Screw Machine Price Automatic/Machine Production Screws

- $5000.00 /set

- 1 set

- Xuchang Hongshuo Machinery Co., Ltd.

- Henan, China

- Mr

PRODUCT DETAIL

| Mechanical test report: | if | Screw length: | 18-200mm |

| Type of machine: | Machined Screws | Voltage: | 380V/220V/customizable |

| Production capacity: | 100% | Package preview: | |

| payment terms: | L/C, Western Union, T/T, MoneyGram | Main selling points: | multifunctional |

| Showroom location: | not any | Warranty: | 2 years |

| port: | Qingdao Port | brand: | Hong Shuo |

| Video shipment inspection: | if | Raw material 2: | stainless steel coil |

| weight: | 2000 | Screw diameter: | 3-8mm |

| Model: | M3-18A/B | color: | customer request |

| Supply capacity: | 200 sets per month | application: | put up |

| Core component warranty: | 2 years | Health status: | new |

| Origin: | China | usage: | Make different sizes and types of screws |

| Packaging Details: | By wooden case or by sea. Machined Screws | control method: | CNC automatic type |

| Marketing Type: | normal product | Applicable industries: | Building material stores, manufacturing plants, construction projects |

| Core components: | PLC, engine, bearing, gearbox, motor, pressure vessel, gear, pump | lubricating: | Machinery oil |

| Raw material one: | Annealing coil |

Screw Machine Price Automatic/Machine Production Screws

Product Description

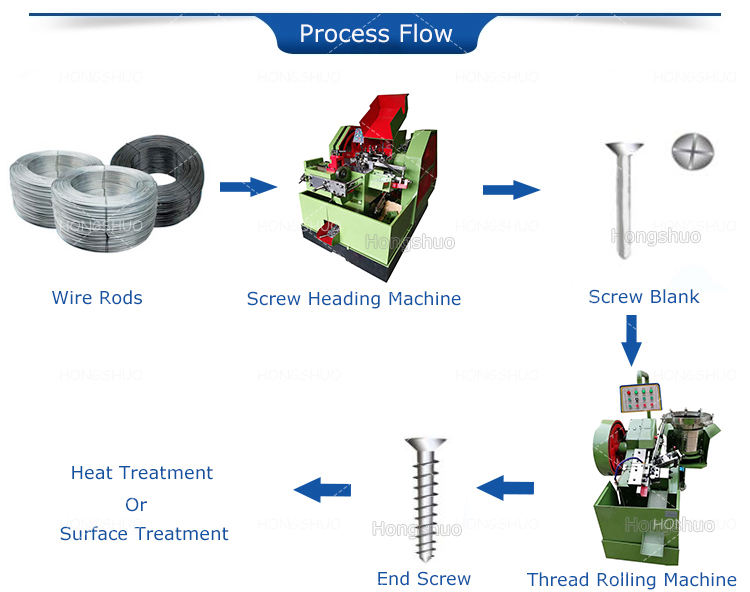

Wire rod--screw making machine--thread rolling machine--finished screw.

