Magnetostrictive Probe Automatic Tank Gauge System(ATG) diesel gasoline fuel

- $650.00 / 1 - 9 pieces

$600.00 / >=10 pieces - 1 piece

- Wenzhou Bluesky Energy Technology Co., Ltd.

- Zhejiang, China

- Mr TIM ZHENG

| Material: | Magnetostrictive; | Supply Ability: | 1000 Pieces per Month; |

| Model Number: | SP300; | Port: | ningbo; |

| Brand Name: | LT; | Place of Origin: | Zhejiang, China; |

| Packaging Detail: | wooden case; | Payment Terms: | T/T; |

Gasoline Oil tank level monitor system magnetostrictive level gauge

Description

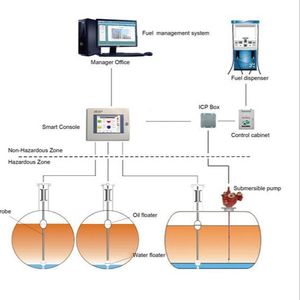

LT622 Automatic Tank Gauge system consists of Magnetostrictive Probe and Smart Console, it is an electronic device, whose basic function is to monitor the fuel level in the tank. It can also tell the operator what is going on inside the tank. In other words, it gives us very important information like fuel level, volume and temperature, water level and volume, high and low fuel level warnings etc. There are different plans to satisfy different customers according to their effective demands.

Application

♦ Liquid level measurement of petroleum, chemical, pharmaceuticals, food, beverage and other industries.

♦ Liquid measurement and level detection of gas station.

♦ Measurement and detection of automatic refueling and selling system.

♦ Sewage treatment

Feature

|

Magnetostrictive Probe |

|

Safety: ExiaIIBT4 (Intrinsically safe) issued by PCEC Accuracy: level accuracy is ±0.3mm Stability: strong anti-jamming ability Efficiency: less than 1 second to test one tank. |

|

Touch Control Console |

|

♦ It can monitor up to 12 tanks and monitor the delivery conditions, it also enjoys a static leak test function. ♦ It can display product level, water level, temperature, volume, ullage. ♦ It enjoys a tank tilt compensation function. ♦ It can display dynamically the change of product level and water level with graphics in proportion, it features a 7 inch colored touch-screen console panel, and each interface displays 4 graphics. ♦ It features an audible and visual alarm function with front panel. ♦ It comes with two RS-232 serial interface communication ports to connect with different brand center console. ♦ It enjoys a record function, all information are stored in memory for future queries ♦ There is an embedded printer in it to print inventory reports, delivery reports, leak reports and shift reports. ♦ It can calculate volume of product by multipoint, which can fully ensure the accuracy of volume of the product. ♦ After connected with Center Console though internet, it can provide information in long-distance for manager to arrange the inventory. ♦ It can monitor the oil pump according to the product level, which can avoid the product spilled and pumpdown.. ♦ It can connect with flow-meter to display delivery information constantly.

|

Specification

|

Magnetostrictive Probe |

|

|

Purpose |

To measure product level, water level and temperature |

|

Titles of medium |

Gasoline, diesel, kerosene, ethanol , water etc. |

|

State of medium |

Liquid |

|

Explosion-proof grade |

ExiaIIBT4 (Intrinsically safe) |

|

Pressure range |

-0.02Mpa~0.6Mpa |

|

Certificate |

PCEC Conformity Certificate of Explosion-proof |

|

Temperature |

-40℃~70℃ |

|

Product Level Accuracy |

±0.3mm |

|

Water Level Accuracy |

±0.3mm |

|

Temperature Accuracy |

±0.2℃ |

|

Height Resolution |

0.023mm |

|

Repeatability |

±0.1mm |

|

Temperature Effect |

Error<0.2mm |

|

Vibration Effect |

Error<0.5mm |

|

Lowest Product Inactive Zone |

2.5'' floater-180mm |

|

Lowest Water Inactive Zone |

2.5'' floater-25mm |

|

Measured Variable |

Product level, interface level and temperature of 5 sensors and average temperature |

