Low price High quality CNC V groover Machine V grooving machine for sale

- $30000.00 /set

- 1 set

- JUGAO CNC MACHINE JIANGSU CO LTD

- Jiangsu, China

- Mr Gary Gao

| Showroom Location: | None; | Condition: | New; |

| Marketing Type: | Ordinary Product; | Color: | optional V grooving machine; |

| Core Components: | PLC,Motor,Gear; | Deviation of Length: | +/-0.05mm; |

| Max Cutting speed: | 65 m/min; | Place of Origin: | Jiangsu, China; |

| Applicable Industries: | Construction works ,Building Material Shops,Advertising Company,Machinery Repair Shops,Manufacturing Plant; | Machinery Test Report: | Provided; |

| Packaging Detail: | Low price High quality CNC V groover Machine V grooving machine for sale,Wrapped by plastic films and fixed by steel wires in the containers; | Weight (KG): | 8000; |

| Locating precision: | +/-0.05mm; | Supply Ability: | 60 Sets per Month V Grooving Machine For Sale; |

| Warranty of core components: | 1 Year; | Name: | V grooving machine; |

| Payment Terms: | L/C,Western Union,D/P,D/A,T/T,MoneyGram; | Power (kW): | 7.5; |

| Warranty: | 1 Year; | Port: | ShangHai; |

| Main motor power: | 4.4 kw; | Key Selling Points: | Easy to Operate; |

| Self-assessment: | China First Class V Grooving Machine; | Min.grooving distance: | 8 mm; |

| Thickness of grooving plate: | 0.5 ~ 6 mm; | Control Axes: | Y + X+ R-axis; |

| Video outgoing-inspection: | Provided; |

Low price High quality CNC V groover Machine V grooving machine for sale

This equipment is fully CNC V Groover Machine for metal sheet. It adopts advanced CNC system and innovative design with the advantages of high processing precision, simple operation, no noise, no vibration and so on. It is widely used in the sheet metal V-groove, U-groove and other irregular groove processing (including stainless steel, aluminum, aluminum plate, copper, iron, plastic, wood, acrylic panels and other special plates).Particularly.It is applicable to the V-groove processing of sheet metal before bending .

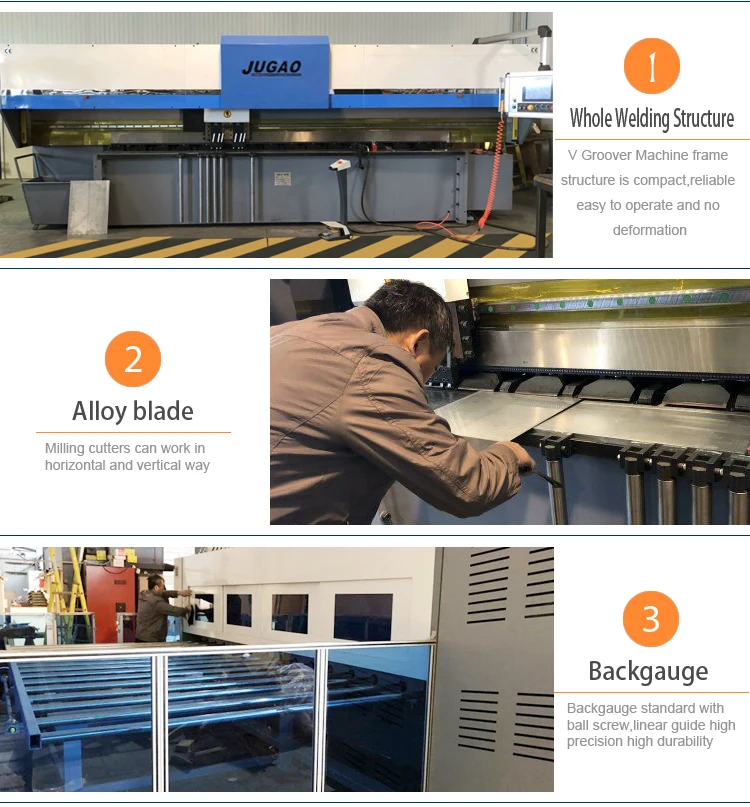

Structural Features

- The body is a full steel plate welded structure, tempering aging, small deformation;