machine photo

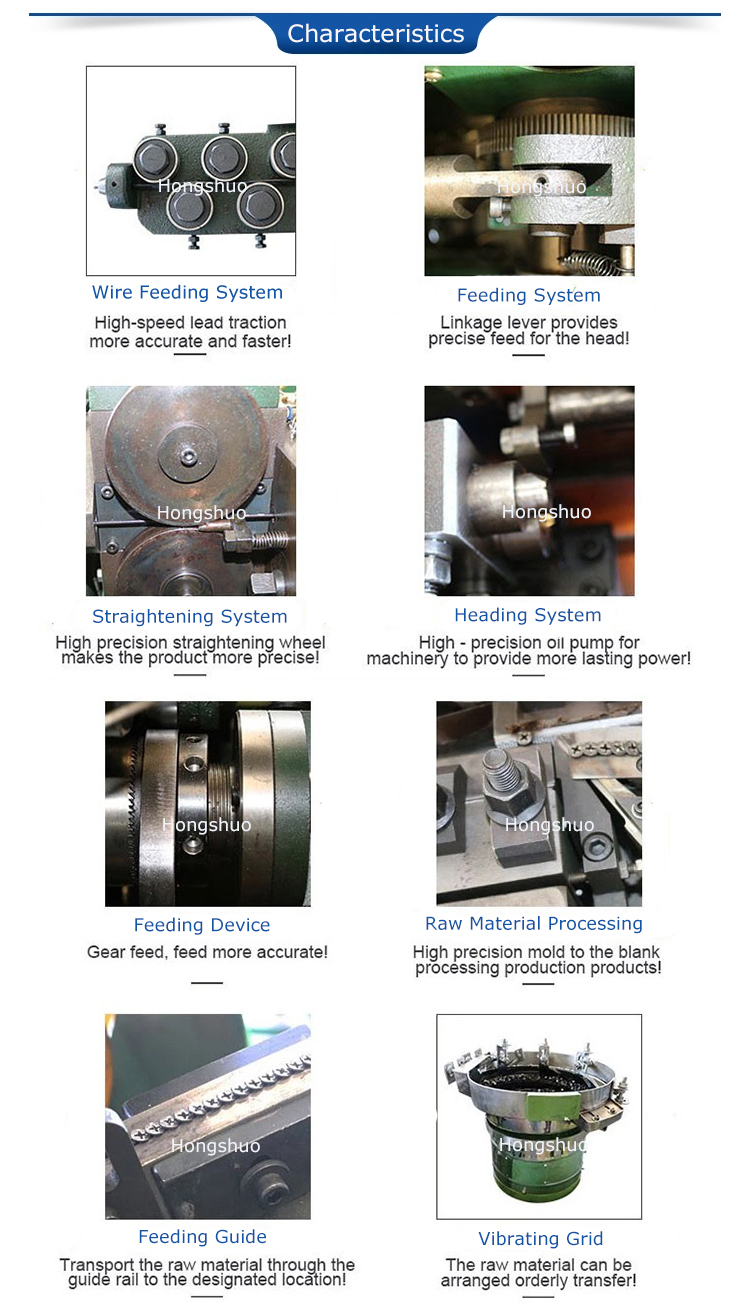

Step 1: Screw Making Machine

1. Wire feeding system: high-speed traction, more precise and faster

2. Feeding system: precise feeding with connecting rod feeding head

3. Straightening system: High-precision straightening wheels make the product more accurate

4. Heading system: High-precision mechanical oil pump provides more durable power

2. Feeding system: precise feeding with connecting rod feeding head

3. Straightening system: High-precision straightening wheels make the product more accurate

4. Heading system: High-precision mechanical oil pump provides more durable power

Model | maximum. Screw diameter(mm) | maximum. Screw length(mm) | capacity (pcs/min) | engine (kilowatt) | weight (Ton) | Overall size (m) |

