The present hydraulic hose automatic winding machine

- $4599.99 / 1 - 9 sets

$4299.99 / >=10 sets - 1 set

- Zhejiang Benfa Technology Co., Ltd.

- Zhejiang, China

- Mr Xianjun Liang

PRODUCT DETAIL

| strength: | 0.55kw | payment terms: | L/C, Western Union, T/T, MoneyGram |

| Function: | Winding | feature: | Hank loaded |

| Dimensions (L*W*H): | 1250*1200*1200mm | output: | 80m/min-150m/min |

| port: | Ningbo, Shanghai, Hangzhou | Pick up the spool: | bobbin |

| Automatic level: | automatic | Mechanical test report: | if |

| application: | Winding | Warranty: | 1 year |

| Voltage: | 220V | Memory Capacity: | .twenty four |

| Spindle: | 4 ingots | Supply capacity: | 99 sets per month |

| Origin: | Zhejiang, China | Applicable industries: | Building materials stores, manufacturing plants, machinery repair shops, food and beverage plants, farms, construction, energy and mining |

| Tension type: | Heavy hammer gate tension | Health status: | new |

| Core components: | Bearings, gearboxes, motors, pressure vessels, gears, pumps | Production capacity: | high speed |

| Type of machine: | Tape Rewinder | Winding shape: | Pillar |

| speed: | Maximum 1100m/min | weight: | 5 kg |

| Application fields: | Spandex covered yarn | Marketing Type: | New Products 2020 |

| brand: | this hair | Showroom location: | Egypt, United States |

| Video shipment inspection: | if | Core component warranty: | 3 years |

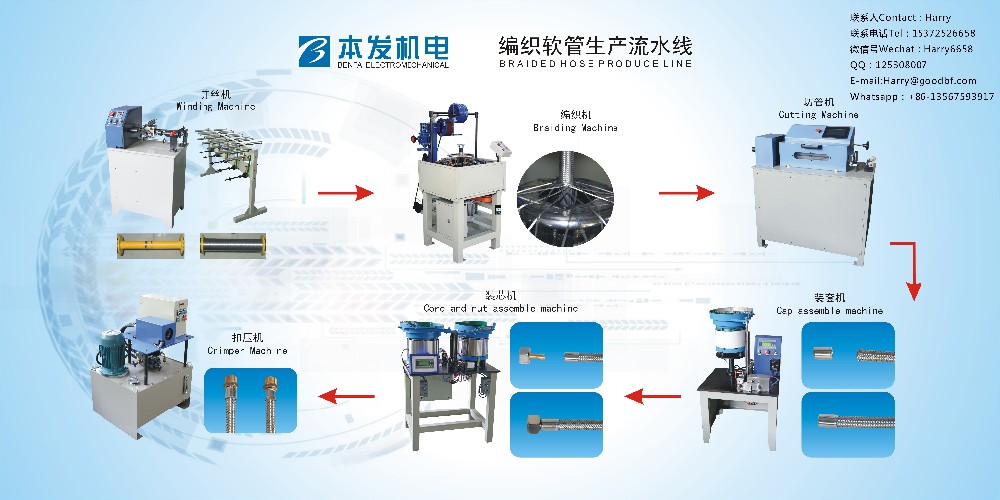

Fully automatic high-efficiency high-pressure hose hydraulic hose winding machine

Product Description

main features

- High degree of automation: broken wire, empty tube, no tube, the automatic machine is self-closing.

- Adopt adjustable speed to adapt to the pitch, no need to change gears

- High production efficiency: The output per hour is three times that of ordinary machines at present, up to 98m/h.

- The noise is low, and the transmission and traction system adopts sound absorption, vibration reduction and insertion devices.

- The maintenance is convenient, the transmission is flexible, and the structure is easy to install and disassemble.

- The main shaft adopts an elastic adjustable device, the position is reliable, and the installation of the bobbin is simple, convenient and flexible.

- Small wear, long service life, key components are made of high-quality materials and heat treatment and lubrication equipment.

Technical Parameters

| BFB16L-114B | BFB24L-114B | BFB36L-114B | BFB48L-114B | |

| Motor Power | 0.75kw | 1.1 kW | 1.5kw | 2.2kw |

| Voltage | 380V/φ-380V/50HZ | 380V/φ-380V/50HZ | 380V/φ-380V/50HZ | 380V/φ-380V/50HZ |

| Carrier PMR | 55rpm(Max) | 45rpm(Max) | 30rpm(Max) | 20rpm(Max) |

| traction speed | 5.26-26rpm | 4.26-18.5rpm | 0.25-1.2rpm | 0.13-0.58rpm |

| Reel | attachment | attachment | Take-up charges | Take-up charges |

| Hose outer diameter | ≤16mm | ≤24mm | ≤36mm | ≤48mm |

| traction wheel | φ200 | φ200 | φ800 | φ800 |

| number of carriers | 16 | 24 | 36 | 48 |

| net weight | 280 kg | 305 kg | 680 kg | 1280 kg |

| Spool size | Outer edge φ56 x inner edge φ22 x 170 (volume: 354cm3) | |||

| Apply | Spindle replacement for weaving wire and yarn | |||

| aspect | 620x500x1580mm | 720x890x1680mm | 1000x1100x1780mm | 1500x1300x2100mm |

VIEW MORE

YOU MAY LIKE