|

Measure Range |

600~4000mm |

|

Method of Communication |

RS-485 |

|

Probe Material |

1Cr18Ni9Ti |

|

Power Supply |

+24~26VDC |

|

Protection Class of Probe Canister |

IP67 |

|

Max Communication Distance |

1200m |

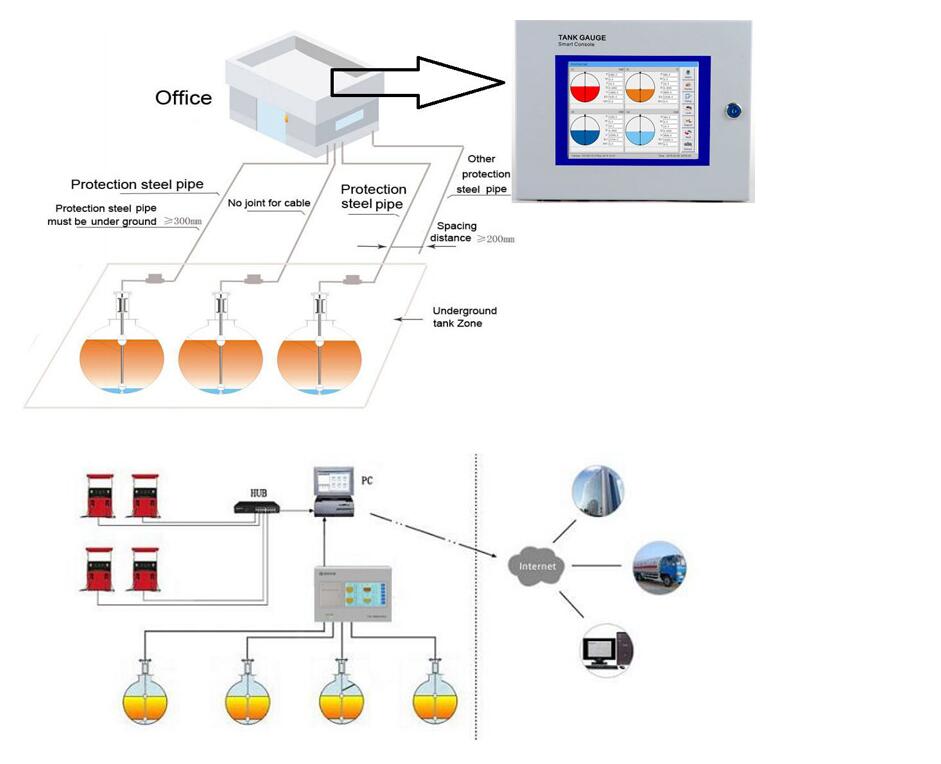

What solution you can get?

1. Probe + Control Console

2. Probe + Control Console+ PCsoftware

3. Probe + Control Console+ PC software+ Internet Remote Query

4. Probe + Control Console + Central Control System(other brands)

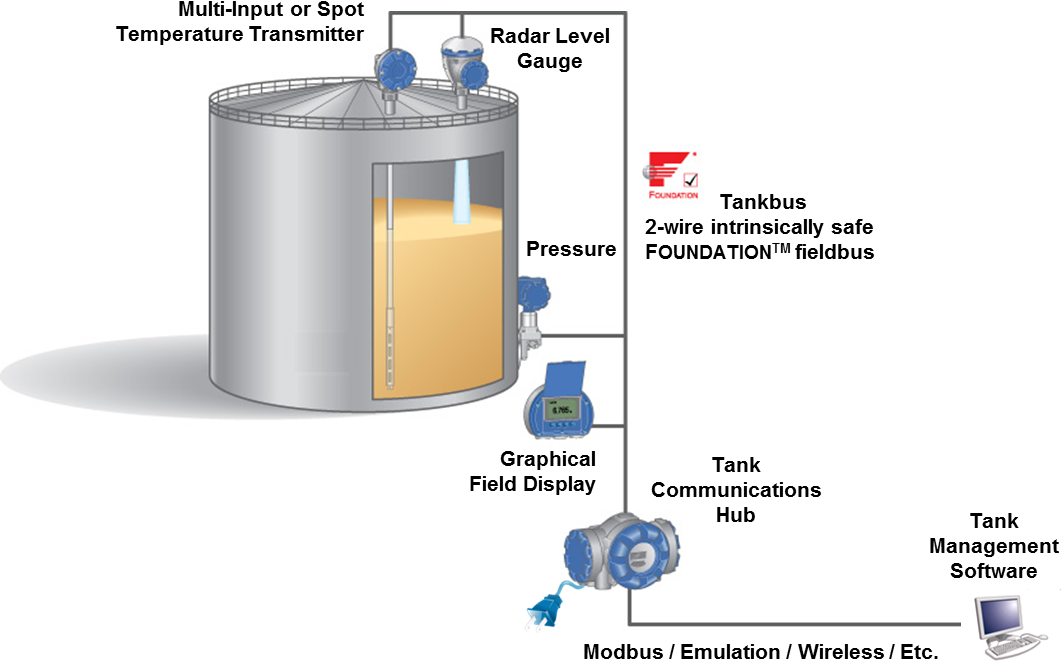

5. Probe (Modbus protocol)+ Other brands Controller