M3-18A/B | 3 | 18 | 160-180 | 0.75/0.37 | 0.6 | 1.3*0.75*0.9 |

M3-28A/B | 3 | 28 | 160-180 | 0.75/0.37 | 0.6 | 1.3*0.75*0.9 |

M4-28B | 4 | 28 | 120-160 | 1.5/0.37 | 0.97 | 1.5*0.9*0.9 |

M4-28D | 4.5 | 28 | 180-200 | 1.5/0.37 | 1.2 | 1.6*1*1.2 |

M4-40B | 4 | 40 | 120-150 | 1.5/0.37 | 0.97 | 1.5*0.9*1 |

M4-40D | 4.5 | 40 | 180-200 | 1.5/0.37 | 1.2 | 1.6*1.1*1.1 |

M5-40B | 6 | 40 | 120-150 | 2.2/0.37 | 1.8 | 1.8*1.1*1.1 |

M5-60B | 6 | 60 | 110-140 | 2.2/0.37 | 1.8 | 1.8*1.1*1.1 |

M5-80B | 6 | 80 | 80-100 | 2.2/0.37 | 1.9 | 2*1.1*1.2 |

M5-120B | 6 | 120 | 50-70 | 3.6/0.37 | 2.3 | 2.8*1.3*1.3 |

M6-60B | 8 | 60 | 80-110 | 4/0.37 | 2.8 | 2.3*1.3*1.3 |

M6-100B | 8 | 100 | 60-90 | 4/0.37 | 2.7 | 2.3*1.3*1.3 |

M6-120B | 8 | 120 | 60-70 | 4/0.37 | 3 | 2.4*1.3*1.4 |

M6-170B | 8 | 170 | 40-70 | 4/0.37 | 3.7 | 3*1.3*1.5 |

M6-200B | 8 | 200 | 40-55 years old | 4/0.37 | 3.7 | 3*1.3*1.5 |

Step 2: Thread Roller

1. Feeding device: gear feeding, more accurate

2. Raw material processing: screw blank processing high-precision mold

3. Feeding guide rail: transport the wire billet to the design position through the guide rail

4. Vibrating plate: it can arrange and transfer the screw blanks in an orderly manner.

2. Raw material processing: screw blank processing high-precision mold

3. Feeding guide rail: transport the wire billet to the design position through the guide rail

4. Vibrating plate: it can arrange and transfer the screw blanks in an orderly manner.

Model | maximum. Screw diameter(mm) | maximum. Screw length(mm) | engine (kilowatt) | capacity (pcs/min) | weight (Ton) | Overall size (m) |

R3-20A | M2.6 | 20 | 1.1 | 350 | 0.3 | 1.1*0.53*1.2 |

R3-20B | M2.6 | 20 | 1.1 | 350 | 0.3 | 1.1*0.53*1.2 |

R4-25A | M4 | 25 | 1.5 | 320 | 0.45 | 1.3*0.63*1.32 |

R4-25B | M4 | 25 | 1.5 | 320 | 0.45 | 1.3*0.63*1.32 |

R4-40A | M4 | 40 | 2.2/0.37 | 280 | 0.97 | 1.5*1.15*1.35 |

R4-40B | M4 | 40 | 2.2/0.37 | 280 | 0.97 | 1.5*1.15*1.35 |

R5-55B | M5 | 55 | 3+0.37 | 160 | 1.2 | 1.6*1.35*1.7 |

R5-65A | M5 | 65 | 3+0.37 | 130 | 1.3 | 1.75*1.4*1.65 |

R5-65B | M5 | 65 | 3+0.37 | 130 | 1.3 | 1.75*1.4*1.65 |

R6-60A | M6 | 60 | 4/0.37 | 180 | 1.5 | 1.7*1.65*1.3 |

R6-60B | M6 | 60 | 4/0.37 | 180 | 1.5 | 1.7*1.65*1.3 |

R6-100B | M6 | 100 | 5.5+0.37 | 110 | 1.9 | 2.7*1.3*1.3 |

R8-80B | M8 | 80 | 5.5/0.37 | 110 | 1.8 | 2.1*1.55*1.3 |

R8-100B | M8 | 100 | 7.5+0.37 | 100 | 2.1 | 2.7*1.7*1.3 |

R8-120B | M8 | 120 | 5.5 | 100 | 2.1 | 2.4*1.8*1.4 |

R10-120B | M10 | 120 | 7.5 | 80 | 1.8 | 2.35*1.95*1.4 |

R12-120B | M12 | 120 | 11 | 60 | 3 | 2.45*2*1.45 |

R12-160B | M12 | 160 | 13 | 60 | 3 | 2.45*2*1.45 |

R12-220B | M12 | 220 | 15 | 50 | 3.5 | 2.5*2*1.45 |

R16-120B | M16 | 120 | 15 | 50 | 3.8 | 2.5*2.1*1.45 |

R16-160B | M16 | 160 | 15 | 50 | 4 | 2.5*2.1*1.45 |

R16-220B | M16 | 220 | 15 | 45 | 4.8 | 3.7*1.9*1.7 |

Product Details

contact us

VIEW MORE

YOU MAY LIKE

Other Products

-

Die steel wire drawing machine for nail making machine$6000.00 / set

Die steel wire drawing machine for nail making machine$6000.00 / set -

Nail and screw making machine Nail/screw making machine$8000.00 / set

Nail and screw making machine Nail/screw making machine$8000.00 / set -

High quality thread machine Machine for making self-drilling screws$5000.00 / set

High quality thread machine Machine for making self-drilling screws$5000.00 / set