High sales laboratory chemical reactor 100L laminated glass reactor

- $1500.00 /piece

- 1 piece

- Zhengzhou Obor Instrument Co., Ltd.

- Henan, China

- Ms Judy Zhu

PRODUCT DETAIL

| State of health: | new | place of origin; place of origin: | Henan, China |

| strength: | 120W(1:3) | Warranty: | 1 year |

| weight: | 135 | product name: | Laminated glass reactor |

| structure: | 304 stainless steel frame | Packaging Details: | 1) Glass and other fragile parts are wrapped with cushioning bubbles; 2) Stainless steel and other accessories are wrapped with stretch film, and then put into wooden boxes; 3) Pearl cotton is filled around the wooden box, and parts and accessories are separated by pearl cotton again, which is enough to protect Product Safety. |

| port: | Shanghai/Zhengzhou/Shenzhen/Guangzhou/Yiwu etc. | Certification: | CE certification |

| Types of: | Custom Laminated Glass Reactor | Jacket volume: | 30 liters |

| Mechanical test report: | Not available | Core components: | Motor Controller |

| Condenser: | Vertical Serpentine Condenser | Core component warranty: | 1 year |

| Glass material: | GG-17 (3.3) borosilicate glass | Automatic level: | semi-automatic |

| spinning speed: | 0-600 rpm | Seal type: | PTFE double seal |

| way to heat up: | Thermal oil heating | Dimensions (L*W*H): | 780*730*2450mm |

| Showroom location: | not any | brand: | Belt and Road |

| Video shipment inspection: | Not available | Main selling points: | high productivity |

| Supply capacity: | 300 sets of laminated glass reactors per month | payment terms: | Western Union, Wire Transfer, MoneyGram, Credit/Debit Card; PayPal; Apple Pay; Google Pay, etc. |

| Marketing Type: | New Products 2020 | Package preview: | |

| Work pressure: | -0.1~0.1Mpa | Voltage: | 220V/50Hz, 110V/60Hz |

| capacity: | 100L | Applicable industries: | Manufacturing plants, food and beverage plants, farms, printing plants, construction, energy and mining, pharmaceutical plants |

