Wholesale High Quality Multifaceted Processing Hard Anodized End Facegrinding Machine

- $1.00 /set

- 1 set

- KO-YAN PRECISE MACHINERY CO., LTD.

- Taiwan, China

- Mr

PRODUCT DETAIL

| Package Preview: | ; | Dimension(L*W*H): | 2389,1980,1850; |

| Core Components: | Motor,Bearing,Gear,PLC,Pump; | Supply Ability: | 10 Set/Sets per Year; |

| CNC or Not: | CNC; | Grinding Diameter(Outer)(mm): | 400; |

| Warranty: | 1 Year; | Applicable Industries: | Manufacturing Plant; |

| Voltage: | 220; | Table Travel (X) (mm): | 360; |

| available spindle speed: | 8,000 ~ 50,000 rpm (choose two); | optional components 4: | reverse grinding; |

| Local Service Location: | Taiwan; | Packaging Detail: | wooden case; |

| optional components 6: | Adjustable chuck; | Key Selling Points: | high productivity; |

| Year: | 2021; | Control system: | FANUC Oi-TF; |

| Weight (KG): | 4500; | Video outgoing-inspection: | Provided; |

| Grinding Length(mm): | 250; | Showroom Location: | Taiwan; |

| Place of Origin: | Taiwan; | Cylindricity (mm): | 0.002; |

| optional components 3: | forming punch grinding; | Machinery Test Report: | Provided; |

| optional components 5: | pictogramming software; | Surface Roughness(μm): | 0.8; |

| Max. Length of Workpiece (mm): | 250; | Table Travel (Y) (mm): | 580; |

| optional components 1: | other speed of grinding belt driven spindle; | After-sales Service Provided: | Online support,Field maintenance and repair service,Video technical support,Field installation, commissioning and training; |

| Workhead rotate speed range: | 1-1000 rpm; | Warranty of core components: | 1 Year; |

| Roundness(mm): | 0.0005; | optional components 2: | oil mist air cleaner; |

| Grinding Diameter(Inner)(mm): | 310; | Warranty range: | non-human factor damage; |

| Condition: | New; | After Warranty Service: | Video technical support,Field maintenance and repair service,Online support; |

| Marketing Type: | Ordinary Product; | Max. Weight of Workpiece(kg): | 56; |

| Payment Terms: | L/C,T/T; | Brand Name: | COMORK; |

Grinding Your Device, Shining Our Dream

CNC Hybrid ID&OD Grinding machine

GJ-400B

product specifications

Machine Specification

Cateorgy | GJ-400A |

Max. workpiece diameter | 400mm |

Workhead revolve speed | 0-1000rpm |

Spindle plane manual angle adjust | +15˚ ~ -2˚ |

Max travel: X axis | 360mm |

Max travel: Y/Z axis | 340+240mm |

ID processing scope | Ø 0 ~ 310 mm |

OD processing scope | 380 mm x 100 mm |

Length processing scope(ID) | 250 mm |

Max. workpiece weight | 56kg |

X/Y/Z axis travel speed | 0 ~ 10,000 mm / min |

Axis travel unit | 0.0001 mm |

Spindle motor type | 3HP 2kw 2P |

Spindle rotation speed | 8,000 ~ 50,000 rpm |

Power demand | 15kw |

Machine net weight | 4590kg |

Main Product

GJ-400A

GJ-400B

GO-350

G0-354

GO-356

GJ-412

Belt Driven Spindle

Built-in Motor Spindle

Precision component manufacturing

Our Advantages

Curved surface

Use our Know-how and our independent development pictoprogramming to processing.

Enhance the technology of grinding field.

Enhance the technology of grinding field.

Pictogramming

Original pictograming based on FANUC system ,all controls are clearly and engoromically arranged,an important role is played by the manual control unit ,which facilitate setup close to the grinding process.

And built-in security settings and error warning,prevent new wrokers keyin error,so new wrokers also can finish setup procedure

and manufacture.

And built-in security settings and error warning,prevent new wrokers keyin error,so new wrokers also can finish setup procedure

and manufacture.

