High Alumina Refractory Brick Insulation Refractory Firebrick Refractory JM23 26 Lightweight Mullite Brick Refractory

- $0.40 /piece

- 1 piece

- Henan Hongtai Kiln Refractory Co., Ltd.

- Henan, China

- Ms Hongtai Refractory

| Packaging Preview: | port: | Tianjin, Qingdao, Shanghai | |

| product name: | Insulation refractory brick | Magnesium oxide content (%): | 0.05% max |

| type: | factory | Bulk Density: | 0.6~1.3g/cm3 |

| Packaging Details: | Mullite Lightweight Insulation Brick Plywood Tray | Silicon carbide content (%): | 0.1~1.4% |

| Original Equipment Manufacturer: | Yes | Al2O3 content (%): | 38%-75% |

| Material: | Mullite | Fe2O3≤: | 1.0% |

| CaO content (%): | 0.34% | Certificate: | International Organization for Standardization |

| size: | 230mm*114mm*75mm | shape: | brick |

| Supply capacity: | Monthly output of 1000 tons of thermal insulation refractory bricks | sample: | free |

| place of origin; place of origin: | Henan, China | brand: | Hongtai |

| application: | industrial furnace | CrO content (%): | 0.1~0.3%MAX |

| color: | white | SiO2 content (%): | 15%~45% |

| Refractoriness (degree): | Ordinary (1580° | model: | Insulation refractory brick |

| payment terms: | L/C,Western Union,D/A,T/T,MoneyGram |

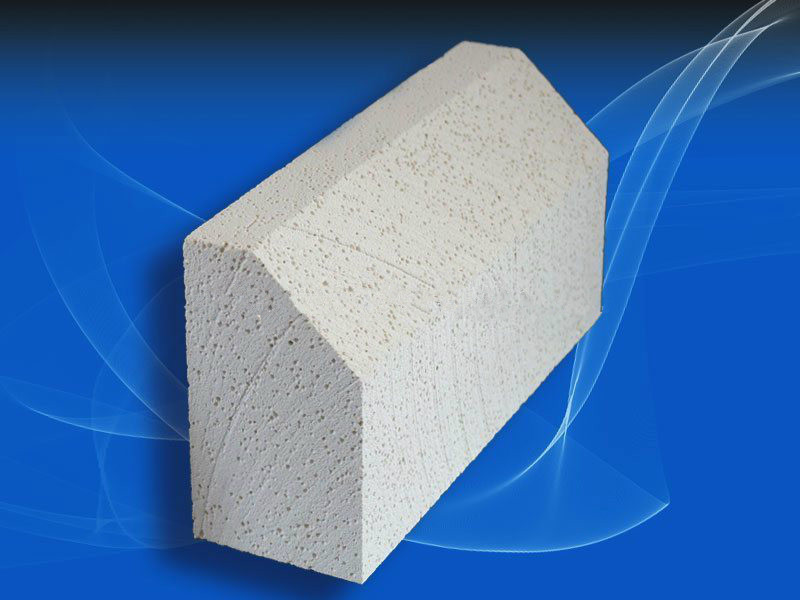

Insulating refractory bricks (1260C-1600C)

Insulation refractory brick is a kind of high-quality refractory and heat-insulating material with high temperature resistance. Insulation refractory bricks are mainly used for hot blast stove top, blast furnace chimney and bottom, glass melting furnace regenerator, ceramic high temperature furnace lining, etc.

The insulating refractory brick is made of mullite as the main crystal phase, and the alumina content is about 65~75%. Mullite insulation bricks have high refractoriness up to 1790℃. Its apparent initial softening temperature is about 1600-1700 °C. Its cold pressing strength is about 70~260MPa.

Mullite heat insulating refractory bricks can be divided into 1350 heat insulating refractory bricks, 1450 heat insulating refractory bricks and 1550 heat insulating refractory bricks according to different operating temperatures, and can be divided into light mullite bricks and heavy mullite bricks according to different bulk weights brick.

Insulating refractory bricks (1260C-1600C)

Insulation refractory brick is a high-quality high-temperature material with the following excellent properties:

Low thermal conductivity and low heat capacity

High purity and low impurity content

Excellent high temperature strength

good thermal shock resistance

Low expansion conductivity

Strong resistance to acid and alkali erosion

Features of Lightweight Mullite Insulation Bricks:

1. Excellent compressive strength

2. Excellent thermal stability

3. Low thermal conductivity

4. Low heat storage

5. High aluminum, low iron, low alkali flux content

6. Accurate size

7. Design the packaging

Insulating refractory bricks (1260C-1600C)

