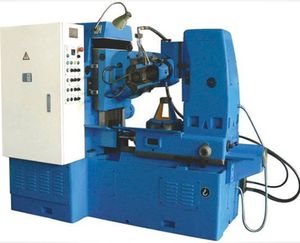

Manual DMTC YB3120H Vinore Gear Cutting Machine Hydraulic Gear Cutting Machine

- $35300.00 /set

- 1 set

- Dalian Dahui Machine Tool Co., Ltd.

- Liaoning, China

- Mr Hui Liu

PRODUCT DETAIL

| Net weight gross weight: | 5000kg | Main motor: | 5.5kW |

| Showroom location: | not any | Marketing Type: | Hot Products of 2019 |

| Mechanical test report: | Not available | Maximum modulus: | 6mm |

| type: | Hobbing machine | Dimensions (L*W*H): | 2300*1800*1700mm |

| Core components: | motor | Core Components Warranty: | 1 year |

| Power (kW): | 9 | Video external inspection: | Not available |

| Maximum workpiece diameter: | 200mm | Voltage: | 380V, 50Hz |

| place of origin; place of origin: | Liaoning, China | Weight (kg): | 5000 |

| Main selling point: | high accuracy | Health status: | new |

| Hob moving distance: | 90mm | Spindle speed: | 500 rpm |

| payment terms: | L/C,Western Union,D/P,D/A,T/T,MoneyGram,L/C On Sight | Applicable industries: | Mechanical Repair Shop, Construction Engineering |

| Dis. From hob center to table center: | 30-175mm | Product Category: | Hobbing machine |

| Warranty: | 1 year | CNC or not: | CNC |

| port: | Port of Shanghai, China | Supply capacity: | 20 manual hobbing machines per month |

| Maximum Hob Diameter/Length: | 160x200 | maximum. Helix angle: | ±45° |

| Packaging Details: | The normal packing is wooden box (size: L*W*H). If exported to European countries, the wooden box will be fumigated. If the container is too tight, we will use pe film packaging or according to customer's special requirements. | brand: | DMTC |

Related Products

Recommended Products

Product Description

Applications

YB3120H semi-automatic gear hobbing machine is an upgraded version of Y3120H common gear hobbing machine. degree

The degree of automation is improved, the square cycle can be realized, and it can partially replace the automatic advance and retraction

Function of 2/3 axis CNC gear hobbing machine. It can realize the operation of one person and multiple machines, which is more simple and convenient

operation, greatly improve work efficiency and output; can process all kinds of straight / helical cylindrical gears, splines, worms

Gears, sprockets, etc., suitable for gear processing in automobiles, motorcycles, reducers, agricultural machinery, and textiles

Machinery, lifting machinery, sprockets, elevators, mining machinery and other industries;

index | unit | YB3120H |

maximum. Workpiece diameter | mm | 200 |

maximum. module | mm | 6 |

maximum. Helix angle | ° | ±45 |

table maximum speed | rpm | 16/32 |

Spindle speed | number of revolutions | 500 |

Z axis rapid feed rate | mm/min | 550 |

The distance from the center of the hob to the center of the table | mm | 30-175 |

The distance from the center of the hob to the work surface | mm | 260—430 |

The distance from the center of the outer bracket to the worktable | mm | 380-800 |

Maximum hob size D×L | mm | 160×200 |

Hob travel distance | mm | 90 |

main motor power | kilowatt | 5.5 |

total motor power | kilowatt | 9 |

Dimensions (L×W×H) | centimeter | 230*180*170 |

net weight gross weight | Kilogram | 5000 |

Manufacturing, Installation, Acceptance Criteria

The manufacture, installation and acceptance of this machine tool conform to the current national standards, industry standards and

corporate standards. The main criteria are as follows:

Gear Hobbing Machine Accuracy Inspection JB/T8360.1-2006

Technical conditions of gear hobbing machine JB/T8360.2-2006

General Rules for Inspection of Machine Tools Part 1: Geometric Accuracy of Machine Tools in Unloaded or Finishing Conditions

GB/T17421.1-1998

General technical requirements for hydraulic systems of metal cutting machine tools GB/T23572-2009

