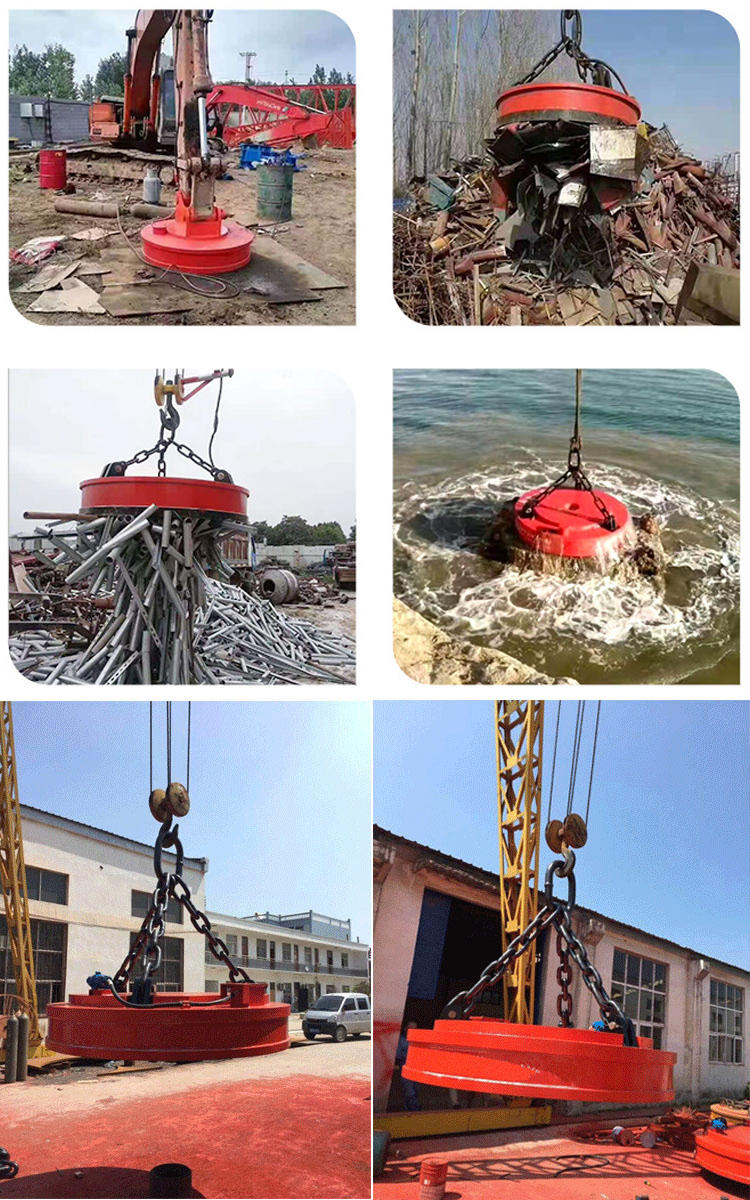

customer photo

attention

1: Remanence occurs. After turning off the power of the electromagnetic chuck, there will be some magnetism left on the sleeve and the electromagnetic chuck, which is called residual magnetism. Therefore, the workpiece is not easily taken out. It cannot be forcibly removed at this time. Just turn the switch to the degaussing position, that is, change the direction of the current in the coil to demagnetize, and the magnetism can be easily removed. 2: Pay attention to maintenance. After a day's work, the operator should wipe the suction cup table clean. Otherwise, the coolant will flow into the slab through the small slit baffle on the workbench, which will dampen the process ring and damage the casting ring. 3: Job placement. When the workpiece is clamped, the positioning surface of the workpiece should be covered with magnetic strips as much as possible to make full use of the magnetic attraction. Small and thin workpieces should be placed in the middle of the magnetic barrier to avoid accidents caused by insufficient suction. 4: Take out the workpiece. When the workpiece with a large bottom area is removed from the electromagnetic chuck, due to the large residual magnetism, there is adhesion between the smooth surfaces, which makes it difficult to remove. At this time, use a wooden rod or a copper rod to loosen it and then remove it. Do not forcibly pull the sleeve out of the electromagnetic chuck, otherwise it will roughen the joint and surface of the suction cup.

other products

VIEW MORE

YOU MAY LIKE

Other Products

-

Best selling portable 220v 200kg 500kg pa800 1000kg remote control mini electric cable crane 150kg with trolley$63.00 - $70.00 / piece

Best selling portable 220v 200kg 500kg pa800 1000kg remote control mini electric cable crane 150kg with trolley$63.00 - $70.00 / piece -

Factory Direct Sale Easy 1/2/3 Ton Operation Black Collapsible Truck Hydraulic Engine Crane For Sale$80.00 / piece

Factory Direct Sale Easy 1/2/3 Ton Operation Black Collapsible Truck Hydraulic Engine Crane For Sale$80.00 / piece -

China factory small electric hoist 500kg cheap 220V cable hoist ladder hoist electric$70.00 / piece

China factory small electric hoist 500kg cheap 220V cable hoist ladder hoist electric$70.00 / piece -

China factory Mini Crane Price Lift Monkey Mini Crane Post Lift$80.00 / set

China factory Mini Crane Price Lift Monkey Mini Crane Post Lift$80.00 / set