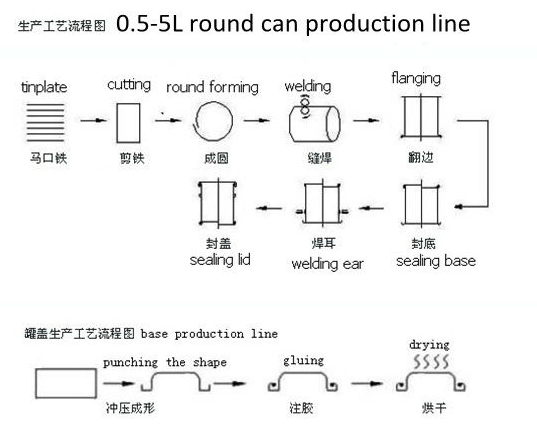

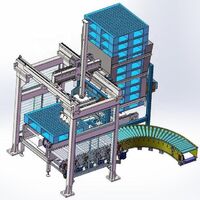

Metal can end making machine/can end production line

- $1500.00 /set

- 1 set

- Jiujiang Xingda Can Machinery Co., Ltd.

- Jiangxi, China

- Mr weiheng xu

| After-sales service provided: | online support | Automatic level: | semi-automatic |

| Materials used for packaging: | Metal | type: | Packaging line |

| weight: | 150 kg | Core component warranty: | 1 year |

| usage: | Tin can lid edge crimping | Dimensions (L*W*H): | Model |

| Health status: | new | Video shipment inspection: | if |

| brand: | Xingda | aspect: | 740*1100*590mm |

| Mechanical test report: | if | Applicable industries: | can factory |

| Packaging Details: | Plywood, sea freight standard packing | port: | China's main ports |

| Applicable thickness: | Maximum≤0.5mm | After warranty service: | Video technical support |