Specifications of insulating refractory bricks

|

Insulation refractory brick |

||||||

| item/index | HT23 | HT26 | HT28 | HT30 | HT32 | |

| Al2O3 % | 37 | 54 | 64 | 72 | 77 | |

| Fe2O3 % | 1.0 | 0.9 | 0.8 | 0.7 | 0.5 | |

|

Thermal conductivity (w/m*k) |

400℃ | 0.14 | 0.27 | 0.32 | 0.41 | 0.49 |

| 600℃ | 0.16 | 0.29 | 0.34 | 0.43 | 0.5 | |

| 800℃ | 0.18 | 0.31 | 0.36 | 0.44 | 0.51 | |

| 1000℃ | 0.20 | 0.33 | 0.38 | 0.45 | 0.53 | |

| Classification temperature (℃) | 1260 | 1430 | 1540 | 1650 | 1760 | |

| Thermal expansion 1000℃ (%) | 0.5 | 0.7 | 0.8 | 0.9 | 1.1 | |

| Bulk density (g/cm3) | 0.55-0.62 | 0.78-0.8 | 0.88 | 1.03 | 1.25 | |

| Cold pressed strength (Mpa) | 1.2 | 1.6 | 2.1 | 2.5 | 3.5 | |

| Rupture modulus (Mpa) | 0.9 | 1.4 | 1.6 | 2.1 | 2.1 | |

| Reheat linear change (%)

CT-30℃*8H |

1230℃

-0.5 |

1400℃

-0.5 |

1510℃

-0.5 |

1620℃

-0.9 |

1730℃

-0.9 |

|

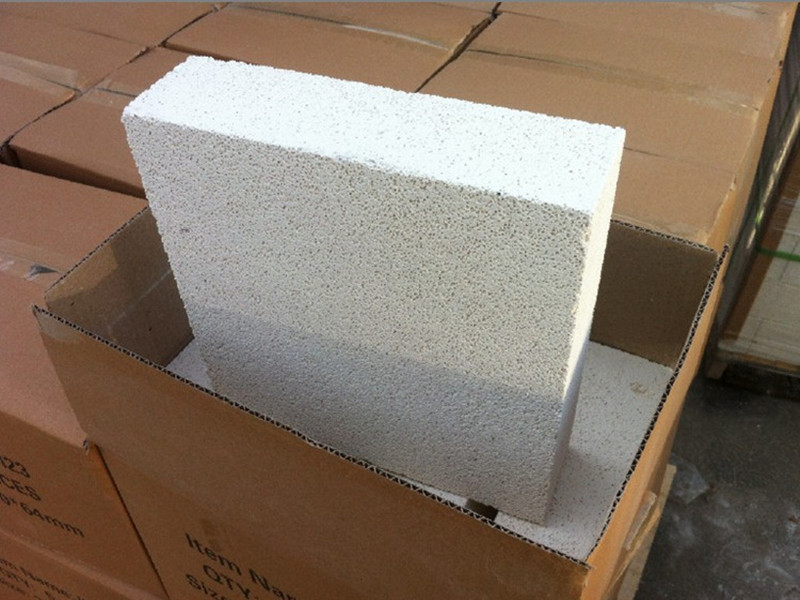

Common sizes of insulating refractory bricks

| size | ||

| Length × Width × Height (mm) | L×W×H/H (mm) | L×W×H/H (mm) |

| 230×114×65 | 230×614×64 | 250×640×64 |

| 230×114×76 | 230×614×76 | |

| Other sizes according to customer requirements | ||

Insulating refractory bricks (1260C-1600C)

Package: Standard export wooden pallet with cardboard and PET tape, 10 bricks in 1 box, 48 boxes in 1 pallet.

1. The sturdy packaging will protect the goods from any possible damage during transportation.

2. The sturdy packaging and the overall filling can prevent the box from shaking and vibrating.

3. We must take the necessary precautions, the packaging can protect the goods from theft or rain.

4. We can confirm that we have taken all possible precautions to ensure that our products reach our customers around the world in the best possible condition.

shipping: From any port in China by boat or train, samples can be shipped by international express.

Insulating refractory bricks (1260C-1600C)

Power Industry

Petrochemical industry

Metallurgical industry

Furnace insulation

Other insulation

Recommended for use as the primary hot face refractory behind other refractories in furnaces, kilns, flues, refining vessels and heaters, regenerators, gas generators and mains, soaking pits, stress relief furnaces, reactor chambers and similar blast furnaces Lining or backup insulation temperature industrial equipment.

Insulating refractory bricks (1260C-1600C)

1. Respond in time,

Respond to your inquiries in a timely manner, select multiple recommendations according to your needs, quickly reply to emails and provide solutions.

2. Free samples

Quality assessment accepts samples and trial orders.

3. Strict quality control

Arrange production on time and strictly control quality.

4. Shorter delivery time.

Book the earliest boat or plane to guarantee delivery time.

5. Professional Services

Provide all detailed news and pictures from order to delivery;

Provide relevant export documents and originals when necessary;

Warm and thoughtful after-sales service