Principle and Application

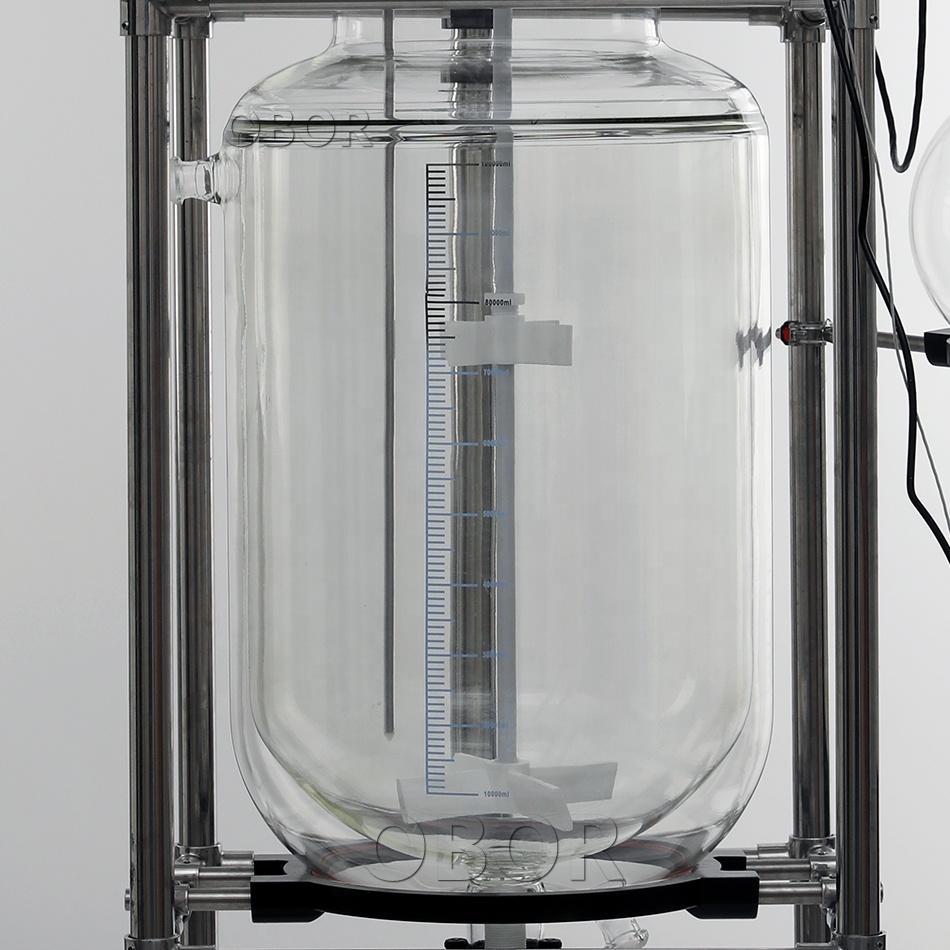

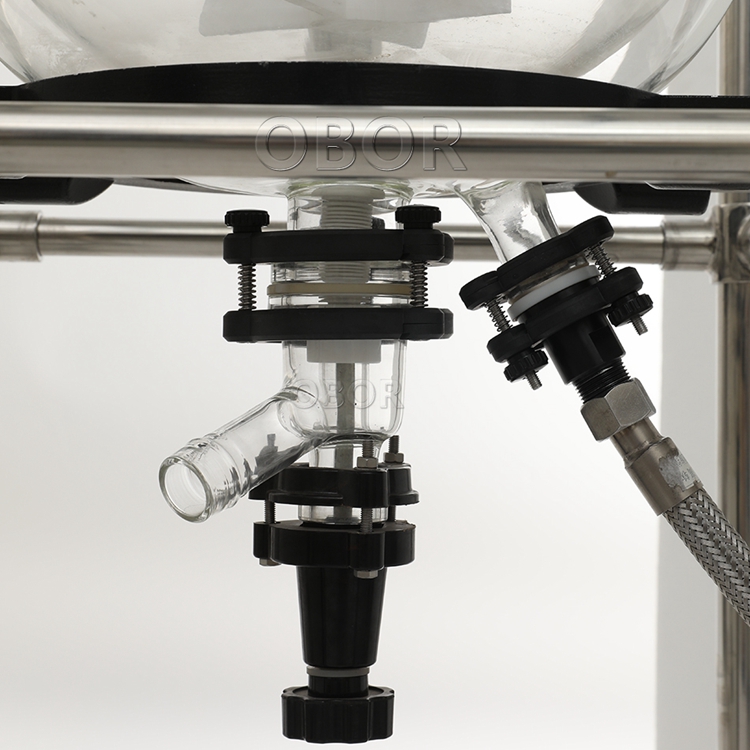

The glass reactor is designed with double glass. The inner layer is filled with solvent for the stirred reaction. The interlayer can be connected to cold and heat sources (refrigerated liquid, hot water, hot oil) for cyclic heating and cooling reactions. The reaction can be stirred under normal or negative pressure. The stirring speed can be adjusted by the knob, and the temperature and speed are displayed on the LCD. The catalyst can be added evenly by adjusting the constant pressure funnel or the regulating valve on the dropping tank. Using the heat exchange function of the condenser, the reaction product can be recovered by distillation. The equipped reflux head can also be used for reflux experiments. All reacted products can be discharged through the bottom discharge valve. Widely used in medicine and chemical industry, especially in pharmaceutical synthesis, fine chemical industry, petrochemical industry, new material synthesis and other fields.

technical parameter

Model | JGR-100L | |||

Response capability | 10L~100L | |||

Jacket amount | 30L | |||

*Voltage | 220V/50Hz [110V/60Hz optional] | |||

*Motor Power | 200W (1:3) | |||

Rotating speed | 0-600 rpm | |||

controller | Temperature, speed LCD digital display, speed knob adjustment, equipped with PT100 probe | |||