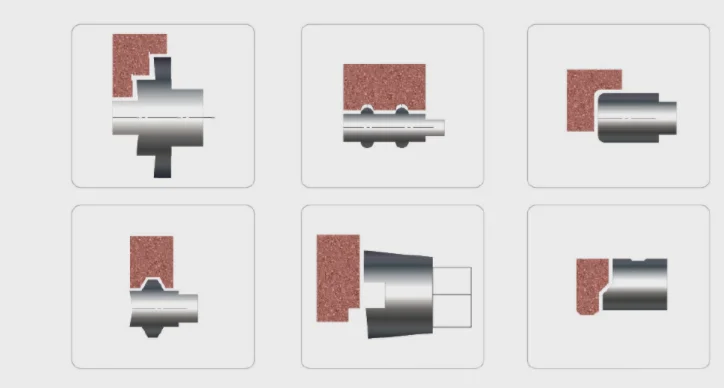

Multifaceted processing

Take controller special software and design,to grinding complex workpiece and multifaceted processing can do once and for all.

Make sure of high efficiency and high degree of precision,both lower the cost of manufacturing.

Make sure of high efficiency and high degree of precision,both lower the cost of manufacturing.

Current monitoring system

Monitoring the current of spindle motor, when wheel touch the workpiece, the current strength of spindle motor will rise.

By this phenomenon to eliminate empty stroke.

By this phenomenon to eliminate empty stroke.

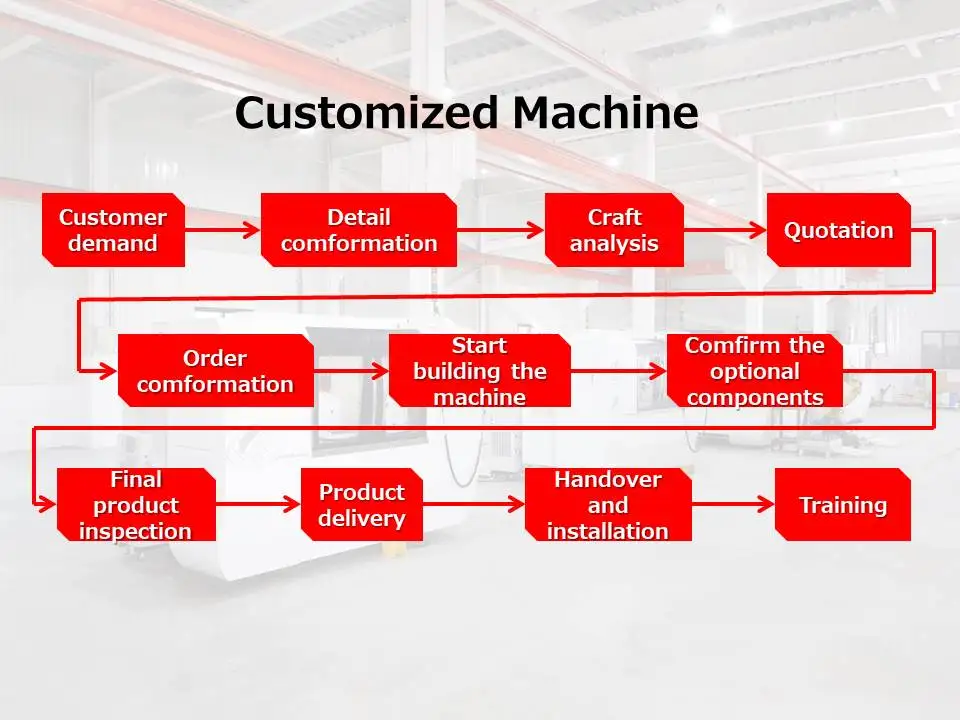

Manufacturing Process

Standardizing Manufacturing Process

All the machine and after services are follow these rule, then whole of the handover machine process it's finish.

Why Choose Us

I'm the Manufacturer, and also the End-User

I am an end-user, so I am familiar with what users really need.

The user-centered perspective is the most fundamental concept for the R&D and manufacture of grinding equipment and for every innovative design. We put ourselves in every user’s shoes, from on-site technicians, customers who purchase gridding equipment to the industry relying on grinding technology and strive for improvement.Company Profile

Brand Story

A Fisherman’s Son Raises the Sails In Pursuit of Grinding Excellence

“Everyone on the ship is a companion and it is with such belief that leads the company to strive for future growth.”

