Tongfang DK7720 Z Motor and Taiwan HIWIN Linear Guide Warranty DK77 Series High Speed CNC Wire Cutting Wire Cutting Machine

- $4300.00 / 1 - 4 sets

$3900.00 / >=5 sets - 1 set

- Taizhou Tongfang Cnc Machine Tool Co., Ltd.

- Jiangsu, China

- Mr siyuan chen

PRODUCT DETAIL

| Core Components Warranty: | 1 year | Mechanical test report: | if |

| Main selling point: | high accuracy | Type of machine: | Wire EDM |

| payment terms: | L/C,Western Union,D/P,D/A,T/T,MoneyGram | Maximum cutting speed: | ≥200mm²/min |

| Video external inspection: | if | Marketing Type: | New Products 2022 |

| Warranty: | 1 year | Wire diameter: | 0.12-0.2mm |

| electricity: | "380V±10% / 50/60Hz / 2kVA" | Dimensions: | 1720*1300*1800mm |

| Health status: | new | Multi-knife cutting accuracy: | ≤±0.0025mm |

| Packaging Preview: | Optimum machined surface roughness: | R≤0.8μm | |

| Workbench stroke: | 400*320mm | brand: | Tongfang |

| Showroom location: | not any | Weight (kg): | 800 |

| place of origin; place of origin: | Jiangsu, China | working desk size: | 760*520mm |

| Handling supply current: | 0~20A | year: | 2022 |

| Applicable industries: | Machining, Parts, Machining, Tooling | Supply capacity: | 300 sets per month |

| Core components: | Lead screw, guide rail, stepper motor, electronic control system | Maximum carrying capacity: | 300kg |

Cooperation

Product display

The standard configuration

Details display

product information

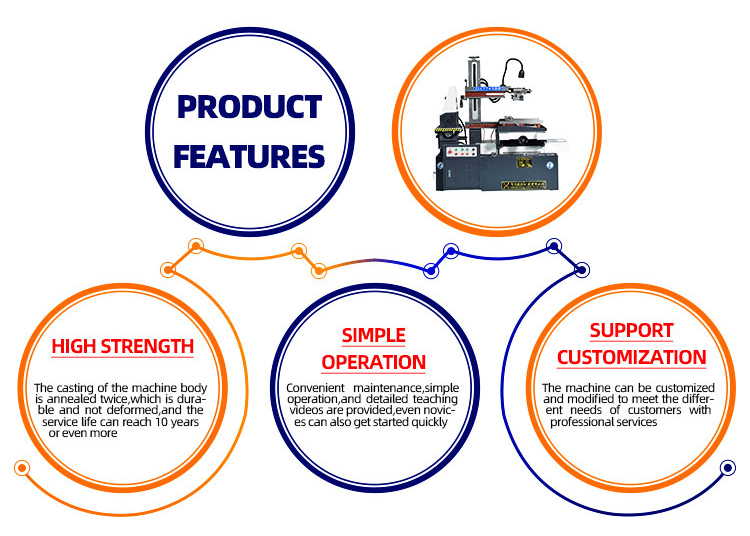

Taizhou Tongfang CNC has been focusing on the research and development of CNC wire cutting products for more than 20 years. The company produces a full range of DK77 CNC wire cutting machine tools, which use high-precision steel-inlaid V-type guide rails (linear guide rails are optional) and P3-level high-precision ball screws. The technology and quality are in the industry-leading position among similar products, with complete models, long service life and high precision. Machine specifications can be customized according to customer needs, non-standard models DK7740(45)J, DK7750(55)J, DK7763J, DK7780J, DK77100J, DK77120J and even larger models. The company also produces ±30°, ±45° swing large taper machine tools and CNC high-precision medium-speed wire cutting machine tools (accuracy ≤ ± 0.0025mm, roughness ≤ 0.8μm). The following are the main parameters of DK77 series machines:

1. Standard maximum cutting taper: ±6°/80mm; (optional ±15°, ±30°, ±45°)

2. Accuracy ≤0.015mm, in line with GB7926-2005 standard; (if equipped with linear guide rail, the accuracy can reach 0.01mm)

3. The best surface roughness is less than or equal to Ra2.5μm (single knife), Ra1.5μm (multiple knife);

4. Molybdenum wire diameter: 0.1-0.2mm;

5. Max. Cutting speed≥120mm²/min;

6. Voltage: three-phase 380V (single-phase 220V, three-phase 220V or other voltages can be customized), power: 3KW;

7. Working fluid: water-based emulsion (recommended DX-1 DX-4 Nanguang-1)

1. Standard maximum cutting taper: ±6°/80mm; (optional ±15°, ±30°, ±45°)

2. Accuracy ≤0.015mm, in line with GB7926-2005 standard; (if equipped with linear guide rail, the accuracy can reach 0.01mm)

