SUS304 Material Manual Cip Cleaning System Equipment For Beverage Plant

- $15000.00 / 1 - 1 sets

$13000.00 / 2 - 9 sets

$10000.00 / >=10 sets - 1 set

- Zhangjiagang Jinlonghai Mechanical Equipment Co., Ltd.

- Jiangsu, China

- Mr Alex yang

PRODUCT DETAIL

| Capacity: | Customized; | Local Service Location: | Canada,Turkey,United Kingdom,United States,Italy,France,Germany,Viet Nam,Philippines,Brazil,Peru,Saudi Arabia,Indonesia,Pakistan,Mexico,Russia,Spain,Thailand,Japan,Malaysia,Australia,Morocco,Argentina,South Korea,Chile,UAE,Colombia,Algeria,Sri Lanka,Romania,South Africa,Kazakhstan,Ukraine,Kyrgyzstan,Nigeria,Uzbekistan,Tajikistan; |

| Package Preview: | ; | Automatic Grade: | Auto; |

| Name: | Automatic CIP Cleaning System; | Certification: | CE ISO; |

| Machinery Test Report: | Provided; | Applicable Industries: | Food & Beverage Factory; |

| Application: | food beverage area; | Processing: | Washer; |

| Weight: | Customized,900KG; | Dimension(L*W*H): | Customized; |

| After-sales service: | All life; | Marketing Type: | Ordinary Product; |

| Processing Types: | Liquid with concentrated acid and alkali; | Power: | 30KW; |

| Supply Ability: | 200 Set/Sets per Month; | Voltage: | 220/380V 50/60Hz 3PH; |

| Material: | Stainless Steel 304; | Usage: | Cleaning concentrated acid and alkali liquid; |

| Warranty of core components: | 2 years; | Packaging Detail: | Wooden box; |

| Video outgoing-inspection: | Provided; | Place of Origin: | Jiangsu China; |

| Condition: | New; | Payment Terms: | L/C,Western Union,D/P,D/A,T/T,MoneyGram,Cash; |

| After-sales Service Provided: | Field installation, commissioning and training; | Warranty: | 2 years,2 years; |

| Showroom Location: | Canada,Turkey,United Kingdom,United States,Italy,France,Germany,Viet Nam,Philippines,Brazil,Peru,Saudi Arabia,Indonesia,Pakistan,Mexico,Russia,Spain,Thailand,Morocco,Argentina,South Korea,Chile,UAE,Colombia,Algeria,Sri Lanka,Romania,South Africa,Kazakhstan,Ukraine,Kyrgyzstan,Nigeria,Uzbekistan,Tajikistan,Japan,Malaysia,Australia; | After Warranty Service: | Video technical support,Online support,Spare parts,Field maintenance and repair service; |

| Port: | Shanghai port; | Core Components: | Motor; |

| Brand Name: | JLH; | Operating: | auto; |

Product Overview

CIP Cleaning System

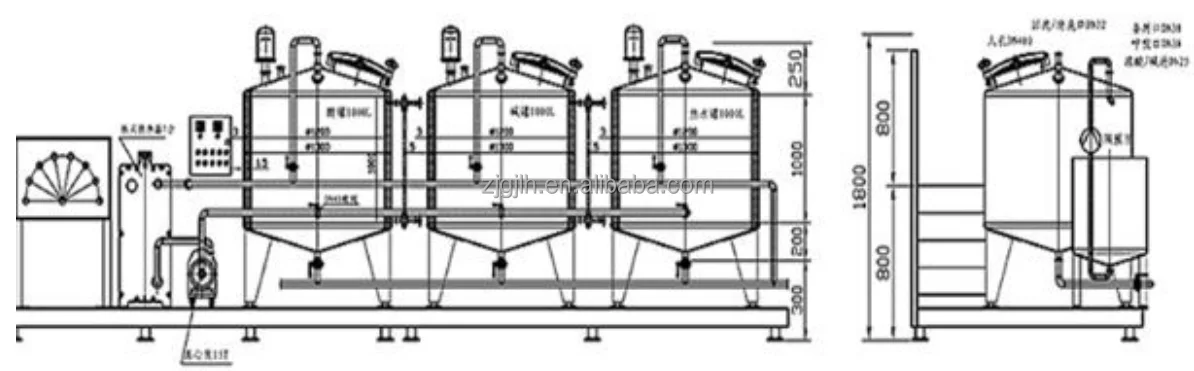

CIP cleaning system is used for cleaning the filling system and various tanks and containers in the factory.

