Oil pan centrifugal separator

- $5000.00 /piece

- 1 piece

- Wuxi Changier Technology Co., Ltd.

- Jiangsu, China

- Ms wuxi chiang

| Supply capacity: | 100 pieces per month | model: | Disc separator |

| Processing: | Splitter | place of origin; place of origin: | Jiangsu, China |

| Voltage: | 200v 380v | Showroom location: | not any |

| Warranty: | 3 years | Video external inspection: | if |

| Purpose: | mineral oil | port: | Shanghai |

| Management Type: | continuous | Marketing Type: | normal product |

| Core components: | PLC, engine | type: | centrifuge |

| Core Components Warranty: | 3 months | Install: | vertical |

| Centrifuge Type: | disc centrifuge | payment terms: | letter of credit, wire transfer |

| Health status: | new | weight: | 500kg |

| Packaging Details: | Wooden pallets and containers | Separate mode: | Precipitation type |

| Applicable industries: | Farms, restaurants, advertising agencies, food and beverage stores, energy and mining, food and beverage factories | Processing Type: | juice |

| custom made: | AVAILABLE | CUSTOM REQUEST | Packaging Preview: | |

| Mechanical test report: | if | brand: | Cangill |

introduce:

The high-speed disc separator is an ultra-high-speed disc separator. The high-speed disc separator has high rotation speed and large separation coefficient. High-scoring equipment that can be used in laboratory pilot tests and can be used in small-scale production. The centrifuge occupies a small area, is easy to operate and has a high degree of automation, and can be used in major universities, enterprises and scientific research institutions.

in principle:

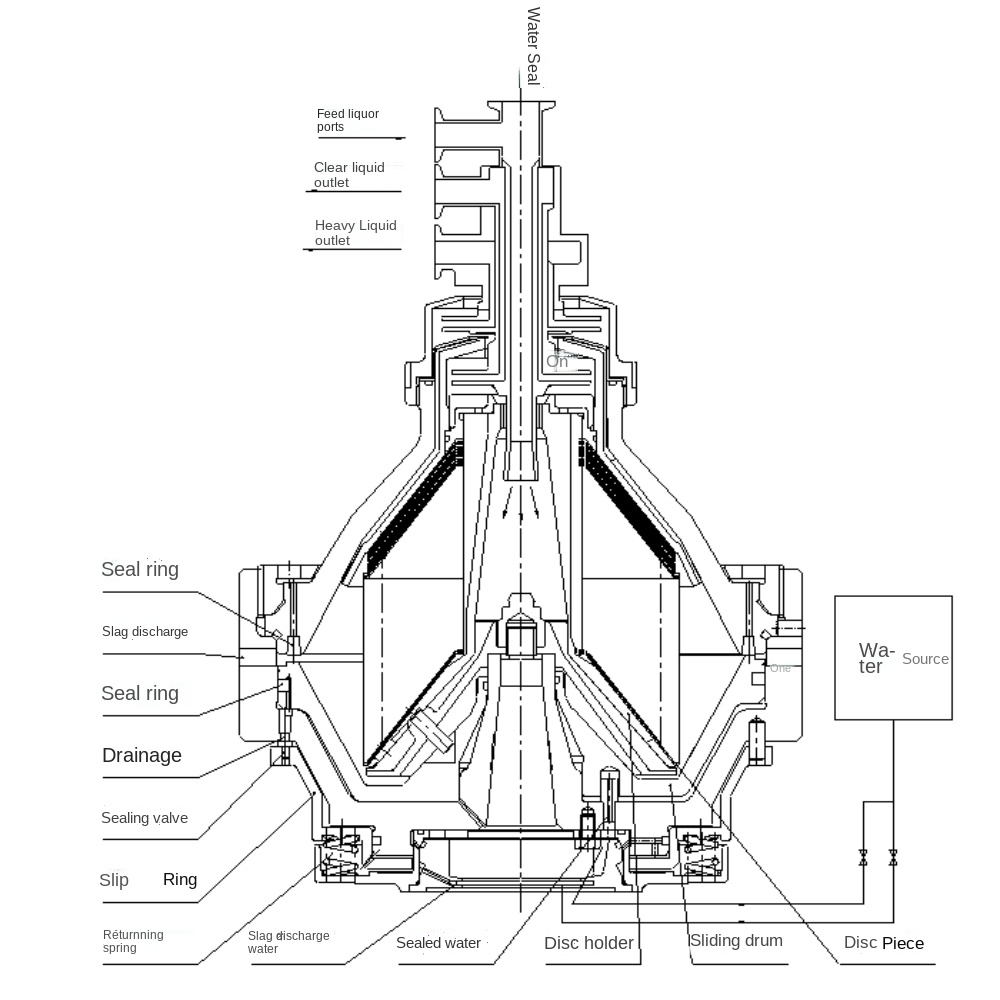

High-speed disc separators are vertical centrifuges. The drum is installed on the upper end of the vertical shaft, and is driven by the motor to rotate at high speed through the transmission device. In the drum, there is a set of disk-like parts - discs - stacked together. There is a small gap between the discs. The suspension is added to the drum from a feed tube located in the center of the drum. As the suspension flows through the gaps between the discs, the solid particles sink to the discs under the action of the centrifuge to form a precipitate. The sediment slides along the surface of the disc, breaks away from the disc, and accumulates in the larger diameter part of the drum. The separated liquid is discharged from the outlet of the drum. The function of the disc is to shorten the settling distance of solid particles and expand the settling area of the drum. Due to the installation of discs in the drum, the production capacity of the separator is greatly increased. After the separator is stopped, the solids accumulated in the drum are removed manually, or discharged from the drum without stopping the slag removal mechanism.

scope:

Industry: fruit juice drinks, tea polyphenol extraction, flavors and fragrances, chlorella concentration, yeast separation, starch, spices, animal and vegetable oils, milk skim, etc.

Pharmaceutical industry: Chinese medicine extraction, biopharmaceuticals, plant extraction, microbial fermentation, antibiotics and vitamin extraction, etc.

Chemical: paint, ink, cosmetics, mineral oil, cutting fluid, biodiesel, chemical energy, etc.

parameter:

1. Drums

Drum speed: 11500rpm; Equivalent settlement area: 10.5x107cm²; Separation coefficient: 14600G; Slag discharge time and emptying time: According to the nature of the material, the slag discharge time is 0.1-0.9 seconds; The slag discharge interval can be adjusted arbitrarily from 1-240min!

2. Motor

Motor speed: 1440r/min; Motor power: 4.0Kw; Start time: 10 minutes; Stop time (without braking device): ≤25min.

3. Work indicators

Inlet pressure: 0-0.1mpa; Outlet pressure: 0-0.1mpa; Working water pressure: 0.2MPa≤P≤0.35Mpa; Noise level: ≤80dB; Vibration level: 1.5mm/s.

Overall weight: 250Kg; Overall dimensions: 9200x790x950mm.