Industrial use fruit juice multiple-effect whey falling film vacuum evaporator milk

- $25000.00 /set

- 1 set

- Wenzhou Chinz Machinery Co., Ltd.

- Zhejiang, China

- Mr Chunsui Ye

PRODUCT DETAIL

| Processing: | Concentrator,Concentrator; | Brand Name: | CHINZ; |

| Weight: | KG; | Marketing Type: | Ordinary Product; |

| Place of Origin: | Zhejiang, China; | Payment Terms: | L/C,Western Union,T/T; |

| Condition: | New; | Processing Types: | tomato paste; |

| Power: | according to requirements; | Warranty: | 2 years; |

| Packaging Detail: | wooden case; | Package Preview: | ; |

| Local Service Location: | United Kingdom,United States,Thailand; | Core Components: | PLC,Bearing; |

| Certification: | CE; | Working pressure: | Vacuum pressure; |

| Warranty of core components: | 2 years; | Supply Ability: | 100 Sets per Quarter; |

| Voltage: | according to requirements; | Heating source: | Steam; |

| Showroom Location: | United States,Thailand; | System vacuum (MPa): | -0.1Mpa; |

| name: | multiple-effect whey falling film vacuum evaporator milk; | Applicable Industries: | Manufacturing Plant,Food & Beverage Factory,Food Shop; |

| Video outgoing-inspection: | Provided; | Machinery Test Report: | Provided; |

| Port: | ningbo/shanghai; | After-sales Service Provided: | Field installation, commissioning and training; |

| After Warranty Service: | Video technical support,Online support,Spare parts,Field maintenance and repair service; | Effect No.: | 1-effect, 2-effect,3-effect; |

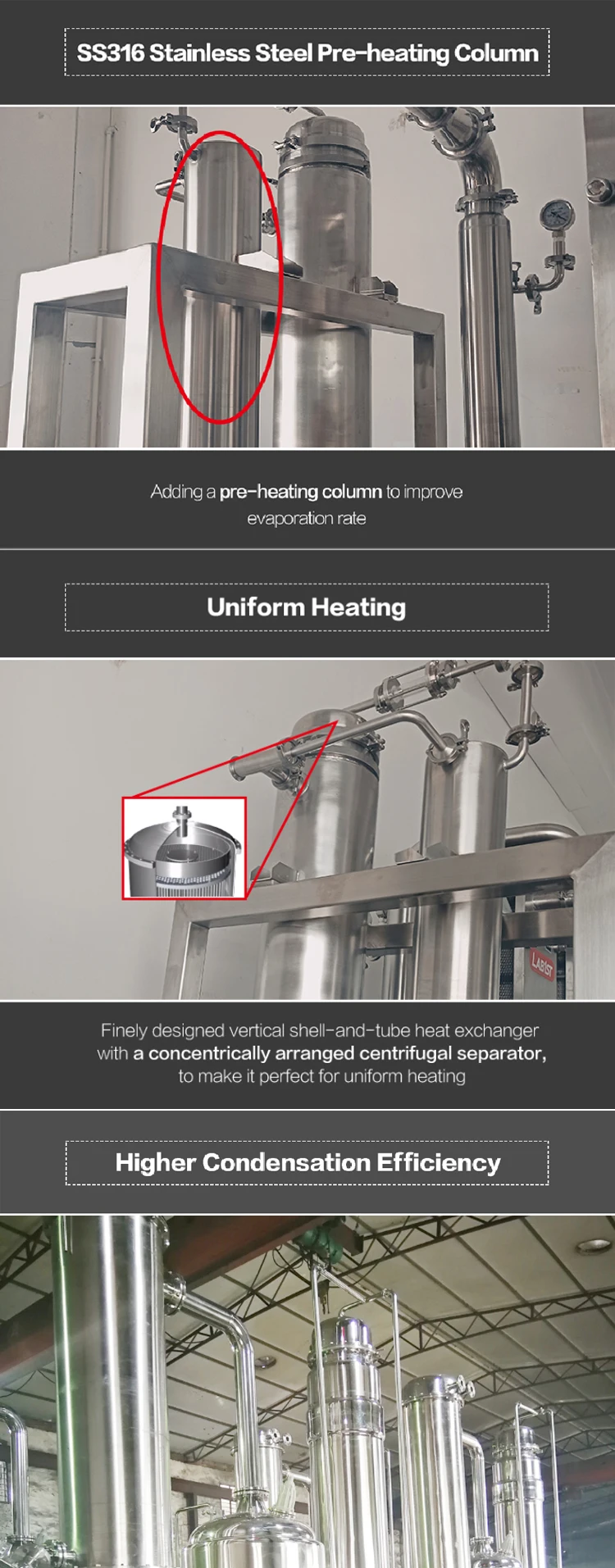

| Material: | SS304 or SS316L; | Application: | milk, juice; |

| Dimension(L*W*H): | According to capacity; | Key words: | vacuum evaporator milk; |

| Advantage: | High Efficency Durable; |

Products Description

Industrial use fruit juice multiple-effect whey falling film vacuum evaporator milk

Application:

The Falling film evaporator is applicable for dairy products, pharmacy, glucose, starch, chemical industry, xylose, citric acid, ammonium sulfate, biological engineering, environment engineering and waste liquid recovery and treatment etc.