The advantages of the system are reducing chemical consumption and energy consumption. It is simple to operate, less maintenance work and long service life. PLC is used to realize full automation operation and touch screen to realize friendly human-computer interface. Remote maintenance system can be selected. You can customize the proprietary cleaning procedures for each customer, or customize the equipment and components according to the customer's requirements.

CIP station can achieve the goal of cold or hot cleaning by using various cleaning agents, so as to remove mineral and biological residues and other dirt. Finally, the target parts were sterilized and sterilized.

CIP cleaning technology is mature in brewing, beverage, food and chemical industries and biotechnology and can be used anywhere that requires full automatic and reliable cleaning and disinfection.

CIP system design, overall dimension and function design are closely communicated with customers, and provide safe and economical CIP system according to their specific needs.

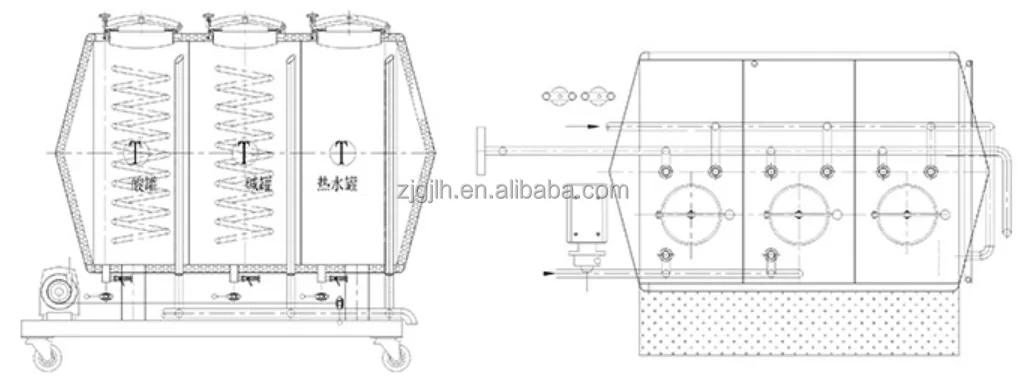

CIP system is designed and matched with a storage tank for cleaning agent or a circuit for recycling CIP cleaning solution according to different cleaning objectives. Different cleaning processes and procedures can be stored in the control system, and the system runs automatically according to the parameters. According to the size and characteristics of each cleaning object, the appropriate flow rate is selected, and the conductivity, temperature and flow rate of each CIP circuit are monitored. The system is equipped with a device for automatically replenishing the concentration of cleaning agent. Optimized technology and equipment can prevent the mixture of different cleaning agents or any detergent from polluting sterile water or products. The CIP system can be controlled by the local PLC or the process control system of the touch panel.

High standard hygiene design, all common cleaners in the beverage and chemical pharmaceutical industries can be used for CIP cleaning.

Welcome to contact me for more details

WhatsApp/Wechat/Mobile---008613917995074

[email protected]

WhatsApp/Wechat/Mobile---008613917995074

[email protected]

FEATURES AT A GLANCE

1.Equipment material:Stainless Steel 304.

2.Cleaning strong acid and alkali liquid.

3.Equipment technology is mature, cleaning thoroughly.

4.Suitable for yogurt, water, beer and other production lines.