| Showroom location: | not any | Voltage: | 380V 50HZ |

| application: | chemical, food | Main selling points: | easy to operate |

| Origin: | Jiangxi, China | Marketing Type: | New Products 2020 |

| Supply capacity: | 200 sets per month | Warranty: | 1 year |

| capacity: | 20-30 pieces/minute | Core components: | engine |

| payment terms: | L/C, Western Union, T/T | Driver type: | electrical |

| Workers need to: | 7-8 | type of packaging: | barreled, canned |

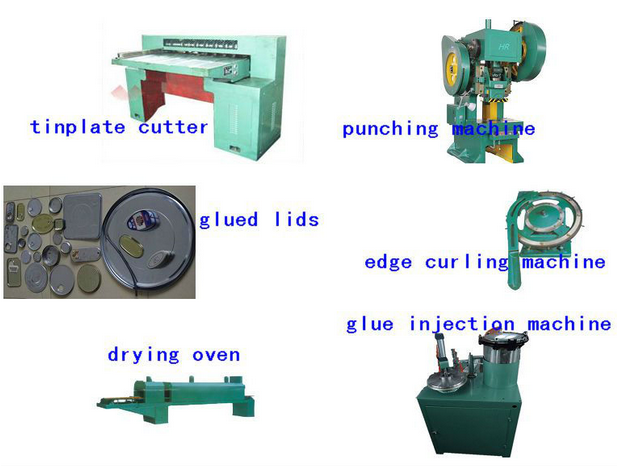

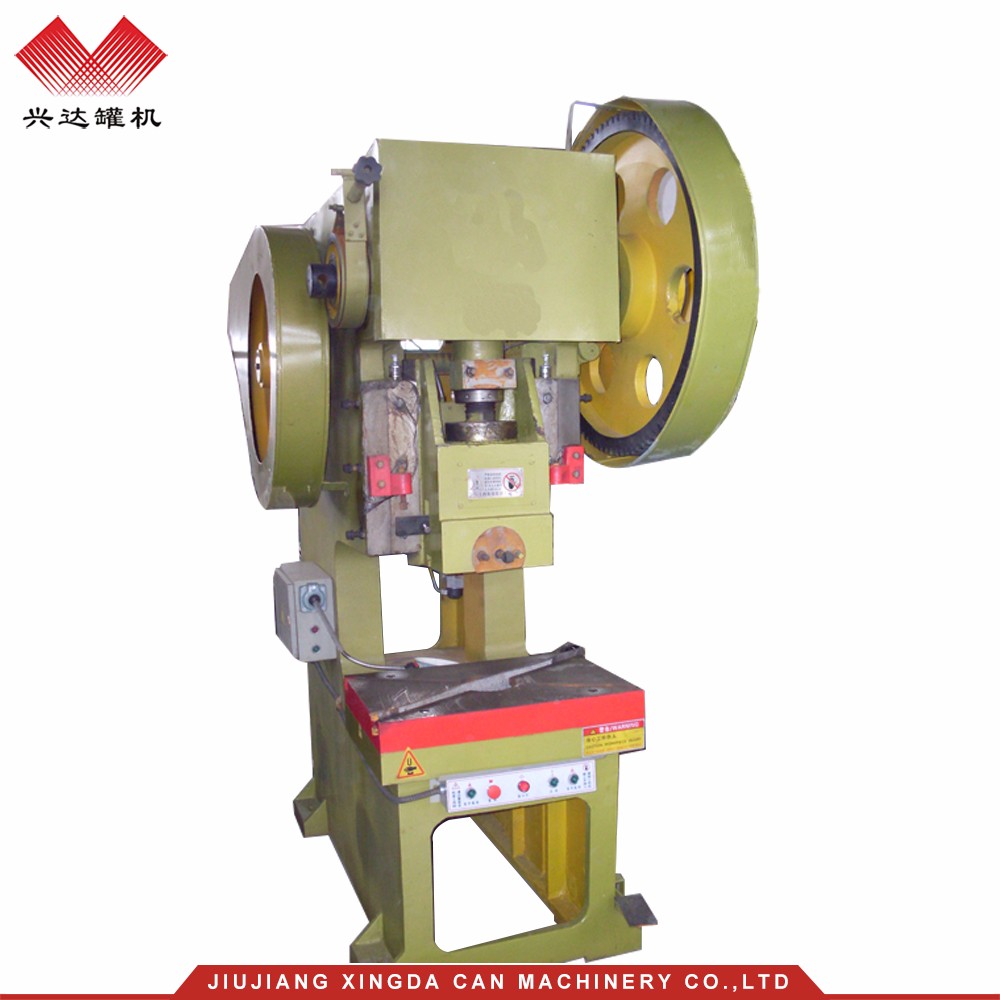

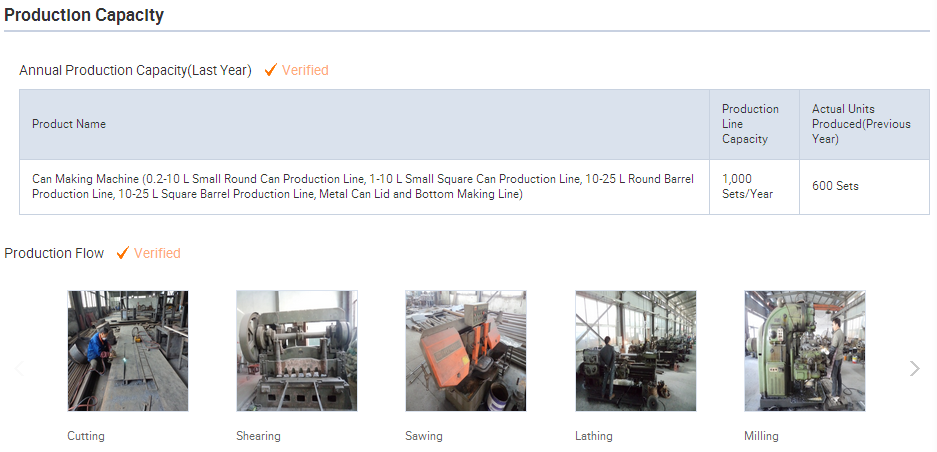

2B3 round edge machine

Diameter range: 52-108 108-176 176-300

usage:

Curled lid and bottom edge.

1) This canning production line is used to produce various small round cans, such as tea cans, food cans, glue/glue cans, ink cans, craft cans, etc.

2) If the customer wants to make cans of other sizes, only need to change the machine mold

main feature

1). More than 20 years of experience and reputation at home and abroad;

2). Quality assurance, high-quality after-sales service, reasonable price;

3). Reliable and safe control, convenient operation and maintenance;

4). Equipped with man-machine interface and PLC; Adopt digital control technology;

5). Fully automatic, semi-automatic, multi-mode, suitable for cans of different shapes and sizes.

