Refractory ceramic fiber heating insulation module 1800c

- $4.00 / >=10 pieces

- 10 pieces

- Goldenwool Thermal Insulation Refractory Co., Ltd.

- Henan, China

- Ms xmx Cai

| Packaging Details: | Packed in cartons or stacked on pallets | Operating temperature: | 1100 |

| Character 1: | low thermal conductivity | Fiber Diameter: | 3-5um |

| payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram, ceramic fiber heating module 1800c | feature: | fire protection |

| color: | pure white | product name: | Aluminum silicate ceramic fiber module insulation |

| chemical composition: | SIO2 AL2O3 | application: | insulation |

| Classification temperature: | 1260 | Role 2: | high temperature |

| Supply capacity: | 1000 tons of 1260 ceramic fiber modules per month | density: | 190-220 kg/m3 |

| port: | Shanghai, Qingdao, etc. |

Refractory ceramic fiber heating insulation module 1800c

| Ceramic Fiber Heating Module Product Line 1800c |

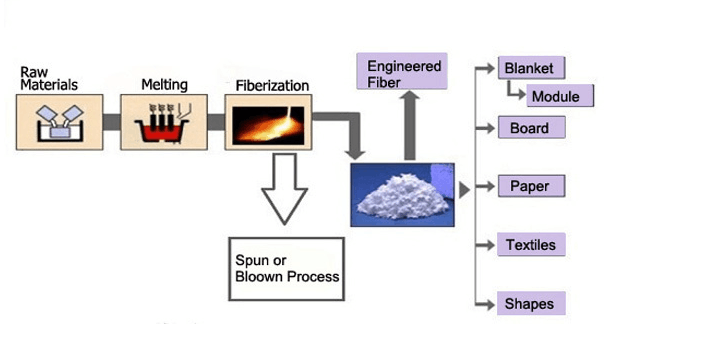

The ceramic fiber module of the kiln lining material is made of ceramic fiber blanket by weighing, then folded or compressed, cut, anchored and inserted, and finally packed.

| Ceramic Fiber Heating Module Product Line 1800c |

The ceramic fiber module is made of fiber blankets folded into an organ shape with a certain width, and then pre-pressed to a certain extent, and bundled in a compressed state.

| Characteristics of ceramic fiber heating module 1800c |

· Low heat storage and low thermal conductivity

· High compressive strength

· Non-fragile material with good toughness

· Accurate size and good flatness

· Uniform structure and easy processing

· Continuous production, uniform fiber, stable performance

· Excellent thermal stability and thermal shock resistance

· Easy to install

| Ceramic Fiber Heating Module 1800c Data |

| HP module | Hertz module | JD-M1600 | |

| Grading temperature (℃) | 1050,1260,1350,1430,1600 | 1050,1260,1350,1430,1600 | 1050,1260,1350,1430,1600 |

|

Working temperature (℃) |

1050-1350 | 1420 | 1600 |

| color | pure white | pure white | pure white |

| Bulk density (kg/m3) | 160-260 | 160-260 | 160-260 |

| Tensile strength (Mpa) | 0.04 | 0.04 | 0.04 |

| Shrinkage(%) | -3 (24 hours) | -1.5-3(1300C,24h) | -0.5(1500C,24h) |

| chemical composition | Al2O3+SiO2 (%)>=97% | Al2O3+SiO2 (%)>=97% | Al2O3+SiO2 (%)>=97% |

| Application of ceramic fiber heating module 1800c |

Ceramics: shuttle kilns, tunnel kilns, kiln cars, batch kilns, kilns for making white cups or ceramic plates, gas ceramic kilns

Steel: heaters, continuous annealing furnaces, galvanizing lines, kiln cars, steel industrial furnaces, roller hearth furnaces.

Heat treatment: annealing furnace, normalizing furnace, kiln car, etc.

Petroleum or petrochemical industry: petrochemical furnace, cracking furnace, cracking furnace, reformer, gas flue, flue lining, etc.

Insulation devices and heating elements for high-end household appliances.

Waste recovery, combustion chambers, vacuum wood kilns, brick kilns, crucibles, vacuum furnaces, wood drying kilns, sponge iron rotary kilns.

| Shipping and Packaging of the Ceramic Fiber Heating Module 1800c |

Plastic bags or cartons according to customer requirements

Within 15 days after receiving the deposit.

| Ceramic fiber heating module 1800c certification |

Quality is our promise to you.It is our responsibility to provide you with high-quality products.