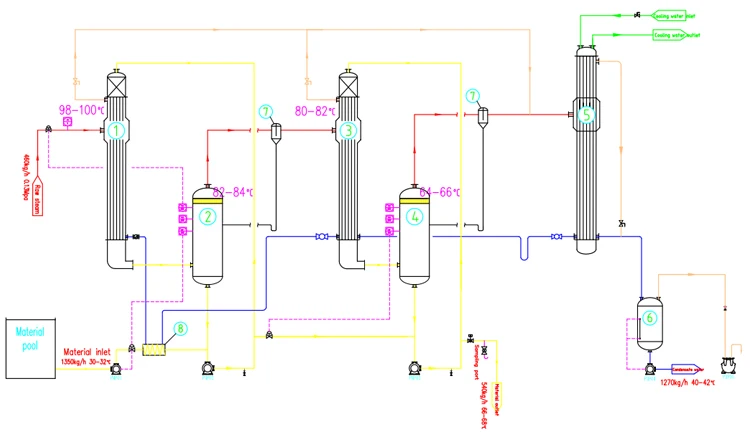

Composition:

It contains of 1st-effect, 2n-effect and 3rd-effect evaporators, 1st-effect, 2n-effect and 3rd-effect separators, pre-heater, condenser and hot pressure pump.

Equipment characteristics:

(1) Low evaporation consumption, 1Kg steam can evaporate 3.5Kg water.

(2) Low evaporation temperature. Part of twice steam can be inhaled into single-effect heater through spray type hot pressure pump. The high quality evaporation can be fully used and the evaporation temperature is low.

(3) Large concentration ratio with downward film type evaporation, which can make material liquid with viscosity be so easy to flow and evaporate, Hard to agglomerate with short concentration time. The concentration ratio can reach 1:5.

(4) The equipment can realize automatic production, intellectual system, which is conformity with GMP standard.

Features:

Ompact structure with small area.

The recover rate is around 97%.

It runs continuously.

The height is not high, it's easy to install and operate.

Modular design, maintenance is convenient.

Product Paramenters

NO | project | single effect evaporator | condenser | |

1 | material name | solution | ---- | |

2 | PH value | / | ---- | |

3 | discharge way | the fist effect discharge | ---- | |

4 | conduction oil heating | 0-300C | ||

5 | secondary steam temperature of each effect ℃ | 70±2 vapour phase | 70±2 vapour phase | |

6 | temperature of each effective feed liquid | 75±2 vapour phase | 50±2 vapour phase | |

7 | Each effect vacuum degree (-MPa) | ~0.05 | ~0.090 | |

8 | the boiling point of each efficent feed liquid increased ℃ | ~5 | ---- | |

9 | temperature difference loss of each effect ℃ | 2.0 | ---- | |

10 | heat loss per effect % | 8% | ---- | |

11 | each effect effectively heat transfer temperature difference ℃ | 30 | ---- | |

12 | evaporator circulation type of each effect | falling film circulation | ---- | |

13 | effective heat transfer coefficient W/m2。k | 1150 | ---- | |

Equipment Configuration List | ||||||||

NO | name | unit | qty | remark | ||||

1 | feeding pump | set | 1 | used for material transfer | ||||

2 | circulation pump | set | 1 | for falling film circulation and discharge | ||||

3 | condensate pump | set | 1 | condensate water extraction and transportation | ||||