6). Convenient transportation around the airport, railway and port.

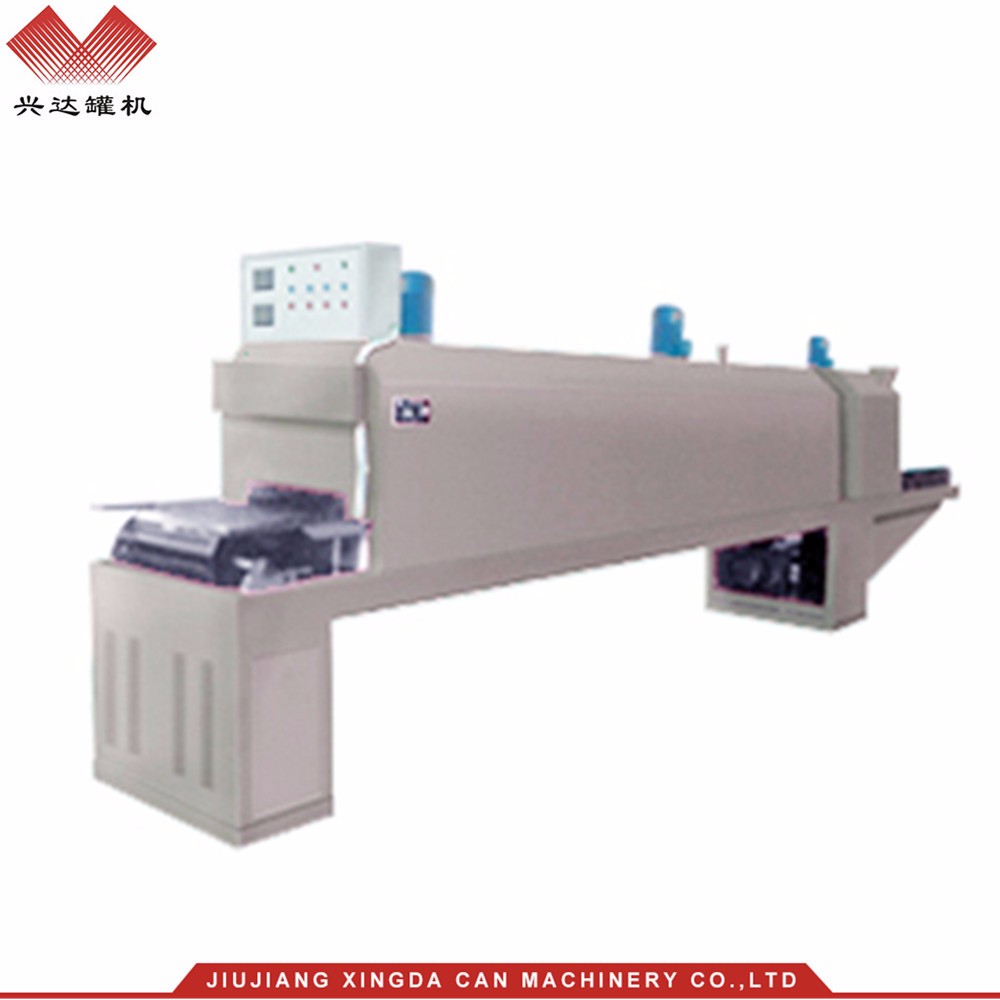

Canning line

Can end production line

Suitable for the following tanks

pre-sale service

* Inquiry and consultation support.

* Sample testing support.

* Check out our factory.

After-sales service

* Training how to install the machine, training how to use the machine.

* Engineers are available to service machinery overseas.