3. The best surface roughness is less than or equal to Ra2.5μm (single knife), Ra1.5μm (multiple knife);

4. Molybdenum wire diameter: 0.1-0.2mm;

5. Max. Cutting speed≥120mm²/min;

6. Voltage: three-phase 380V (single-phase 220V, three-phase 220V or other voltages can be customized), power: 3KW;

7. Working fluid: water-based emulsion (recommended DX-1 DX-4 Nanguang-1)

Model | Table stroke (mm) | Table size (mm) | maximum. Cutting thickness(mm) | maximum. load (kg) | Dimensions (mm) | Weight (kg) |

DK7720 | 200*250 | 300*400 | 200 | 80 | 1000*900*1000 | 800 |

DK7725 | 200*320 | 320*510 | 300 | 120 | 1120*950*1240 | 1000 |

DK7735 | 350*450 | 360*630 | 400 | 300 | 1240*1170*1400 | 1200 |

DK7745 | 450*550 | 460*690 | 400 | 450 | 1600*1200*1400 | 1400 |

DK7755(50) | 550*630 | 550*900 | 600 | 700 | 1720*1680*1700 | 2000 |

DK7763 | 630*800 | 650*1040 | 600 | 1000 | 2100*1940*1780 | 2500 |

DK7745J | 450*630 | 460*840 | 400 | 500 | 1700*1600*1600 | 1800 |

DK7755J | 550*800 | 550*1040 | 600 | 750 | 2000*1900*1700 | 2300 |

DK7763J | 630*1000 | 650*1240 | 600 | 1100 | 2300*2200*1800 | 3000 |

DK7780 | 800*1000 | 890*1220 | 600 | 1200 | 3000*2400*1800 | 3500 |

DK7780J | 800*1200 | 890*1560 | 600 | 1500 | 3000*2400*1800 | 4500 |

DK77100 | 1000*1200 | 1060*1590 | 600 | 2000 | 3500*2800*2500 | 5500 |

DK77120J | 1200*1600 | 1230*1880 | 600 | 3200 | 3800*3000*2500 | 8000 |

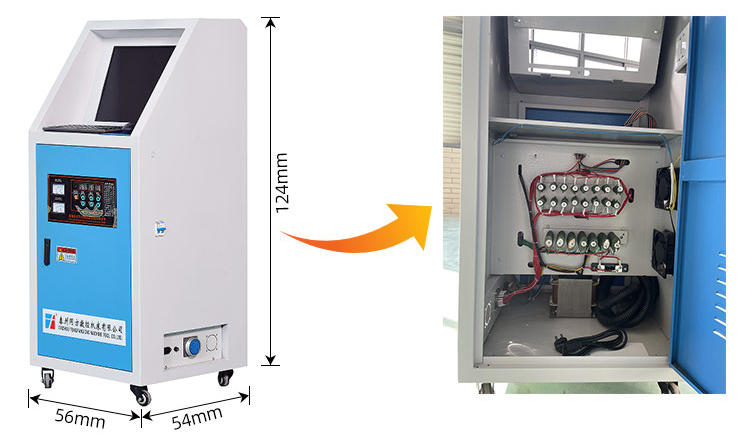

Standard configuration controller

Fully enclosed intelligent controller (one-way, one-cut)

* Standard system: X8 (support multi-language switching)

* Optional system: AutoCut, HL, HF

* Standard system: X8 (support multi-language switching)

* Optional system: AutoCut, HL, HF

* Parameter adjustment reference table, convenient for operators to set processing parameters

* Simple high-frequency parameter adjustment panel (marked with English instructions)

* Reverse processing of short-circuit automatic retraction program with touch dust-proof button

* Mirror cut, also available for any angle and circular rotation

* Can store 4999 wire cutting control instructions at a time

* Automatic shutdown after processing

* With digital display function power-off protection

* Totally enclosed, anti-fouling, dust-proof

* Simple high-frequency parameter adjustment panel (marked with English instructions)

* Reverse processing of short-circuit automatic retraction program with touch dust-proof button

* Mirror cut, also available for any angle and circular rotation

* Can store 4999 wire cutting control instructions at a time

* Automatic shutdown after processing

* With digital display function power-off protection

* Totally enclosed, anti-fouling, dust-proof

optional controller

* Standard system: AutoCut with AutoCAD

* Optional system: X8,HF

Vertical high-speed intelligent controller (one-way, one-cut)

* Standard system: AutoCut with AutoCAD

* Optional system: X8,HF

* Parameter adjustment reference table, convenient for operators to set processing parameters

* Simple high-frequency parameter adjustment panel (marked with English instructions)

* Adopt touch dustproof button

* Integration of programming and control; synchronous programming of processing, real-time tracking and display of processing trajectory; 3D modeling

* CAD/CAM data exchange operations for up and down special-shaped, equal radius, right-angle transition taper processing

* International standard ISO code control

* Totally enclosed, dust-proof, anti-fouling

* Simple high-frequency parameter adjustment panel (marked with English instructions)

* Adopt touch dustproof button

* Integration of programming and control; synchronous programming of processing, real-time tracking and display of processing trajectory; 3D modeling

