Semi-automatic rotary glass bottle washing machine/glass bottle brushing machine/glass bottle de-labeling machine

- $2000.00 /set

- 1 set

- Zhangjiagang Technology Star Machinery Co., Ltd.

- Jiangsu, China

- Mr Jiacai Wang

| Material: | sus304 | Applicable industries: | Food and Beverage Factory |

| Voltage: | 220V 50HZ | Showroom location: | Pakistan |

| place of origin; place of origin: | Jiangsu, China | Dimensions (L*W*H): | 1120*845*1350mm |

| Processing: | washer | Core Components Warranty: | 3 years |

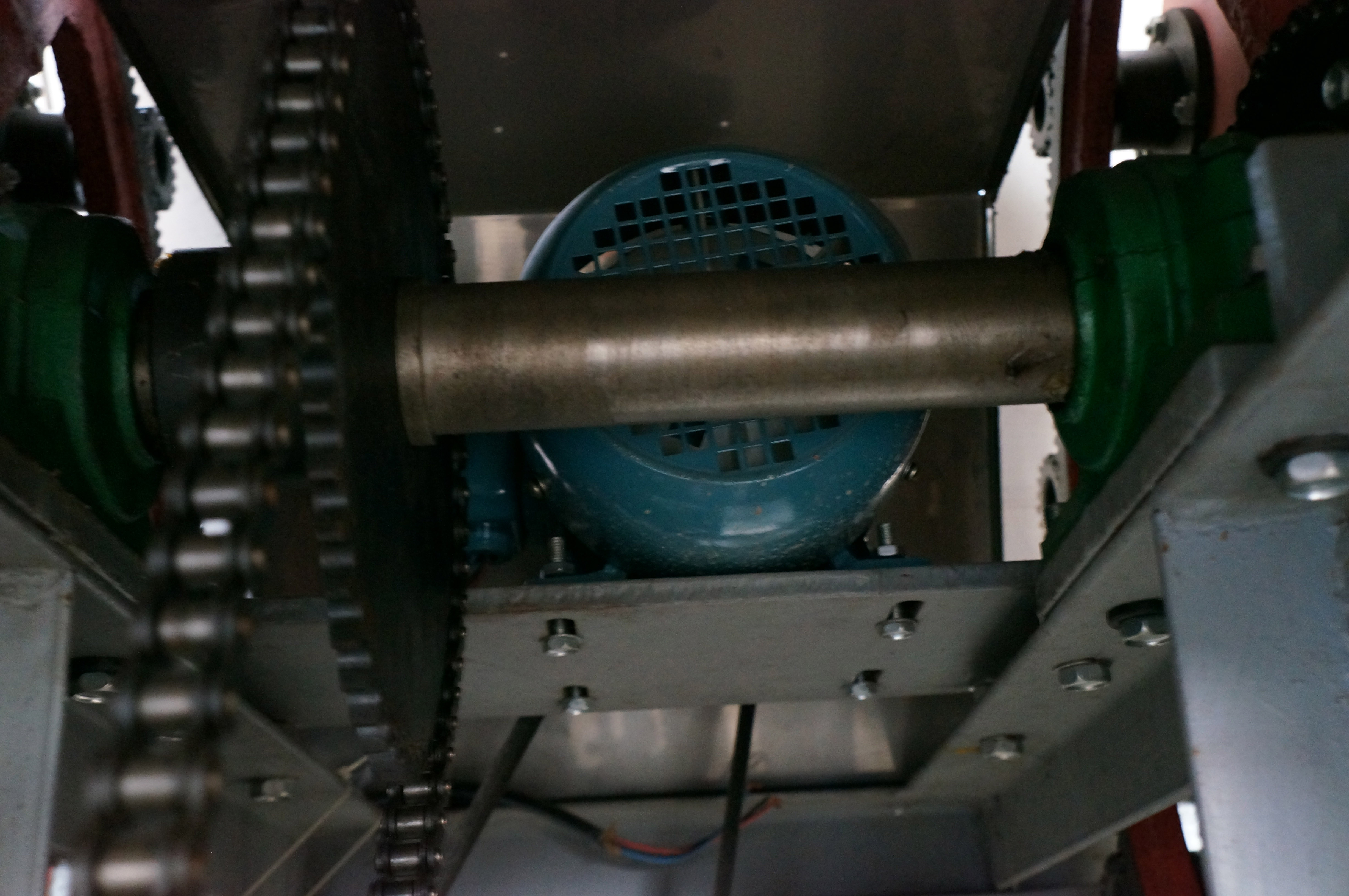

| Core components: | engine, bearing | product name: | Semi-automatic bottle washer |

| weight: | 500kg | Bottle type: | glass bottle |

| payment terms: | letter of credit, wire transfer | After-sales service provided: | Engineers can repair machinery overseas |

| color: | silver | Warranty: | 12 months, 1 year |

| Certification: | ISO CE | Health status: | new |

| Marketing Type: | New Products 2020 | capacity: | 1000-3000 bottles/hour |

| brand: | technology satellite | Supply capacity: | 20 sets per month |

| Processing Type: | glass bottle | Video external inspection: | if |

| port: | Shanghai | Packaging Details: | Film packaging and wood packaging |

| Mechanical test report: | if | usage: | wine industry |

| strength: | 1.8 |

Glass bottle washing machine

This washing machine is especially suitable for brushing inside and outside of round recycled glass bottles, especially for brushing inside. Can also be used to remove tear-off labels; bottles should be soaked in water for a period of time before being washed in recycled bottles. Bottles should be filled with water, wine, juice, or other beverage washes. The material is high-quality stainless steel, which meets food-grade requirements. The same bottle neck, one machine is suitable for bottles of different specifications. The structure is simple and beautiful. Easy operation and maintenance, high efficiency.

work process

Soak the bottle in water first, after a while, connect the water source and power supply through the water pipe, the worker inserts the bottle into the brush position, turns on the switch, the bottle will rotate with the dial; the brush rotates inside the bottle to clean the inside of the bottle; the manual is removed from the bottle Take it out.

Internal brush

Polymer brush, durable and effective in removing dirt from the bottle.

Outer brush (remove labels)

Brush the outside three times, can effectively remove the label on the bottle.

1. Significantly reduce maintenance costs

3. Easy rust wash down with Gates stainless steel hardware

Specification | ||||||

Model | XP-24 | |||||

capacity | 1000-4000 times/hour | |||||

bottle length range | 140-400mm | |||||

bottle diameter | 12-60mm | |||||

bottle diameter | 50-100mm | |||||

motor | 4kw/380v | |||||

Machine size | 151.5*112.3*1400mm | |||||

machine weight | 200KG | |||||