control precision | ±1℃ | |||

temperature range | -120℃~300℃ | |||

work pressure | -0.1Mpa~0.1Mpa | |||

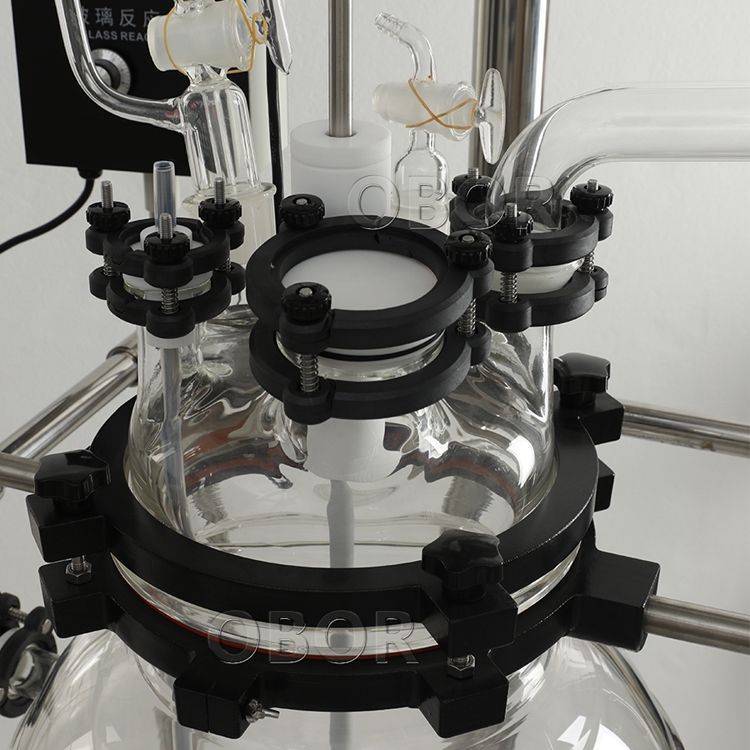

kettle lid With * six ports φ335mm | Material | Glass | ||

to stir | 60 flange | |||

Reflux/condenser | 50# ball mill joint/40# standard grinding port | |||

dripping funnel | 40# standard seam | |||

Filling valve | 34# standard seam | |||

thermometer tube | DN25 flange | |||

Kadokou | 80 flange | |||

PTFE hybrid seal | PTFE + oil seal + O-ring + bearing | |||

condenser | Spherical condenser, 0.95㎡ | |||

Reflux head | 1 littre | |||

constant pressure drop funnel | 2 liters | |||

Multifunctional manual valve | For filling, venting or filling with nitrogen | |||

thermometer tube | Stainless steel with PTFE | |||

*frame | stainless steel 304 | |||

*Drain valve | PTFE; no dead angle; inner diameter 23mm, outer diameter 32mm | |||