-General Manager Quan-ji Zhou

President Quan-ji Zhou was born into a family from Qingkunshen, Taiwan; that relied on the sea for their livelihood. The ever-shifting nature of the ocean shaped General Manager Zhou into a resilient man with sharp intuitions and a desire to excel. It is through the accumulation of experience that Zhou refined the grinding technology needed to raise his sail of dreams. He has devoted much of what he has learned into machine manufacturing, thereby providing excellent services for upstream clients, as well as meeting the needs of the global grinding industry.

President Quan-ji Zhou was born into a family from Qingkunshen, Taiwan; that relied on the sea for their livelihood. The ever-shifting nature of the ocean shaped General Manager Zhou into a resilient man with sharp intuitions and a desire to excel. It is through the accumulation of experience that Zhou refined the grinding technology needed to raise his sail of dreams. He has devoted much of what he has learned into machine manufacturing, thereby providing excellent services for upstream clients, as well as meeting the needs of the global grinding industry.

Brand Extensions

COMORK and CCM – Born for the Ultimate Grinding

.Brand Value

The intention of innovative breakthrough technologies

COMORK continues to optimize the operation process of grinding equipment, continually breaks through the boundaries of innovation, persistent technological innovation, and pursues the zero-tolerance limit of precision and accuracy.

The intention to manufacture top-notch products

COMORK puts 100% of its time and efforts into the manufacture of grinding equipment, rigorous and perfect manufacturing process, inspection, and testing process before products are delivered to the customers. COMORK keeps a close eye on every step for you.

The intention to serve our customers wholeheartedly

COMORK has professional, practical, and experienced technical and after-sales service teams to provide a full range of technical support, diversified solutions, and rapid service to increase customer loyalty.

The intention to operate our company with honesty

COMORK regards honesty as its core philosophy, treats each other with sincerity both internally and externally, handles things with high standards, and lives with integrity..

Contact Us

FAQ

Q1. Are you a trader or a manufacturer?

A1. We both R&D and manufacturer.

Q2. If we buy the machine from you, what is your guarantee of quality or what do you guarantee?

A2. Always follow ISO quality standards. And because we are also users, the quality will definitely be higher than the ISO

standard.

Q3. When can I get the machine after I make the order?

A3. If it is a standard machine, it will be delivered within 90 days after the deposit is paid. If it is a customized requirement,

the delivery date will be calculated separately according to the details.

Q4. How to install the machine when it arrives? How much does the installation cost?

A4. According to the installation SOP specification, it can be installed by itself without installation cost.

Q5. How long does it take to install?

A5. About 2 days.

Q6. Are the spare parts sold separately?

A6. Yes, please contact us directly, and there will be someone to serve you.

Q7. Does the machine I bought from you have a warranty?

A7. Yes, a one-year warranty is provided. However, damage caused by consumable parts or human factors is not covered by the warranty.

Q8. Can I get the inspection report of the machine I purchased?

A8. When leaving the machine, the machine will be accompanied by a machine inspection report.

A1. We both R&D and manufacturer.

Q2. If we buy the machine from you, what is your guarantee of quality or what do you guarantee?

A2. Always follow ISO quality standards. And because we are also users, the quality will definitely be higher than the ISO

standard.

Q3. When can I get the machine after I make the order?

A3. If it is a standard machine, it will be delivered within 90 days after the deposit is paid. If it is a customized requirement,

the delivery date will be calculated separately according to the details.

Q4. How to install the machine when it arrives? How much does the installation cost?

A4. According to the installation SOP specification, it can be installed by itself without installation cost.

Q5. How long does it take to install?

A5. About 2 days.

Q6. Are the spare parts sold separately?

A6. Yes, please contact us directly, and there will be someone to serve you.

Q7. Does the machine I bought from you have a warranty?

A7. Yes, a one-year warranty is provided. However, damage caused by consumable parts or human factors is not covered by the warranty.

Q8. Can I get the inspection report of the machine I purchased?

A8. When leaving the machine, the machine will be accompanied by a machine inspection report.

VIEW MORE

YOU MAY LIKE