FASTMIX 120FX stationary high quality concrete batching plant for sale

- $1.00 /set

- 1 set

- ATLANTIC MACHINERY MANUFACTURING SARL

- Casablanca-Settat, Morocco

- Mr Atlantic Machinery

| brand: | quick mix | Supply capacity: | 100 sets per month |

| Type of machine: | production line | Power Type: | electrical |

| Core Components Warranty: | Please contact us. | Video external inspection: | Please contact us. |

| Warranty: | 1 year | port: | Casablanca |

| After Warranty Service: | On-site maintenance and repair services | After-sales service provided: | On-site installation, commissioning and training |

| Local service location: | Morocco | Core components: | Please contact us. |

| Showroom location: | Morocco | payment terms: | L/C,D/A,D/P,T/T |

| Health status: | new | place of origin; place of origin: | Morocco |

| Mechanical test report: | Please contact us. | Marketing Type: | Please contact us. |

| Applicable industries: | Manufacturing, Construction, Energy & Mining |

Quick Mix Stationery

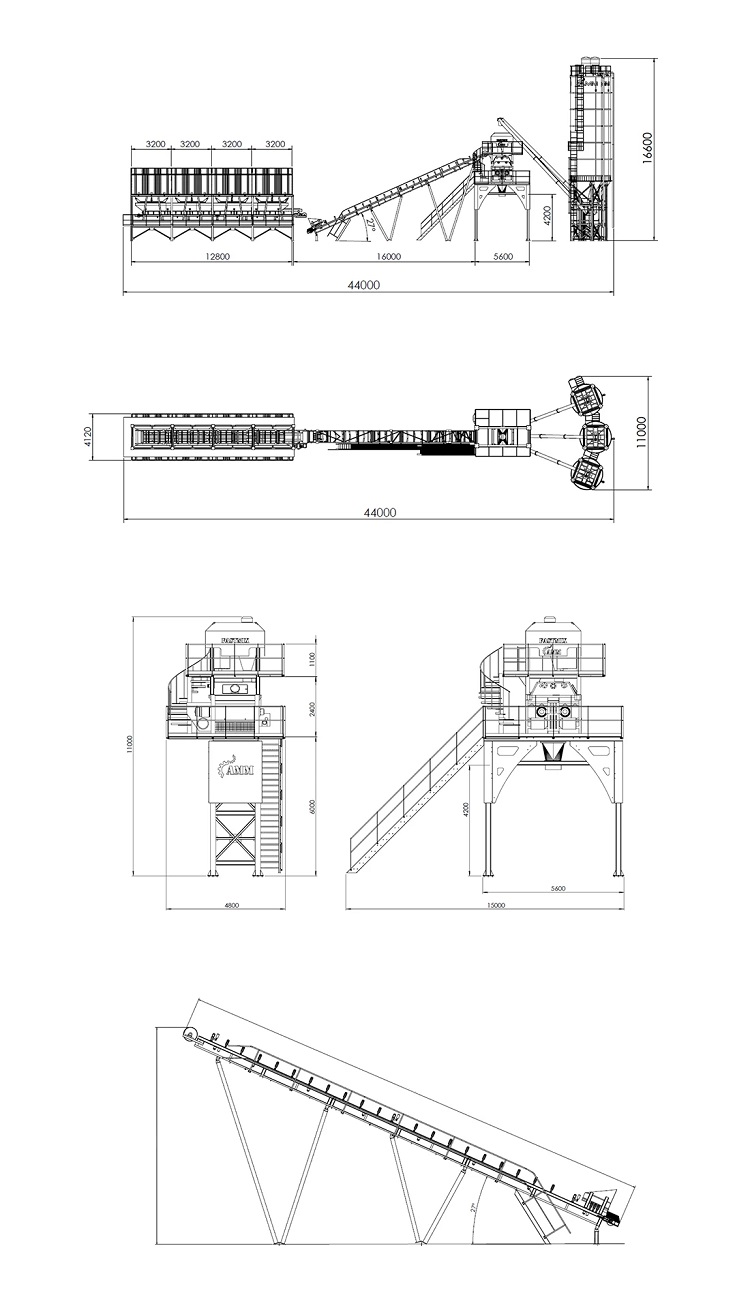

quick mixStationary concrete batching plants are designed for long-term installations. They are best suited for construction projects that require high-volume concrete production. like all othersquick mixRange factory, the strength and reliability of the product are guaranteed. In addition to the special control over the construction process, these concrete plants are easy to maintain to guarantee long-term service. The parts are coated with a specific coating containing an anti-corrosion alloy with an additional double coat.

They are all equipped with twin shaft, turbine or planetary mixers suitable for the required flow, ensuring fast mixing, consistent and high quality concrete production. Each mixer has a structure that contains the cement, water and admixture weighing scales, as well as the water and admixture pumps. The storage and double weighing aggregate system consists of 4 to 6 hoppers with a unit volume of 20m³ to 30m³, each hopper can be customized according to the aggregate type and the storage capacity required by the customer.

Install T-hoppers to maximize efficiency. Use belt conveyors to transfer aggregate to hoppers to optimize mixing cycles and increase productivity.

Cement silos are provided by watertight silos equipped with dust filters, safety valves, level indicators and fluidization nozzles, among others. The capacity and number of silos varies from plant to plant. Cement conveying is provided by screw conveyor.

| Model | Quick Mix 120FX | |

|---|---|---|

| maximum production capacity | m3/hour | 100 |

| Fresh concrete volume | cubic meter | 2 |

| Filling capacity | large | 3000 |

| Vibrated concrete capacity | large | 2000 |

| Aggregate hopper total capacity | cubic meter | 180 |

| volume of each hopper | cubic meter | 4×30 |

| Power board size | mm | 1000 |

| Cement scale capacity | Kilogram | 1000 |

| Capacity switched to secondary | large | 50 |

| Scale capacity | large | 500 |

| Blender Type | – | double knife |

| Air conditioning control cabin | mm | 2400x2400x3000 |

| Air compressor | large | 500 |

| Auxiliary pump | kilowatt | 0.75 |

| mixer motor power | kilowatt | 2×37 |

| Diameter of screw conveyor | o | 273 |

| Electronic equipment | Schneider/ABB/Siemens | |

| automation | AMM |