General technical requirements for industrial machinery and electrical equipment GB/T5226.1-1996 Part 1

Gear hobbing machine safety protection technical conditions JB10139-1999

corporate standards. The main criteria are as follows:

Gear Hobbing Machine Accuracy Inspection JB/T8360.1-2006

Technical conditions of gear hobbing machine JB/T8360.2-2006

General Rules for Inspection of Machine Tools Part 1: Geometric Accuracy of Machine Tools in Unloaded or Finishing Conditions

GB/T17421.1-1998

General technical requirements for hydraulic systems of metal cutting machine tools GB/T23572-2009

General technical requirements for industrial machinery and electrical equipment GB/T5226.1-1996 Part 1

Gear hobbing machine safety protection technical conditions JB10139-1999

Features

1. It can process straight teeth/helical teeth and short splines with more than 8 teeth.

Good rigidity and stable working accuracy;

2. When processing gears, it can be cut down or up, and a box cycle can be realized (automatic advance and retreat)

Knife);

3. The machine tool is equipped with a safety device, which can automatically stop;

4. Equipped with automatic lubrication device, machine maintenance is more convenient and labor-saving;

5. Simple adjustment, suitable for mass production of one person and multiple machines;

6. The machine can withstand heavy loads and high-speed hobbing.

7. Adopt hydraulic and electrical linkage control, electrical PLC programmable control, high reliability and low failure rate.

Good rigidity and stable working accuracy;

2. When processing gears, it can be cut down or up, and a box cycle can be realized (automatic advance and retreat)

Knife);

3. The machine tool is equipped with a safety device, which can automatically stop;

4. Equipped with automatic lubrication device, machine maintenance is more convenient and labor-saving;

5. Simple adjustment, suitable for mass production of one person and multiple machines;

6. The machine can withstand heavy loads and high-speed hobbing.

7. Adopt hydraulic and electrical linkage control, electrical PLC programmable control, high reliability and low failure rate.

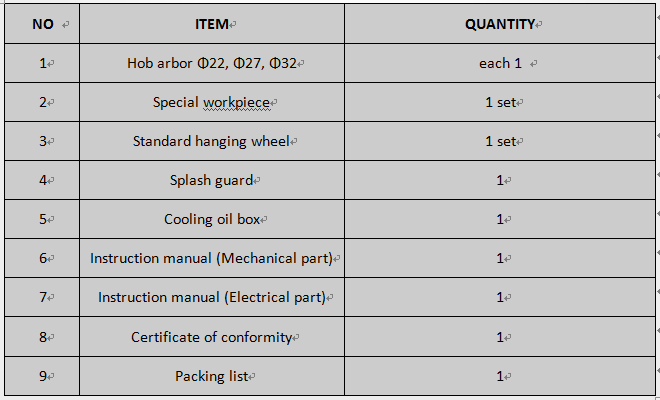

Standard accessories

VIEW MORE

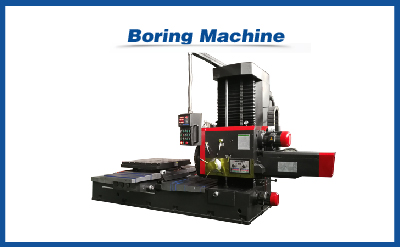

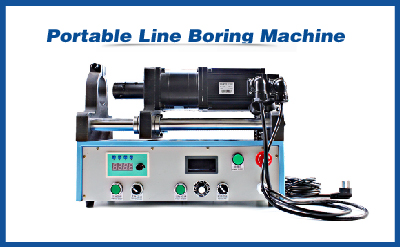

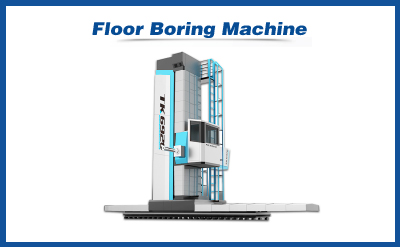

Other Products

-

VDL1000 DMTC brand low price 3 axis cnc milling machine vertical lathe$10500.00 - $12400.00 / set

VDL1000 DMTC brand low price 3 axis cnc milling machine vertical lathe$10500.00 - $12400.00 / set