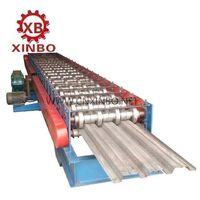

Fully automatic PLC control transformer corrugated fin forming machine

- $37000.00 / 1 - 4 sets

$36000.00 / >=5 sets - 1 set

- Nantong Zhenhuan Trade Co., Ltd.

- Jiangsu, China

- Mr Franks Cao

PRODUCT DETAIL

| Packaging Details: | Transformer corrugated fin formers will be bare in a 20' container | Core components: | PLC, engine, motor, pump |

| Total Power (kW): | twenty two | Uncoiler loading: | 5T |

| Health status: | new | Applicable fin material: | Mild steel, thickness 1-1.5mm |

| Forming speed: | 3-4 fins/min | Dimensions (L*W*H): | 5500 x 1680 x 2200mm |

| Mechanical test report: | if | Corrugated fin height: | 80-400mm |

| Marketing Type: | normal product | Total weight (T): | 9000 |

| Space inside the fin: | 5-8mm | Supply capacity: | 5 sets per month |

| payment terms: | L/C,Western Union,D/P,D/A,T/T,MoneyGram | Control System: | PLC control |

| Material width (mm): | 300-1300 | Fin height (mm): | 80-400 |

| Applicable industries: | manufacturing plant | Material: | steel |

| port: | Shanghai | place of origin; place of origin: | Jiangsu, China |

| Material thickness (mm): | 1.0-1.5 | Video external inspection: | if |

| Forming speed: | 3 fins per minute | brand: | vibrating ring |

| Corrugated fin width: | 300-1300mm | Corrugated Fin Spacing: | 45-80mm |

| Warranty: | 1 year | Showroom location: | not any |

| Core parts warranty: | 1 year | Fin spacing (mm): | 45-80 |

| Main selling point: | Famous brand PLC |

machine description

This machine adopts steel plate welding structure to strengthen, the work is more stable, it is specially used for forming corrugated tanks

Fin wall automatic.

The feeding device adopts servo motor to replace the original stepping motor, and the feeding is more accurate.

The original design adds a station roller leveling device, and the quality of the finished fins is better.

Ribs can be added as needed.

Fin wall automatic.

The feeding device adopts servo motor to replace the original stepping motor, and the feeding is more accurate.

The original design adds a station roller leveling device, and the quality of the finished fins is better.

Ribs can be added as needed.

main feature

1) Uncoiler: hydraulic expansion, active drive, capacity 5T.

2) Hydraulic station: max. The maximum pressure is 21MPa, the flux is 94L/min, and the pump motor is 22kW; the main hydraulic components are from Taiwan.

3) Main molding unit: servo feeding, automatic molding.

4) Shearing device: hydraulically driven shearing and forming fins, automatic.

6) PLC control system: PLC and touch screen are all Siemens brand, China joint venture.

2) Hydraulic station: max. The maximum pressure is 21MPa, the flux is 94L/min, and the pump motor is 22kW; the main hydraulic components are from Taiwan.

3) Main molding unit: servo feeding, automatic molding.

4) Shearing device: hydraulically driven shearing and forming fins, automatic.

6) PLC control system: PLC and touch screen are all Siemens brand, China joint venture.

Product Specifications

Do not. | thing | data |

1 | Raw coil width | 300-1500mm |

2 | steel thickness | 1.0-1.5mm |

3 | Fin height | 50-400mm |

4 | Fin spacing | 40-80mm |

5 | space inside the fin | 5-8mm |

6 | Forming speed | 3-4 fins per minute |

7 | machine weight | 12000 kg |

8 | Machine size | 5800x1680x2200mm |

sample photo

VIEW MORE

Other Products

-

Steel rim production line$450000.00 / set

Steel rim production line$450000.00 / set -

Steel wheel weld slag trimmer$68000.00 / set

Steel wheel weld slag trimmer$68000.00 / set -

Tubeless wheel roll forming machine China$85000.00 / set

Tubeless wheel roll forming machine China$85000.00 / set -

High voltage distribution and power transformer making equipment for oil-immersed and dry type transformers$100000.00 / set

High voltage distribution and power transformer making equipment for oil-immersed and dry type transformers$100000.00 / set