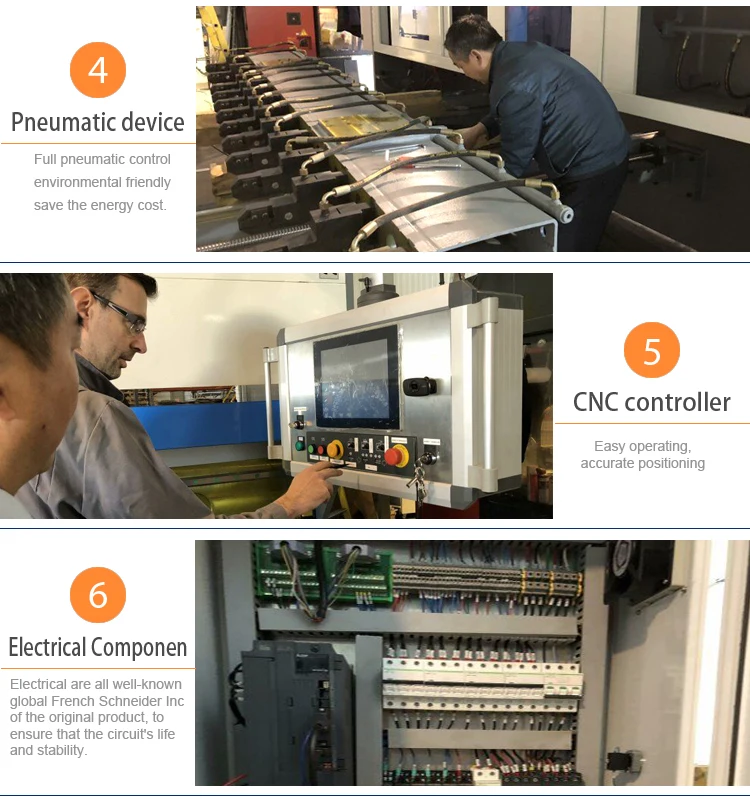

- Using CNC (CNC) device, automatic processing;

-

Using air pressure device, clamping, release full automation;

-

The underside of the planer blade can be adjusted after wear to improve the service life of the whole machine;

- Using five planers to work together, the efficiency of planing is high;

- There is a detachable bracket in front of the table to facilitate the processing of long workpieces;

-

Full servo motor, accurate positioning, high precision;

- All operating systems of the machine are precisely combined with electro-pneumatics, which is easy to operate, flexible in action, high in efficiency, low in noise, and free of environmental pollution.

Product parameters

| Model | Max.grooving thickness(mm) | Min.grooving thickness(mm) | Cutting speed m/min(max) | Knife rest resolutiong(mm) | Positioning accuracy(mm) | Hydraulic system(Mpa) | Machine size(MM) |

| 1220X6000 | 6 | 0.5 | 65 | 0.001 | ±0.01 | 6-8 | 8200*2350*1900 |

| 1220X3200 | 6 | 0.5 | 65 | 0.001 | ±0.01 | 6-8 | 4700*2350*1950 |

| 1220X4000 | 6 | 0.5 | 65 | 0.001 | ±0.01 | 6-8 | 5500*2350*1950 |

| 1500X4000 | 6 | 0.5 | 65 | 0.001 | ±0.01 | 6-8 | 5500*2650*1950 |

| 1500X6000 | 6 | 0.5 | 65 | 0.001 | ±0.01 | 6-8 | 8200*2650*1980 |

Guarantee period:

Our product quality guarantee period is 12 months from B/L date. During guarantee period, we will provide spare parts without any charge in case of quality discrepancy caused by us. If the malfunctions are caused by customers’ incorrect operations, we will provide customers spare parts at cost price. We also can offer flexible extended warranties according to the actual situation.

After-sales services:

Our engineer can go to your factory for installation and showing operation details on condition of you provide the round-trip air tickets, visa formalities, food and accommodation. In turn, your engineers can come to our factory for learning the installation, operation and maintenance for free.

Why Choose Us:

1. We will run the machine for a few days, and use your materials to do the test. Only guarantee the machine shows best performance, and then we will ship out.

2. Our elite teams can provide you professional, customized, and all-round services around the clock. If you need any help, contact us by WHATSAPP, Skype, Email or Telephone.

How can we provide you efficient services (metal processing solution):

There are Three Steps as following:

1. Gather your requirements based on your real working situation.

2. Analyze your information and provide our feedback.

3. Offer options based on your specific needs. For instance, reg. standard products, we can offer professional recommendations; reg. non-standard products, we can offer professional designing.

|

|