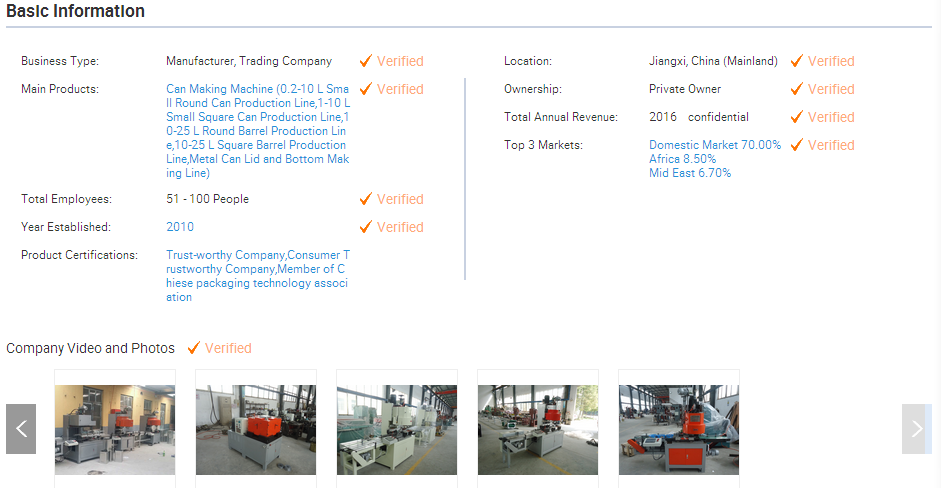

Jiujiang Xingda Can Machinery Co., Ltd.

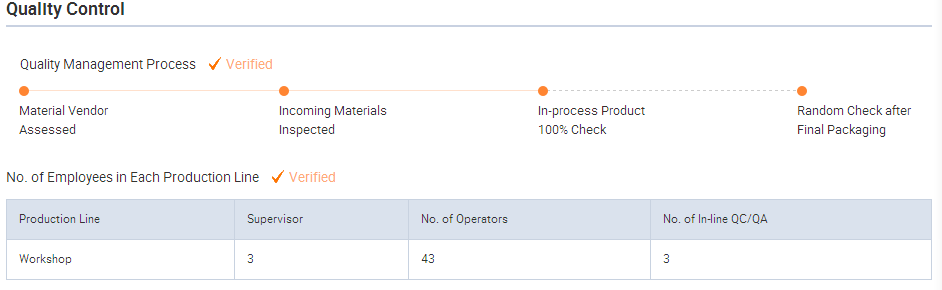

The company was established in 1994, specializing in semi-automatic and automatic metal can making machines/complete production lines for chemical, food, industrial, paint can making, etc. Our products include: sheet metal cutting machines, can rolling machines, seam welding machines, flanging machines, sealing machines, molds and can end/end making machines, etc.

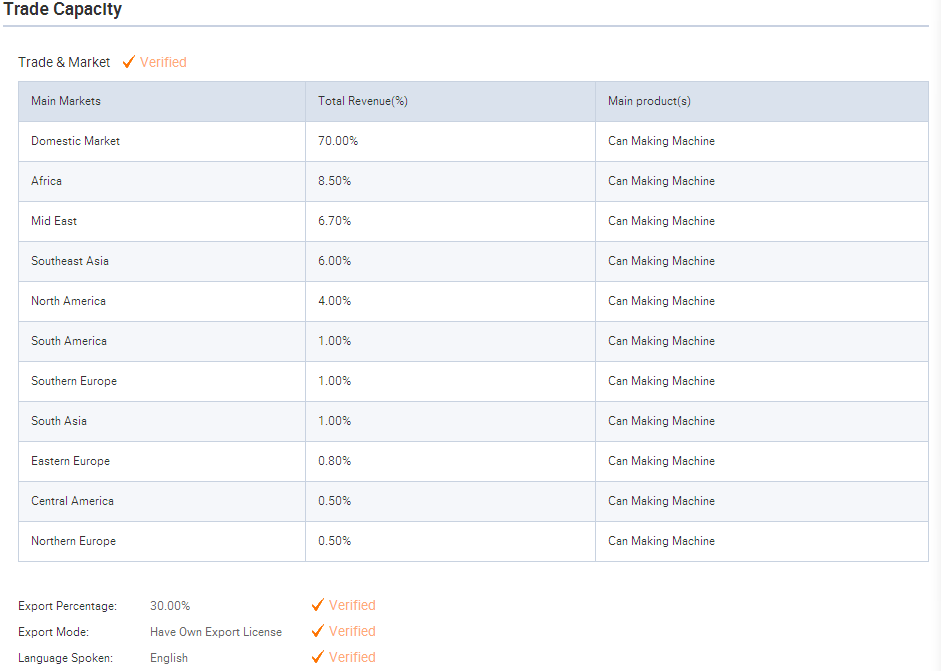

Our machines have been exported to many countries, such as Saudi Arabia, UAE, Iraq, Russia, Canada, Greece, Egypt, Tunisia, Morocco, South Africa, Ethiopia, Kyrgyzstan, Malaysia, Indonesia, Peru, Myanmar and so on.