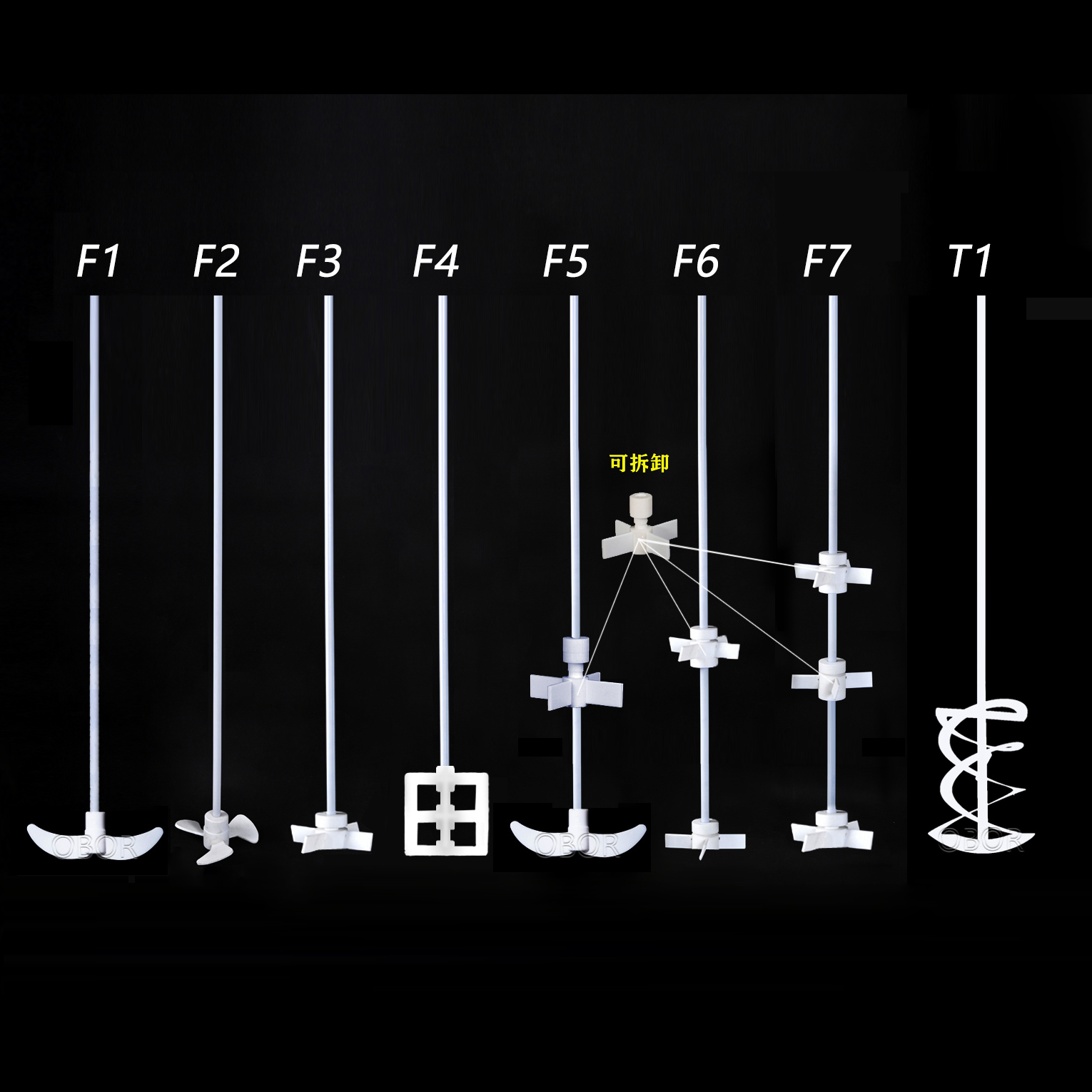

* Stirring blade type | PTFE, four blades, double layer | |||

In/out oil port | DN25 ball mill connection with 6' adapter | |||

Allen wrench | Some | |||

Machine size | 780L*730W*2450Hmm | |||

Remarks: The parameters with "*" are more selective; other parameters support customization | ||||

Details and Features

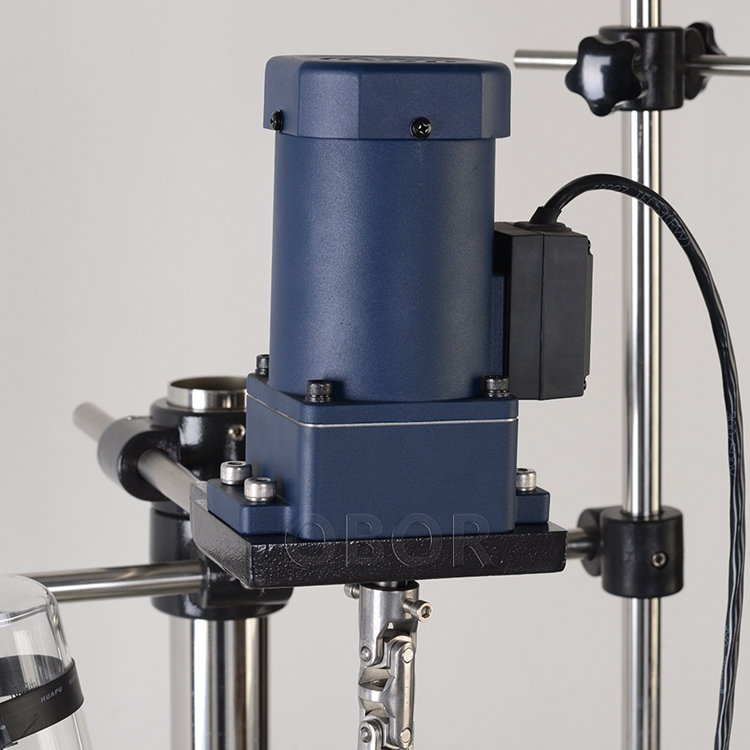

Driven by an AC variable frequency motor, the gear shaft is equipped with a reducer. The speed ratio is 1:3, and the stirring force is increased

High-efficiency double-layer serpentine coil condenser with large condensation area and high recovery efficiency

Anti-corrosion drain valve

multi-style stirring rod

optional features

Auxiliary equipment recommendation

While the materials are being mixed, the hot solution or cooling liquid is circulated through the jacket layer to achieve constant temperature heating or cooling. When the material is heated, the evaporation efficiency can be improved under vacuum conditions (need to connect a vacuum device). The condenser works with the chiller, and the cooling effect will be better. Before choosing a device, please let us know the purpose of use and the target temperature, so that we can recommend a suitable model for you.

VIEW MORE

YOU MAY LIKE