* CAD/CAM data exchange operations for up and down special-shaped, equal radius, right-angle transition taper processing

* International standard ISO code control

* Totally enclosed, dust-proof, anti-fouling

Fully intelligent multi-pass (multi-cut) controller

* Standard system: AutoCut with AutoCAD

* Support two processing modes: normal fast wire feeding mode and medium wire feeding multi-cut processing mode

* Standard system: AutoCut with AutoCAD

* Support two processing modes: normal fast wire feeding mode and medium wire feeding multi-cut processing mode

* With cutting speed adaptive control

* The cutting process is displayed in real time, and the processing preview is convenient

* Real-time monitoring of the machining status of the X, Y, U, V four axes of the machine tool

* Has a user-maintainable process library that makes multiple runs simple and reliable

* The cutting process is displayed in real time, and the processing preview is convenient

* Real-time monitoring of the machining status of the X, Y, U, V four axes of the machine tool

* Has a user-maintainable process library that makes multiple runs simple and reliable

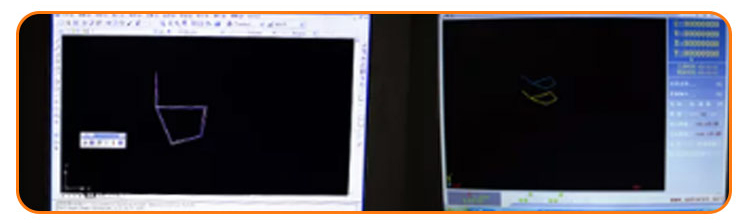

Software system display

AutoCut System with AutoCAD

* The software can be directly embedded into various versions of software such as AutoCAD and CAXA

* Real-time monitoring of X, Y, U, V four-axis machining status of wire cutting machine tools

* One or more cuts can be made to improve processing speed and finish

* With user-maintainable technology library function, making multi-processing simple and reliable

* Support backlash compensation function, which can compensate the screw backlash error of the machine tool and improve the precision of the machine tool

* Support pitch compensation: segmental compensation for the pitch error of the machine tool

* Support two processing modes: normal fast wire feeding mode, medium wire feeding multi-cutting processing mode

* With Chinese, English, Russian language switching

* It is convenient for customers to operate multiple machines by one person, input and output drawings, and equipment can be networked

* The software can be directly embedded into various versions of software such as AutoCAD and CAXA

* Real-time monitoring of X, Y, U, V four-axis machining status of wire cutting machine tools

* One or more cuts can be made to improve processing speed and finish

* With user-maintainable technology library function, making multi-processing simple and reliable

* Support backlash compensation function, which can compensate the screw backlash error of the machine tool and improve the precision of the machine tool

* Support pitch compensation: segmental compensation for the pitch error of the machine tool

* Support two processing modes: normal fast wire feeding mode, medium wire feeding multi-cutting processing mode

* With Chinese, English, Russian language switching

* It is convenient for customers to operate multiple machines by one person, input and output drawings, and equipment can be networked

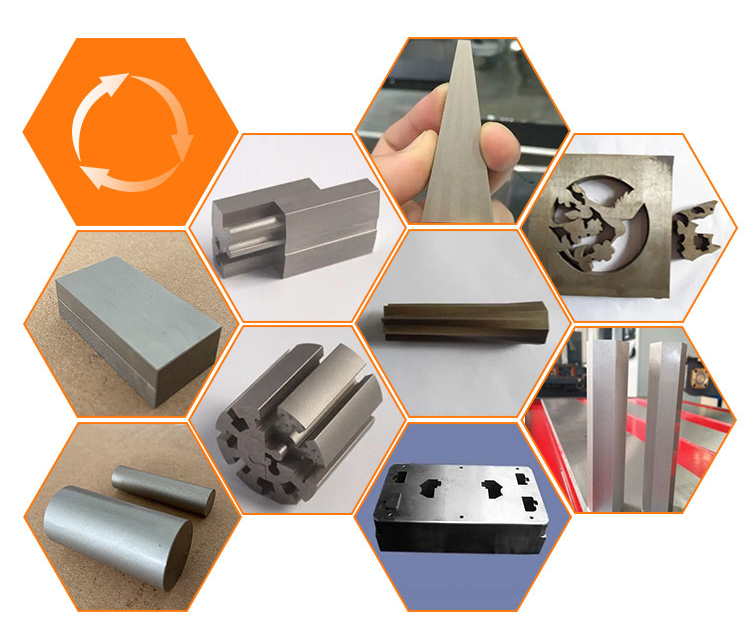

Workpiece display

Certificate

VIEW MORE

YOU MAY LIKE

Other Products

-

Best Selling Repairable DK7735 Wire Cutting Machine Automatic Wire Cutting EDM Machine$5100.00 - $5500.00 / set

Best Selling Repairable DK7735 Wire Cutting Machine Automatic Wire Cutting EDM Machine$5100.00 - $5500.00 / set