4 | vacuum pump | set | 1 | 2BV type, ultimate vacuum degree -0.09Mpa | ||||

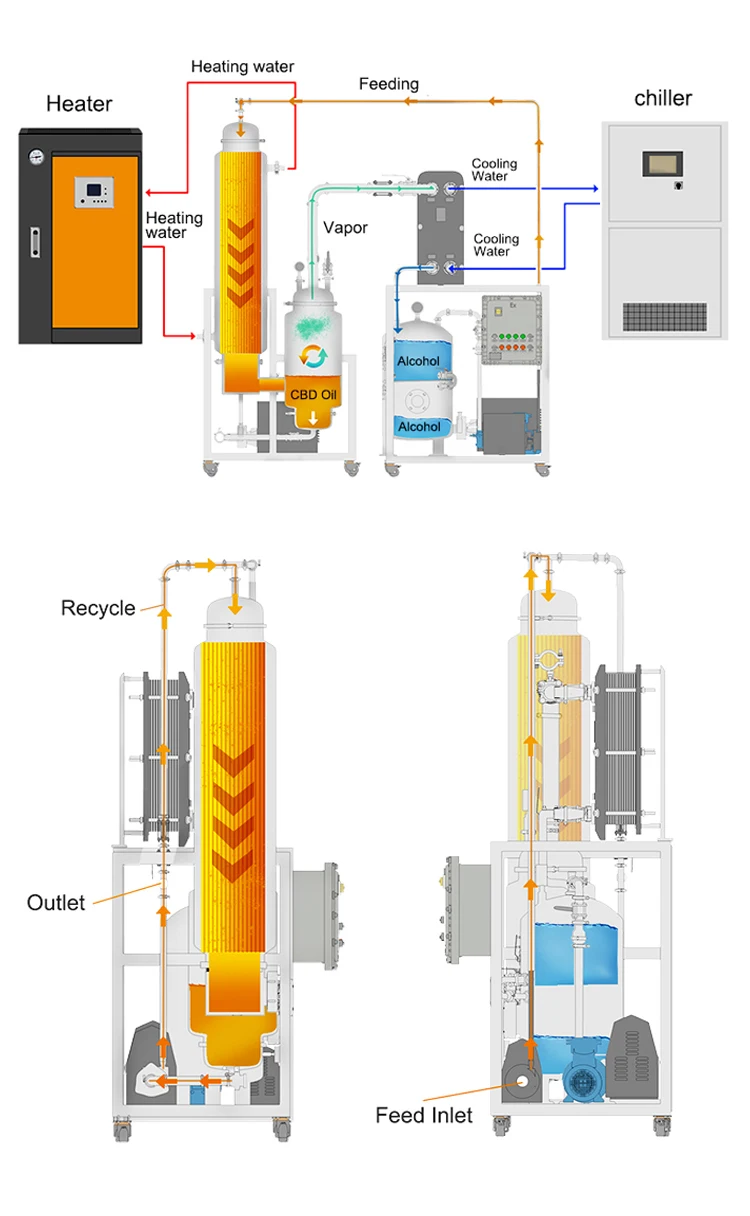

5 | heater | set | 1 | tubular structure, upper and lower heads can be disassembled for inspection | ||||

6 | condenser | set | 1 | detachable inspection | ||||

7 | condensate tank | set | 1 | store condensate water | ||||

8 | separation chamber | set | 1 | for vapor and liquid separation, with sight glass and light | ||||

9 | control cabinet | set | 1 | control of electrical components in equipment | ||||

10 | instrument | set | 1 | used for temperature, pressure and vacuum display | ||||

11 | pipe and valves | set | 1 | pipes are connected inside the evaporator | ||||

12 | supporting platform | set | 1 | |||||

Details Images

Product packaging

Company Profile

Wenzhou CHINZ Machinery Co.,Ltd is a high technology enterprise integrating biochemical pharmaceutical equipment, milk food and beverage industry. chemical industry and other hygiene level fluid equipment design manufacturing service. The enterprise has the subsidiary companies:Mechanical engineering research and development center,fluid equipment processing testing center,machinery manufacturing center.The company provides the advanced technology and services for the customers.

FAQ

1. Q : How can customer visiting our factory?

A : We are in Wenzhou city, Zhejiang Pr.China.which is very near to Shanghai.

From Shanghai,China to our city, it will take 1 hour by air, and 4 hours by fast train.

The name of airport is Wenzhou Longwan International Airport.

The name of fast train station is Wenzhou Nan train station.

And our factory is very close to airport only 15 minutes by car, and 1 hour by car from fast train station.

2. Q : How can customer know the processes of order?

A : We will take photo or video during manufacturing every two weeks to make customer clear about the order.

When goods is finished,we will take more detailed photos or video for inspect.

You can also come to our factory to inspect by yourself.

3. Q : Do you supply installation equipment in oversea?

A : Yes, if need, we can also send our installation engineer to your factory to help you do installation and testing.

And you need to provides round-trip ticket and accommodation for our engineer.

The extra salary of one installation engineer is 200USD/day.

4. Q : How to control quality?

A : All material we use has material certification.

Before any piece of equipment leaves CHINZ.

It goes through a complete quality and assurance control inspection.

This inspection assures your equipment meets all specifications and is in proper working order before it leaves our facility and arrives at your door.

5. Q : What is the shipment schedule?

A : We will send you photographs of your order being loaded into the shipping container at the factory.

The shipping container will generally leave port 3-4 days after loading.

We will send you a bill of lading and final statement of account within one week of that time. The bill of lading will include the shipping container numbers. You can track your shipping container.

Approximately 10 days prior to delivery, we will send you an ETA (Estimated Time of Arrival) notice from the shipping time.

Please remember that the listed delivery date is only an estimate, and is subject to port unloading schedules, customs processing, and the dictates of the local delivery truck company.

You will be directly contacted by the shipping company's local truck delivery services approximately 48 hours prior to the date of delivery to schedule a delivery time.

If you need to delay the final delivery, there will be a "pull" fee of approximately $100, and a storage fee of approximately $150 per shipping container per day.

6. Q : Which material are the equipment made of?

A : Stainless steel 304/ stainless steel 316/ Ti

VIEW MORE

YOU MAY LIKE