PRODUCT SPECIFICATIONS

Model | JLH-CIP-0.5 | JLH-CIP-0.8

| JLH-CIP-1.0 | ||

Acid tank | 500L | 1000L | 1500L | ||

Alkali tank | 500L | 1000L | 1500L | ||

Water pot | 500L | 1000L | 1500L | ||

Pump flow | 10m*3/h | 15m*3/h | 20m*3/h | ||

Pump lift | 36m | 36m | 36m | ||

Pump power | 2.2kw | 4kw | 5.5kw | ||

Heating plate | 6m*2 | 8m*2 | 10m*2 | ||

Dimension(L*W*H) | 2900*1000*1700mm | 3000*1200*1850mm | 3200*1400*2000mm | ||

Equipment Weight | 350KG | 420KG | 480KG | ||

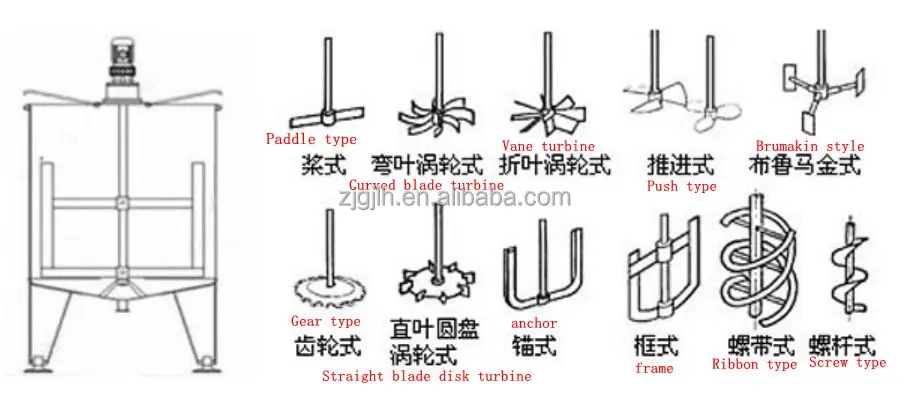

PRODUCT CONFIGURATION

SALES AND SERVICE NETWORK

After-Sales Service

In order to better serve the needs of users, do a good job in after-sales service, our factory in line with the spirit of "all the pursuit of high quality, high quality, customer satisfaction for the purpose". We make the following promises to the users based on the principle of "considerate service and reliable product quality":

1. Product quality commitment: the manufacturing and testing of products are in line with national standards, and all indicators of products meet the requirements of customers.

2. Delivery commitment: deliver the goods to the designated place according to the time required by the customer. If the customer has special requirements and needs to complete the project ahead of time, please negotiate with us to save the construction period.

3. Provide after-sales service for life. Outside the warranty period, only the cost of spare parts is charged for maintenance, and no labor technology and service fees are charged

4. The factory will arrange relevant professionals to teach the correct and timely use. 5. In order to prevent users from causing unnecessary losses due to improper use, the company will send relevant technical personnel to the grassroots level to provide technical guidance to users in the process of product use. Ensure the correct use of the product.

6. In order to provide better after-sales service, we will receive feedback from users in time, make feedback records, and provide solutions. If there is a need for on-site guidance, the factory will arrange technical personnel to the designated place for timely guidance.

Successful Project

SIMILAR PRODUCTS

FAQ

Customers: Are you a trading company or a manufacturer?

Factory: We are a manufacturer, we supply the factory price with good quality, welcome to visit.

Customers: What's your guarantee or the warranty of the quality if we buy your machines?

Factory: We offer you the high quality machines with one year guarantee and supply long life technical support.

Customers: When can I get my machines after I paid?

Factory: The delivery time is based on the exact machine you confirmed.

Customers: How can I install my machines when they arrive?

Factory: We will send our engineers to your factory to install the machines and train your staffs how to operate the machines.

Customers: How about the spare parts?

Factory: After we deal with all the things, we will offer you a spare parts list for you refer.

Packing&Shipping

Main types of marine transportation

Company Profile

1. This machine is mainly used for cleaning and sterilization of glass bottles and polyester bottles before filling. It is suitable for washing disposable polyester bottles with a little floating dust and glass bottles cleaned by bottle washing machine.

2. The automatic control system composed of advanced electric and gas components makes the whole washing process fully automatic, which can ensure that the machine can wash bottles reliably at high speed and continuous state, so it has high production efficiency. This machine is a rotary, full-automatic special equipment which uses flushing liquid and sterile compressed air to spray the inner cavity of bottle.

3. The flushing system is designed with water circulation and filtration device to make the flushing water be recycled and reduce energy consumption.

4. The working mode of the bottle flushing nozzle is designed with one fixed type and two kinds of follow-up lifting type for customers to choose. The bottle flushing process is reasonable and the residual liquid is less.

5. Simple operation, with a variety of safety protection devices to ensure the safety of operators and equipment.

6. The main motor and bottle conveying belt adopt frequency regulation technology.

7. The main electrical components are composed of imported components, and the "man-machine interface" can be configured for customers to choose, so as to effectively ensure the stability and durability of the product.

VIEW MORE

YOU MAY LIKE