SMT Rework Oven T-962C Infrared IC Heater LED Soldering Machine T962C Desktop Rework Oven

- $400.00 / >=10 sets

- 10 sets

- Shenzhen Youngplus Technology Co., Limited

- Guangdong, China

- Mr Alex Yang

| port: | Shenzhen | way to heat up: | Infrared emission and thermal circulation |

| Package Size: | 780X600X330mm | rated power: | 2500W |

| place of origin; place of origin: | China Mainland) | cycle: | 1~8 minutes |

| usage: | Printed circuit board soldering | Rated Capacity: | 2500W |

| Supply capacity: | 1000 sets per month | payment terms: | T/T, Western Union, PayPal |

| temperature range: | 0-280℃ | Solder PCB area: | 400X600mm |

| Certification: | CE certification | brand: | YPT |

| Types of: | reflow soldering | voltage: | AC220V/110V 50-60Hz |

| control method: | 8 intelligent temperature wave heating | brand: | Pratt & Whitney |

| place of origin; place of origin: | Guangdong, China | weight: | 30KG |

| aspect: | 68*53*25cm | Voltage: | 220V |

| Warranty: | 1 year | Packaging Details: | With standard export packaging |

| Nominal Duty Cycle: | 100% | After-sales service provided: | online support |

SMT reflow oven T-962C infrared IC heater LED soldering machine desktop T962C reflow oven

T-962C reflow oven description:

Infrared IC heater T962C is controlled by microcomputer to work automatically. It can meet different SMD and BAG welding requirements.

The whole welding process is completed automatically, easy to use, and is heated by fast infrared radiation and circulating air, so the temperature is very accurate and uniform.

Fuzzy control technology and visual drawer workbench make the whole welding process complete automatically under your supervision;

The smartest little parts can be soldered.

With high reliability design, you can use it with satisfaction and peace of mind.

T-962C reflow oven features:

(1). Larger maximum area for infrared welding:

The effective welding area reaches: 400x600mm, which greatly increases the scope of use of the machine and saves investment.

(2) A variety of temperature waves for your choice.

Eight kinds of temperature parameter waveforms can be memorized for selection, and the function of forced mobile heating and cooling can be set; the whole welding process is automatically completed and easy to use.

(3) Special heating and temperature equalization with all designs.

The output power reaches 2500W, using fast infrared radiation and circulating air heating, the temperature is very accurate and uniform, the whole welding process is automatically completed, and the temperature parameter wave is selected for you.

(4). Humanized high-tech products.

Stable appearance, visual operation, friendly man-machine interface, perfect temperature wave engineering, from the beginning to the end embodies the technology-based performance;

The flexible size and weight can save you a lot of money. Setting the surface display mode can allow you to have more space; the simple operation instructions allow you to use it at a glance.

(5) Perfect function selection.

Reflow, drying, heat preservation, shaping, rapid cooling, etc. can be used to weld the most intelligent small parts such as CHIP, SOP, PLCC, QFP, BGA, etc.; can be used for product fixation, thermal aging of circuit boards, PCB board maintenance, etc. Various jobs. It is suitable for extensive development and small batch production needs of various enterprises and companies.

T-962C reflow oven technical parameters

machine | Infrared IC Heater | Model | T-962C | |

voltage | AC220V/110V 50-60Hz | |||

way to heat up | Infrared emission and thermal circulation | |||

rated power | 2500W | |||

cycle | 1~8 minutes | |||

control method | 8 intelligent temperature wave heating | |||

temperature range | 0-280Celsius | |||

Solder PCB area | 400X600mm | |||

pack | aspect | 684X504X225mm | ||

Package Size | 780X600X330mm | |||

weight | 27 kg | |||

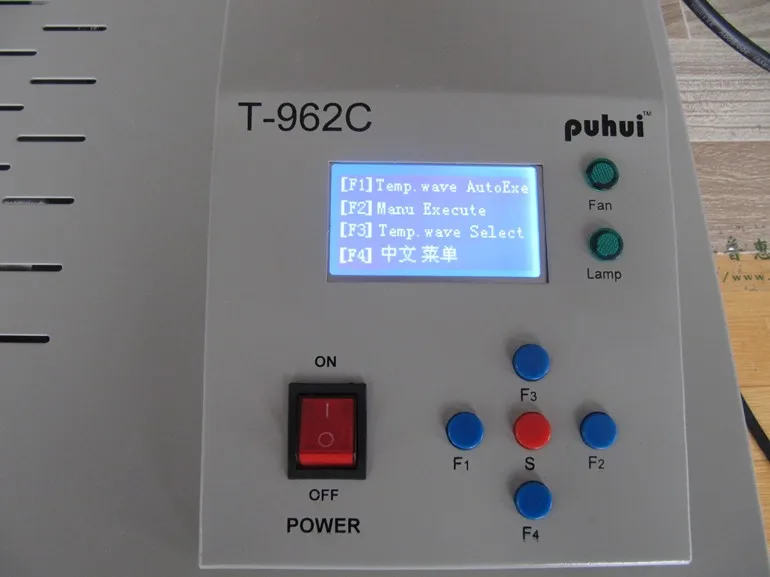

Picture of T-962C reflow oven;

Dear buyer;

If you are interested in our products. Please feel free to contact us. thank you very much.